vespdrone

-

Posts

15 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by vespdrone

-

-

2 hours ago, JHCC said:

Those are some nasty chips, but there's also a decent amount of good edge still on that thing. I'd recommend leaving them alone for now and working around them as much as possible. You might want to do the absolute minimum of grinding to take off any sharp edges, but I wouldn't do any more than that at present.

That seems pretty sound advice - I agree it's perfectly usable for now. My main worry would be causing new cracks, so I'll keep away from existing ones.

-

On 10/27/2021 at 9:31 AM, jlpservicesinc said:

Any layer or anything between the face of the anvil and the ball bearing will skew the results.

It needs to be clean shiny metal to get decent results. this means no rust or oil or wood dust or even regular dust..Thanks for this information - I didn't quite appreciate how clean it needs to be!

The light blue looks spot on, after seeing one recently! There's tinges of red and dark blue I'm less sure about

-

On 10/27/2021 at 9:26 AM, Rojo Pedro said:

I would suspect the ball first. It needs to be a hardened steel ball bearing.

My ball bearing gets about 50% or more on my mild steel improvised anvil.

Oh great! I'll look for something that mentions hardened steel. That's a great result - I'll stay positive

The pitting was much worse at the start, almost felt lumpy.. but with use it's getting better and better.

Thanks Rojo!

-

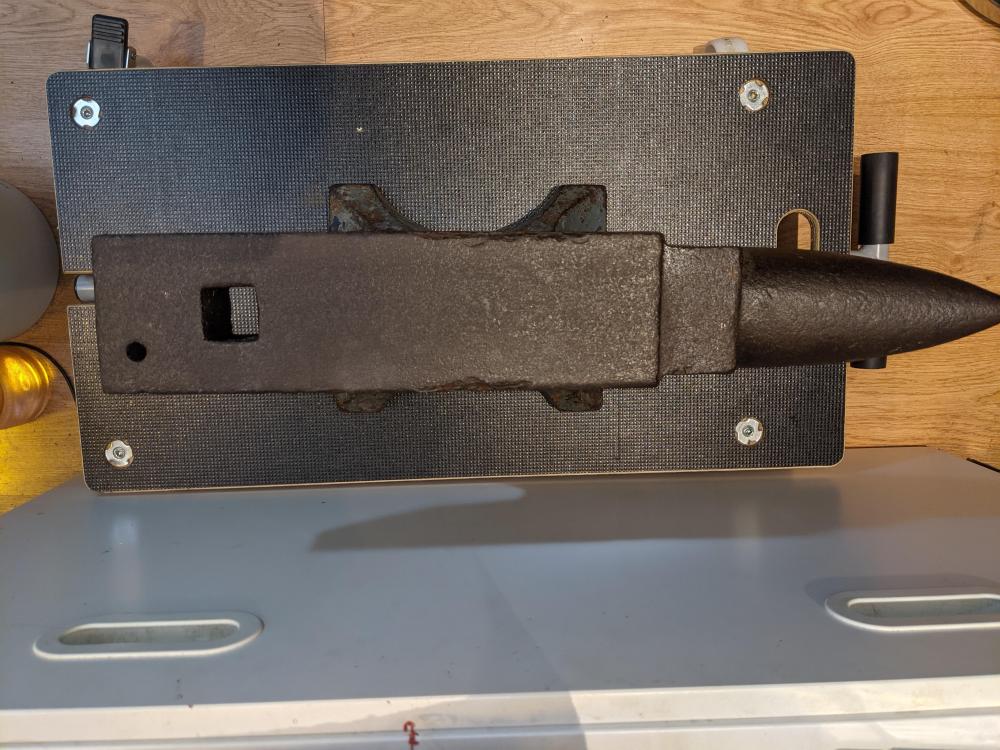

Hi all, I posted pictures of my second hand John Brooks anvil in the show me your anvil page -

I wanted to ask what you would do if you received this anvil - as you can see both sides are chipped, although one side isn't as bad

Besides the chips, around the heel of the anvil looks a bit mushroomed, so I need to radius the whole way around for sure.

I figure I could do some wide radii around the chips - I'm afraid to put any work near them right now

What would you do?

-

I love to show off my anvils - here's my John Brooks anvil. It's my second anvil - wanted another because my brothers are involved too, and having one anvil sucks!

It was a shot in the dark - 350GBP for 50kg but they did me a deal on a post vice. The face was quite course with rust, but that went with some use. I found even running my hammer over the face would leave a reddish trace of the rust, so I did it over an evening and noticed a massive improvement. Simples!

I did a rebound test when it got here, and was a bit disappointed - after putting in the offer I read the warnings about shop fires.. but sure look. It might be 30% or so. I keep meaning to test my new peddinghaus, thinking maybe I can blame the ball bearing! All that said, it works well enough for us.

The chips are pretty bad on one side, but no one has ground radii into it before. I've heard cast steel JB anvils are notorious for it.. I'll make the cracks large radii.

All this said, I'm still chuffed! I use the JB anvil at home as it's 25kg lighter, and it gets moved around a lot

-

1 hour ago, Nodebt said:

Welcome Vespdrone.

Forge/Shop withdrawl can be ugly. I'm learning repousse on a small old stump with a bunch of leather tacked on it until I can get myself set back up.

Ah cool, that's an interesting technique. Hope you get back up & running soon.

3 hours ago, ThomasPowers said:When I had a 90 day business trip to Germany; I brought along a billet and a "sample box" of borax and was able to find a working forge at an open air museum that would let me forge as a demo.

That was lucky! I'm trying to imagine what the most minimalist holiday forging pack would look like now..

-

1 hour ago, ThomasPowers said:

I was sitting on an old kitchen chair with my small, 40kg, anvil between my knees on a stump. I forged all the iron fittings for my version of the Mastermyr Chest using it and then hot forged sterling and fine silver viking era jewelry, hack silver and penannular brooches.

It was a bad winter and I was undergoing forge withdrawal!

That's a great image! It's amazing what's possible even with a blowtorch, I'll have no excuse not to practice!

-

52 minutes ago, ThomasPowers said:

You can pass the American Bladesmith Society's Journeyman test with a knife forged from auto leaf spring! Of course you want one with as few miles on it as possible and NEVER one picked up broken on the side of the road!

When I was weather restricted, -20 degF (29 degC) windchills, I built a "one soft firebrick forge" that ran off a plumber's propane torch and did a winter forging small items in the drafty basement of our house.

Nice, that is encouraging

That one brick forge sounds cool. I must try something like that. Going to try wedge my anvil in, and have it nice and quiet before starting that

-

14 hours ago, Goods said:

Welcome aboard!

For high(er) carbon steels check with a couple auto repair shops. Coil springs, left springs, swing arm, drive shafts will all make good tooling. Test it, some may make good knives. Also see if there are any local machine shops. They may have drops, or they could even add to their orders for you if you get in good with them.

Some manufacturing facilities have outsourced there tool and die repair, so sorting though a die/mold builders scrap bin can be pretty rewarding…(You just need to get a really good feel for more advanced tool steels pretty quick.)Keep it fun,

David

Thanks David, this is wonderful advice. We have a friend in a garage who keeps coil springs now for us. He hasn't had leaf springs in yet. I must call around. Great tip about machine shops and drops / ordering!

-

Stumbled across this section while browsing the threads

I'm Thomas - a newb based in Ireland.

My brother acquired a Devil Forge propane forge and can't fire it up where he lives (or at mine) so we fire it up at a family members house. We don't get out as much as we'd like, but very much enjoying it!

As we can only setup outside, our forging prospects depend on the weather! I'm preparing myself for disappointment over winter when rain buckets down! I picked up some 1/4" copper to do some cold forging at my own home.

For steel stock - we can get black mild steel easily, but tool steel is posing a challenge! The biggest two suppliers don't stock tool steel, and won't order it in unless I want to order thousands. When I found a supplier with some W1 in stock I bought what I could afford since it doesn't sound like they'll order it again

Looking forward to getting to know people here, especially in Ireland!

-

26 minutes ago, ThomasPowers said:

Blue was Brooks IIRC; but as you say the paint could be a later add on. Test: ring and bearing ball test; if good jump on it. If ok: Haggle!

Thanks for your answer! The seller responded, it might have been done by his father after acquiring at an auction.

I'll research Brooks and hopefully see something close.

Lovely, thanks for the suggestions. I'll try these out on my own anvil for a reference and check online.

-

17 minutes ago, JHCC said:

If the price includes the swage block, the cart, the fuller, the tongs, and the coal shovel, get thee thence, test the ring and rebound, and if it's in good shape, buy it. The manufacturer is irrelevant.

I'm very much leaning this way - it looks like a great kit, and I'm just starting out. I do already own an anvil but there's a couple of us and this has a lot of extras. Thanks for the advice.

-

I'm browsing local sale websites for deals and I noticed this anvil and swage up for sale for a price you'd see for an anvil on it's own. The lots being sold for €500.

I wonder if anyone recognizes the make of the anvil?

I'm thinking the paint may not be original as the swage and cart has it too.

I asked the seller about the weight, any marks or branding and what he knows about it, waiting on a response.

Based on the ruler the face is approx 14" long, 4.25" wide, the horn approx 6.5" long, the plate about 2.5". About 23" in length, 4.25" in width? Its hard to tell how tall it would be

-

If you found this thread and the links aren't working, try searching archive.org for them

Practical Blacksmithing by Milton T. Richardson https://archive.org/search.php?query=Practical Blacksmithing Richardson

The Blacksmith's Guide by JF Sallows https://archive.org/search.php?query=The Blacksmith's Guide

Forge Work by William L. Ilgen (1912), https://archive.org/search.php?query=Forge Work William L. Ilgen

Grind out the chips? What would you do?

in Repairing and Modification to Anvils

Posted

I guess I was wondering if there's interesting "modifications" people have done in place of cracks. But I guess the best modifications depend what you're using it for!

Thanks for the advice!

Wow, that's a gradual fix alright. I'll keep this in mind, thanks!