Cooter7

-

Posts

9 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Cooter7

-

-

How would I go about seeing if it's picking up exhaust glasses? Should I seal off the burner holder to burner tube? I could try shortening the nozzle again didn't seem to help last time though. I don't have a co detector but when it was in the garage it was only ran short times. I now have it set up so it gets set right outside the garage when it's running

Ahh ok. Mine is satanite but probably about the same thing

-

How long does it usually take to burn of all the binder? I'm more than happy to just let it run for a while if that's what it needs. Since the last coating I've had probably 5 full heat cycles.

I can also try getting some smaller mig tips. I have double checked the ones in it and there is no bur and orifice is nice and straight.

-

-

Ok I'm just turning in for the night. I'll give it a try in the morning and report back. Thanks for the help.

-

Sorry won't use that didn't know it caused issues.

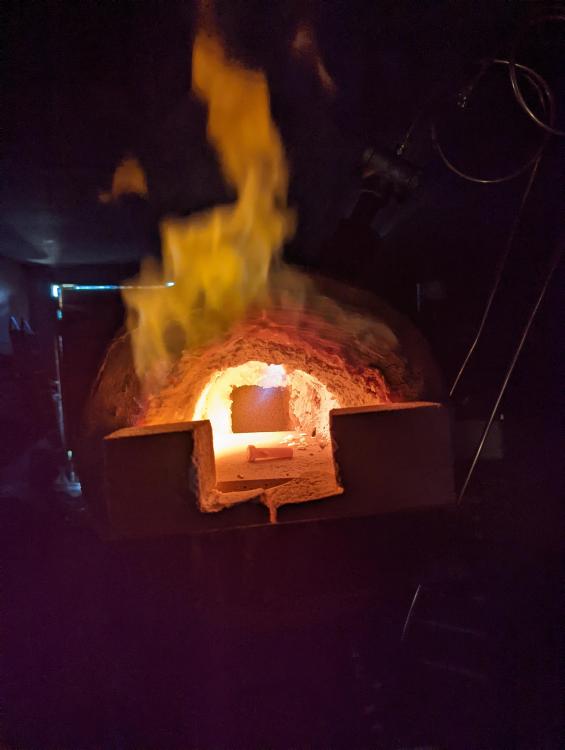

It is 311 cubic inches. It still gets about 6" of dragons breath with a single burner. Would plugging the second burner with some kaowool make a difference over just leaving the one off?

-

Just tried pulling them back farther and the only thing it changed was making the burner holder alot hotter but still had the dragons breath

-

-

I've been having issues getting my frosty t burners tuned. I have a foot or more dragons breath coming out the front. Nozzles are centered, .035, I have tried long all the way down to super short, I am running stainless 1:12 flares. I slid them up the burner tube and got slightly better results, doesn't matter if I'm running 1 or 2 burners, roughly 6x11 chamber, if I remove all fire bricks I get dragons breath out the front and back, tried 5-15 psi, 2 in kaowool, satanite, plistix 900f.

Frosty t burner issues

in Gas Forges

Posted

Ill try all that tomorrow and see how it goes thanks again for the help. You guys are awesome. I should have to in the holder to adjust if not I'll pull the fire brick out for testing to see if that's the issue