-

Posts

33 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by victorforge

-

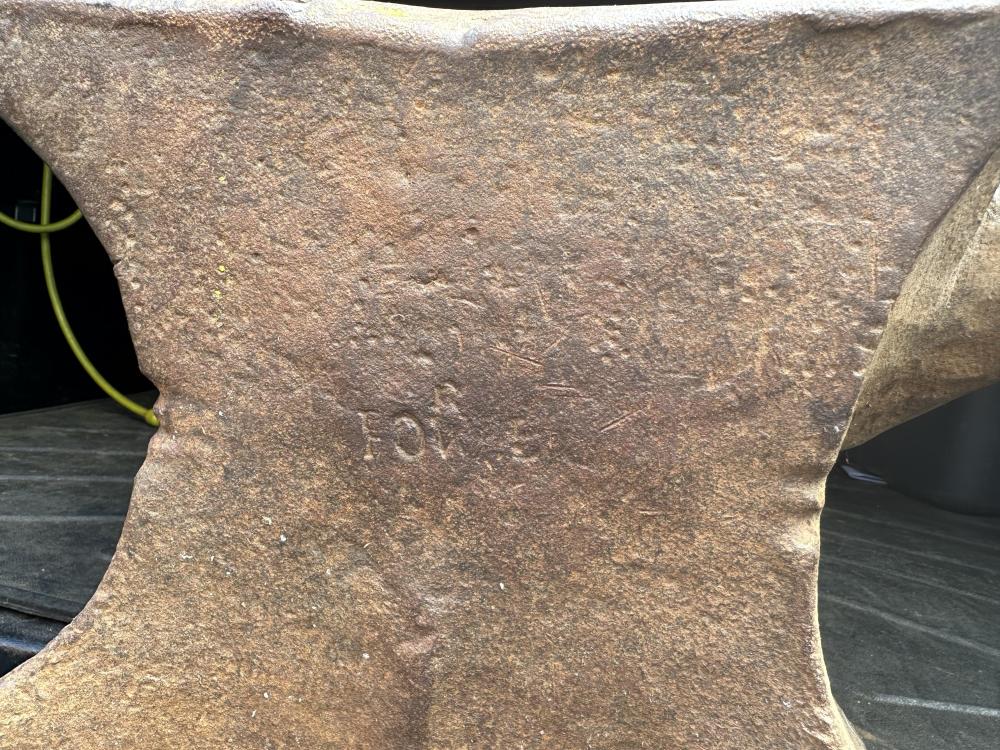

Colonial anvil marked Powe

victorforge replied to victorforge's topic in Anvils, Swage Blocks, and Mandrels

“Ive done a bit of research into the Hill Family. Working backwards this is the business succession as i have determined. Isaac Nash aquired from John Powell, John Powell aquired from CW Hill via bankruptcy. CW other brother Thomas aquired it from brother Isaac Hill jr via inheritance. Isaac Hill jr aquired from father Isaac Hill Sr via Inheritance. Isaac hill sr came to Birmingham shortly before the birth of Jr in 1793 from Bruton, Somerset, England. Richard Hill was operating in Birmingham as early as 1778 with trouble expirencing multiple bankruptcies. To summarize, I've not connected Richard, Isaac, or D Hill. Id like to see if R Powel is an ancestor of John Powell.” From Travis Elliot on facebook -

Colonial anvil marked Powe

victorforge replied to victorforge's topic in Anvils, Swage Blocks, and Mandrels

My hypothesis was correct. John Powell purchased Issac Hill's forge after his death. I would like to find out if Richard Hill was Issac Hill's father. I wonder if my anvil, having the mark of "R" seen on anvils marked "R Hill", was old stock that they stamped Powell over the Hill portion and sold it. -

Colonial anvil marked Powe

victorforge replied to victorforge's topic in Anvils, Swage Blocks, and Mandrels

I've done some research. This is what I've found, John Powell made anvils, vises, bellows, and forges. The earliest mention of him as an anvil works is in 1862. The location of the works is Oxford Street, Digbeth. I have a hypothesis. Isacc Hill was an anvil maker in Digbeth up until the 1850s. Richard Hill was an anvil maker around 1770 also located in Birmingham (where Digbeth is). My hypothesis is that John Powell may have worked for either of them and eventually purchased the anvil works from them. Anvil Fire has a picture of a sort of stake anvil marked "R Hill". If you look at the markings on my anvil, it bears the same R above the name. -

Colonial anvil marked Powe

victorforge replied to victorforge's topic in Anvils, Swage Blocks, and Mandrels

I already searched this site and found no meaningful information on John Powell other then the existence of later anvils. This anvil was likely made prior to 1780 due to the lack of a shelf. My guess would be early 1700’s based on the use of a simple center punch to create numbers for it’s stone weight. It was mentioned in another thread that Richard Postman knew of Powell anvils. Unfortunately, there’s no mention of them in Anvils of America. -

I need help dating and identifying my anvil

victorforge replied to SkyDaddy66's topic in Anvils, Swage Blocks, and Mandrels

I’d say that anvil was made probably between 1800-1830 based on the horn having a table. Probably made in England. -

Colonial anvil marked Powe

victorforge replied to victorforge's topic in Anvils, Swage Blocks, and Mandrels

Update: No mention of anything similar in Anvils of America. My friend has a hornless double arch with the same marking. It seems the markings spell out Powell or something similar. I need to do some deep investigation into it’s origins. -

Acquired another colonial anvil just south of Harrisburg, PA today. It’s marked Powe on the side. I’m wondering if its a Powell. Any idea when he started making anvils?

-

Using satanite as mortar for kastolite

victorforge replied to victorforge's topic in Insulation and Refractories

That's why I thought of using satanite as sort of a binder between the two. Such as applying a thin layer of Satanite to the kaowool and then apply the kastolite on top of that while it's still wet. I'm just going to make a liner for it. Last time I mixed it, I used 13oz of water for every 5lbs. -

Using satanite as mortar for kastolite

victorforge replied to victorforge's topic in Insulation and Refractories

I'll give that a try. I tried using it before and it just wouldn't stick. I've got a bunch lying around so might as well use it. Thanks for the help. I'll just use cardboard to make the inner form. Maybe 3d print a sort of frame for the cardboard. -

Refractory question. Relining my Mr volcano forge. I have satanite and kastolite on hand. Kastolite is rather difficult to apply in this case. Since satanite is a mortar, could I mix the satanite with kastolite to get it to adhere to the kaowool or could I apply the kastolite on top of wet satanite? Otherwise, I’ll just order greenpatch or plistix. (Any idea if one is better then the other?)

-

Jer Schmidt's 2x72 belt grinder build

victorforge replied to victorforge's topic in Grinders, Sanders, etc

I'll attach an hour meter for scientific purposes. -

Jer Schmidt's 2x72 belt grinder build

victorforge replied to victorforge's topic in Grinders, Sanders, etc

My 2 dewalt grinders have a rather fine mesh on their ventilation holes that seems to work. -

Jer Schmidt's 2x72 belt grinder build

victorforge replied to victorforge's topic in Grinders, Sanders, etc

I'll probably get a used/surplus TEFC 2hp from a nearby industrial surplus place in the future. That's a good point. My cheap angle grinder has exposed coils and has been through XXXX Yet its still chooching. I wonder if I could put a thin mesh filter over the openings. I'd have to watch the temperature though. -

Jer Schmidt's 2x72 belt grinder build

victorforge replied to victorforge's topic in Grinders, Sanders, etc

I’ll just run it till it dies. I’ll probably replace with a VFD and a better motor in the future. -

Jer Schmidt's 2x72 belt grinder build

victorforge replied to victorforge's topic in Grinders, Sanders, etc

It's rated for continuous use. It's not TEFC rated but it is ODP rated. -

I've begun the process of building my first 2x72 belt grinder using Jer Schmidt's plans. I purchased his gen 1 plan a few years ago but never got around to building them. Schmidt's plans are fantastic. I had some of the parts water cut at the cost of an anvil. (I actually made out with this trade) Took advantage of a presidents day 20% coupon at the Horrible freight and bought their 2hp motor for it. I still have to buy all the fasteners, wheels, and belts. I got spring break coming up so hoping to knock it out that week.

-

Colonial anvil identification

victorforge replied to victorforge's topic in Anvils, Swage Blocks, and Mandrels

Ordered the book along with Anvils in America as soon as I bought it as i figured it was a mousehole. -

Colonial anvil identification

victorforge replied to victorforge's topic in Anvils, Swage Blocks, and Mandrels

-

Colonial anvil identification

victorforge replied to victorforge's topic in Anvils, Swage Blocks, and Mandrels

-

Colonial anvil identification

victorforge replied to victorforge's topic in Anvils, Swage Blocks, and Mandrels

Kept looking for markings and finally figured out it's stone weight. It's marked "0" "3" "20" so 104lbs. The 3 was difficult to see. I finally got a copy of Anvils in America and it seems to have similar shape to some in there. I'll wire brush to see if anything else is hiding. -

Colonial anvil identification

victorforge replied to victorforge's topic in Anvils, Swage Blocks, and Mandrels

Picked the anvil up today. Paid $400 for it. Only real visible marking was a "20" on the side toward the right. Weighs 100lb. Definitely deceiving size for its weight. Great shape for its age. I found a larger very similar looking anvil online. Link removed -

Colonial anvil identification

victorforge replied to victorforge's topic in Anvils, Swage Blocks, and Mandrels

Lower bucks, Yardley to be specific. Id love to visit. -

Colonial anvil identification

victorforge replied to victorforge's topic in Anvils, Swage Blocks, and Mandrels

I've been told around 80lbs. I located in SE Pennsylvania. -

Large Anvil identification

victorforge replied to victorforge's topic in Anvils, Swage Blocks, and Mandrels

It was to big for me, also had a crack in the horn. I broke a little over even on it which was good. I don't have a dedicated space to blacksmith in right now. I need my tools somewhat mobile. My garage is mix of classic cars/motorcycles, lathe, and tools. If i want to forge I got to move my dedicated tool cart and anvil over to one bay and roll my utv out. Not optimal but got to work with what I got. -

Poor quality photo from seller but picking this up Saturday. No pritchel hole so before 1830. Mousehole style pointed feet. Handling hole on each side.