Daren.McIntosh

Members-

Posts

7 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Clarkston, MI

-

It’s been slow going, but I’ve got the refractory pretty well cured and coated with Plistix. Doing short test fires now.

-

Lucky, have you been able to weld with a NARB forge? I’m not planning to weld up huge stacks of Damascus regularly, but I was hoping to stick a few pieces together for some upcoming projects.

-

Makes sense. Thanks Frosty. Here are some closer shots of the flame. most of these are at 1-2psi. The longer flames are 4-5. I’m digging how quiet this thing is. Hopefully I’ll get time to start rigidizing and coating wool this weekend.

-

Thanks for all of the feedback. I installed the shorter pipe to great success. (Second pic.) Then I shortened the mig tip to 1/2 way. (First pic.) Buzzkill, I had planned on mounting the burner along the floor, not thinking that direct contact would be much of an issue given that these flames are not quite as intense as a single orifice burner. If that setup would be particularly detrimental to the steel, I can mount it higher and deal with the burner tube being angled. The plan was to use ceramic wool under the floor with a decent layer of refractory on top to protect it.

-

The tube was 8” long for some reason, thanks! I grabbed a 6” nipple on the way home from work today. I’ll try to make time to fire it up tomorrow. There is no diffuser in this burner, I figured splashing off of the other side of the plenum would be sufficient. As for the forge, I really liked the idea of Eric Fleming’s ribbon burner table forge. But, like Buzzkill, I was not a fan of the floor space lost to the burner. My plan is to mount the burner on the side. The forge body has a 7” diameter chamber. With the flat bottom, the height is 6”. According to this Partial Cylinder Calculator, the volume should be 350ci. The plan is to allow for different forge bodies in the future without completely tearing apart the forge. The floor will be cast and the front/rear “porch” areas will be replaceable firebrick. The green patch says it is good for up to 3” depth, but if I were to do it again, I would likely cast it in layers as I did get some warping/shrinkage. If I do that in the future Frosty, I may do as you say and make the first layer as a heat shield.

-

Thanks for the questions and feedback. It’s good to know that the bright yellow flames are more likely running rich than just a product of burning without back pressure. At this point, I’m just pleased that I didn’t blow up or break anything. The burner is a standard 3/4” Frosty T design that I built 3 years ago, and never tuned. I can’t remember what tip is in there, most likely whatever is recommended in the build instructions, but never trimmed or adjusted in any way. The photo with less flame is 2psi, more flame is 10 psi. The plan is to side mount this in a table style forge with the top being half a party balloon tank. I wanted a “convertible” forge because I am interested in ornamental iron work and art pieces, but I am not currently interested in burning coal, and didn’t want to be restricted to a tiny forge opening. I’ll mess with it more when I get home tonight. I had all this figured out enough to start building it years ago, now I have to go back and re-figure out what I was thinking. I can’t remember my intended forge volume.

-

Daren.McIntosh started following One more newb NARB.

-

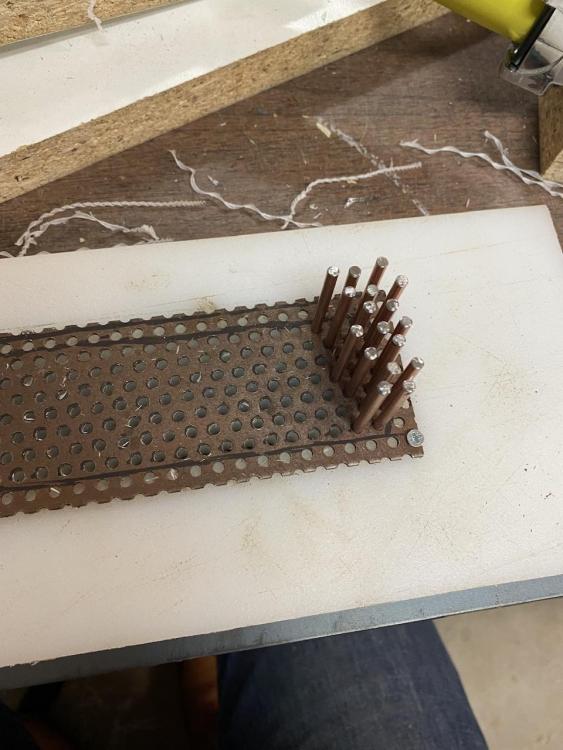

After reading all 42 pages of Frosty’s 2016 thread, I decided to try to cast a NARB with a WHOLE BUNCH of 1/8” holes. Something like 135. I found a chunk of perforated plate in the scrap bin at the metal supplier. I used that as a jig to hold greased up 1/8 filler rod for the sprues. The refractory is Greenpatch 421. No idea how that’s going to go. I’ve been dragging my feet on this project forever, but I’ve finally got the thing together and shooting flames. I don’t have my forge finished yet, so I can’t judge it in its natural environment, but I am pretty happy with what I’m seeing and hearing so far. I’ll post updates as I go. Feedback is appreciated, by all means, if you see something, say something.