Mario prefontaine

-

Posts

6 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Mario prefontaine

-

-

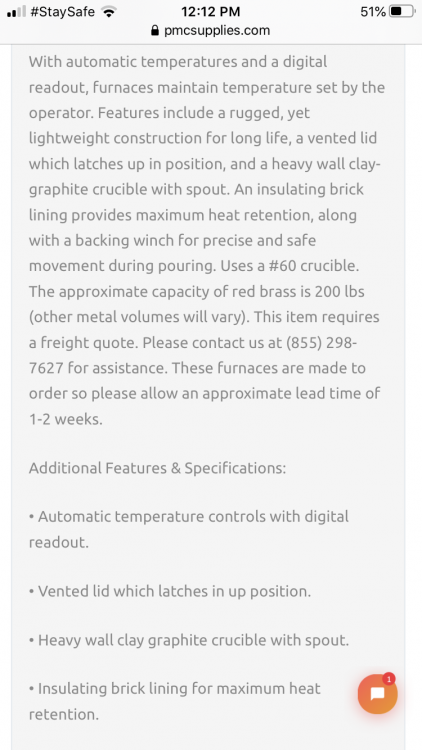

Hey, so my knowledge in forges and smelting is pretty minimal. But my goal is to have a forge big enough to be able to melt 45 lbs of cast iron in one crucible. My goal is to be able to sand cast 45 lbs dumbbell plates. There is a unit that I found from a company in USA called pcm supplies. I phoned the company and they say that the forge I was looking at would get to the melting temps I would need, but it says that the forge runs on 110 volt 3 prong standard plug in. I just have a hard time believing that with 110 volt I would be able to reach those temps. Would anyone have experience smelting and casting cast iron? And what do you guys think of this forge?

I have attached a picture of the electric furnace and it’s description.

-

Sorry I forgot to answer your question about coal, we have lignite coal. And thanks for the link looks like I will get some good ideas from there.

-

Ic, k well a foundry is what I’m looking for, and I just figured I would have more access to steel than cast iron, but I probably could still find quit a bit of cast iron too. And if I do buy a foundry that that can at least melt iron. I’m thinking I would get that electric foundry that pcmsupplies has.

-

Sorry I’m fairly green with metal melting, I used a small propane forge before for casting copper, that’s about the extent of my experience. Also I’m in southern Saskatchewan, coals not very good, but it would be free. Also I would like to be able to have a forge were I could just go to our junk hill and cut up old farm machinery to be able melt that down and cast weight plates.

-

Hey, so I have been looking into forges that could get hot enough to melt about 50 lbs of steel in one crucible. I have looked into induction forges, but I’m looking at paying around 50 grand. I found a electric tipping table forge that would be perfect, only problem is it only heats up to 2300 F. I would like to keep this project at around 4-6 grand to build or buy. And my main purpose of this forge is I would like to make 45 lbs weight plates and dumbbells. So far my best options would be a big homemade coal forge( I work at a coal mine so coal will be cheap). Also this arc welding forge, but I haven’t found anyone who is confident enough to build one for me. Any suggestions or advice would be great thanks.

Electric forge for casting 45 lbs barbell plates

in Smelting, Melting, Foundry, and Casting

Posted

No, I have not really looked into cast iron melting cupola. I will have to do that, also I’m ok with spending around 6000$ on this project, and it just seemed from a beginner perspective, that the electric would be the most Efficient. But I could be completely out to lunch. And thanks for clearing that smelting and melting. I was getting a lot of xxxx for mixing up my terms.