-

Posts

68 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Wandering_R0gue

-

-

I may have done past tempers at too high a heat... I think I had tried at lower temps and hadn't gotten the color draw I wanted, so went hotter. That is on past attempts though.

-

I meant that, at the proper temper temperatures, if I put it in for hours, I would move well past the colour spectrum required, and would wind up with a soft blade.

-

If I were to temper this back fir a couple hours, it would have no hardness whatsoever.... I generally find, Mayne an hour MAX for the blades I've made in the past. Why would you "retemper" a second time?

-

Fair enough, ad I didn't mean to put any words in your mouth, apologies for that.

I see your point 100%, but, in the learning process, I'm willing to take the risks for the sake of learning. Cannot learn without mistakes.

-

Wasn't that much of a waste, frosty, but I see your point. Was made with some free coil spring, so no waste there... and, I don't consider anything a failure... simply a learning opportunity.

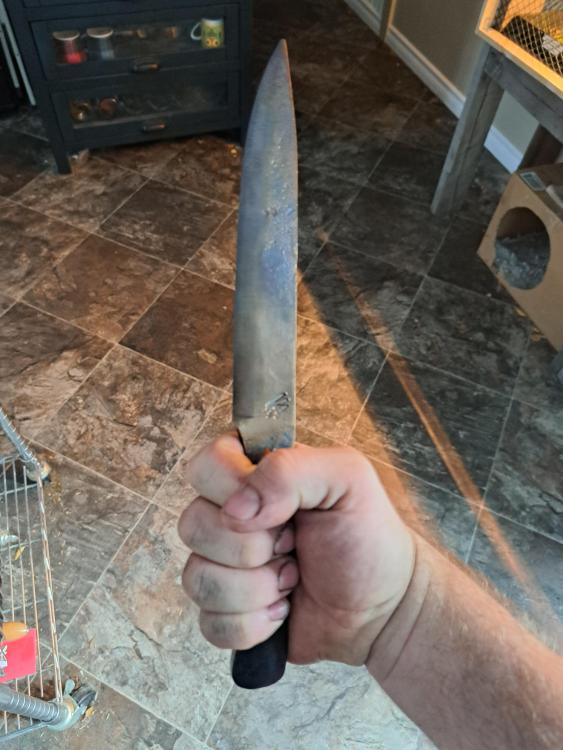

As far as heat treat on this, I have done the same several times on a few different blades/tools with recommendation from another Smith. Able to get this one shaving sharp, so it is at least able to take an edge.

-

I hear you. I run a charcoal forge too, so reaching, and maintaining a proper temperature gets a bit finicky. But, it is all a learning process.

-

thanks, this will be my first slab-scale knife.

-

Banged out a blade this weekend. Got heat treat done, but I was second guessing myself, and ended up doing it a couple of times. I'm still trying to figure out what best temper/heat treat is for knives from this material for best edge retention and durability.

Next step is adding handle and finishing.

-

On 7/14/2023 at 2:08 PM, Shainarue said:On 7/2/2023 at 9:09 PM, Wandering_R0gue said:

That's a slick lookin sword. I love the hilt design.

Thanks! I'm really happy with how the guard turned out.

-

3 hours ago, Chad J. said:

Very well done for your sword Rouge. What were your inspirations for the design?

Partly what the metal did for me, partly what my wife wanted in the design. It is sort of a mix of a cutlass and a falchion.

-

Finished all but for sharpening. Next step is the scabbard.

I learned a lot of things in this build that I will apply next time. There are some quirks, and issues with this one, but for the person it is going to l, it will do, and they like it.

Final weight, 1lb 12oz.

Overall length, 26", blade length, 19 inches

-

"Very nice, WR. It’s got a lot of character."

Thanks JHCC. I'm pretty happy with it fir a first ever sword. Learned/tried lots of new skills on this one.

-

-

True, but, for now, It is what I have.

-

Working on a sword blade, and I wanted to run some fuller. Since I have never done that before, I wasn't 100% sure how. I don't have any stages or fullering tools, so I opted for grinding in. However.... my option were an underpowered belt sander, or an angle grinder.

I didn't want to OOPS and destroy a project with the angle grinder, so, I started with a dremel, cut a start groove, moved onto a stone grinding tip, then a sanding tip. Once the fuller was significantly large/straight/deep enough, I needed to find a way to expand it, but still maintain control.... so, I built a tool.

It runs in a cordless drill chuck, and I can control/apply pressure with my off hand due to a grip I added. Allowed me to sand/grind the fuller better and maintain control, with minimal damage if I slipped.

-

Just ran my first fuller. Far from perfect, but cleanable. I started with a Dremel to start the cut, then went with progressively bigger grinding tips. Wanted to maintain as much control as possible.

Got the other side roughed in. Much straighter than the first.... straight edge guides are a good thing.

I need to draw out the tang a bit still to allow for a longer grip...

Think I'm going to build a temporary long trench forge for the heat treat because i cant heat the full thing in my forge.

-

-

-

Made my first set of tongs today. Was a bit of an adventure, and they're a bit rough, but will functionfor their purpose.

Everything is a learning opportunity, and I take even the disappointments in stride. Had everything almost ready to rivet together, but while punching one eye, it cracked and I had to completely remake a whole piece.

On 12/1/2022 at 10:04 PM, Shainarue said:Looking good! Looks very clean!

-

I have a charcoal forge Inside my shed. I ran a chimney through the roof, so I can close uo the doors and it gets comfortably warm. We shall see what it is like come -40°C later this winter.

-

-

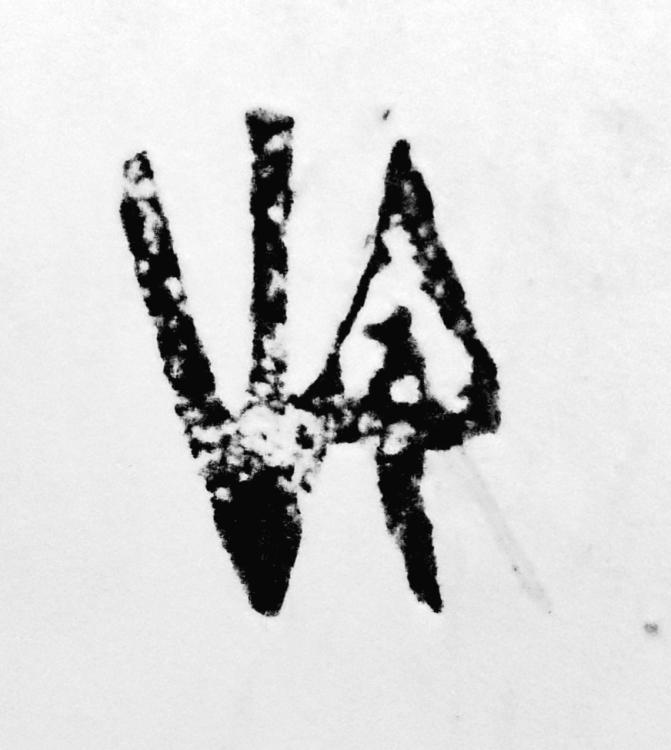

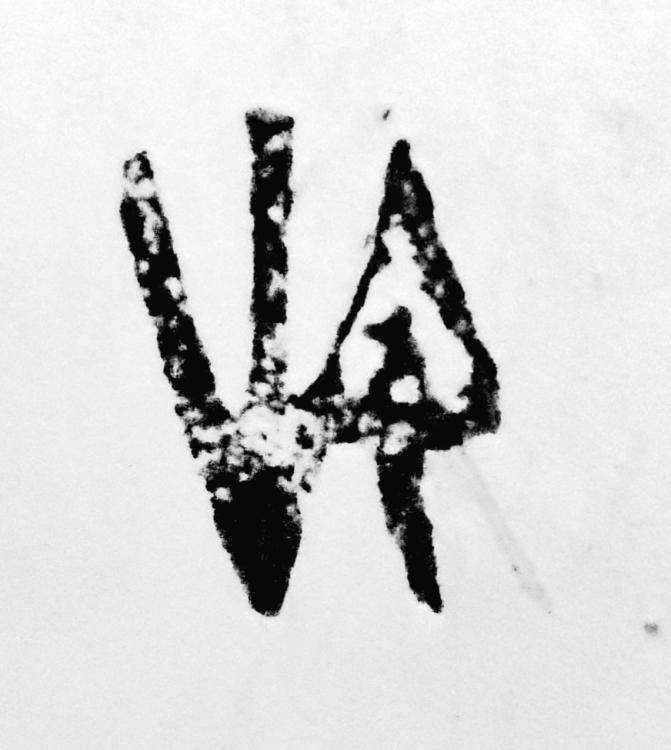

Almost didn't remember... and I etched it right way round on the too so I'd know which way is up.

-

Today's forging adventures....

Made myself a touch-mark, and a chisel. Both currently tempering out, then I will sharpen and handle the chisel.

First time in a long time doing winter forging, but was able to get the shed from -15°c to +5°c just with the forge. Started off in a heavy sweater, finished in shirt sleeves.

-

What did you do in the shop today?

in Blacksmithing, General Discussion

Posted

I thought this was supposed to be a resource for people to ASK questions and seek answers from there in the space? If not, then why are any of us here?

I recognize experience, and was simply stating mine, and asking questions so as to better understand.

Everyone was a beginner once... and very often, the problems I find with forums like this, is that there is co flicting information, Everyone is convinced that THEIR way is the right way, and instead of trying to explain something it devolves into an argument...

Really makes it discouraging for any new makers to want to engage.

Just my opinion, I take no offense at anyone else.