Hawkbox

-

Posts

54 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Hawkbox

-

-

Huh, that's fascinating and I really like the design Skidpad did up just to help wrap my head around what was being talked about. If it ever warms up enough outside that my water bucket in the garage thaws out I'll have to go down this rabbit hole again.

Regarding 3D printing nozzles, I have to imagine that's not on your bog standard Ender 3 Pro unit? The tolerances seem like they would be far to fine for your average home use printer?

-

Are you looking for one to have running continuously or just to kind of eyeball it? I built a digital one because I don't believe my forge is getting hot enough and I don't honestly think my eyeball is telling me the same colour as other peoples eyeball.

I found a design that suited my needs by googling "Forge Pyrometer" and it was a site from Caffrey Knives. If you have any electrical skill at all it should be a fairly simple PID setup. I had to swap the various part options out, that particular PID unit he recommends is nowhere to be found in Canada but really any controller that will do 1300C readout should suit your needs.

I was able to put together one for around $60CAD which should be under $40USD if you look around. Or if you found a prebuilt one you're laughing.

-

You know what, I think I'm done here. I'll figure it out on my own. I'm sorry I don't know the specific search terms and hope to get something approaching help in a non condescending manner. Clearly I was delusional.

-

I'm now confused too, K-26 shows a 2600F fire rating while the ones I'm told are no good have a 2800F rating, which is somehow worse?

-

Thanks Mikey, I'm reasonably sure I can find Perlite. Yup good old Canadian Tire has it.

-

I would love to do it right, but this sites fixation on not linking other sites and vague suggestions to google do not help.

I've spent days trying to find Canadian suppliers for anything recommended on this site, Plistex and Matrikote might as well literally not exist in Canada, Kast-o-lite is out of stock in the one place that lists it, not a single site I've been able to find specifies if a firebrick is K-26 or anything at all.

I'm entirely open to suggestions but the idea that it's straight forward to find what Americans can easily get there hands on here in Canada is entirely not the case. The local blacksmithing group has no more access to the materials than I do so I am entirely at a loss of how to proceed without either waiting for shipping and duties from the US for however long that is or trying to work with the materials available to me.

-

-

A better price than the Chinese option at any rate.

-

Huh, that was the only one I could find that was in the $6 range and they wanted $120 CAD per brick in shipping charges.

-

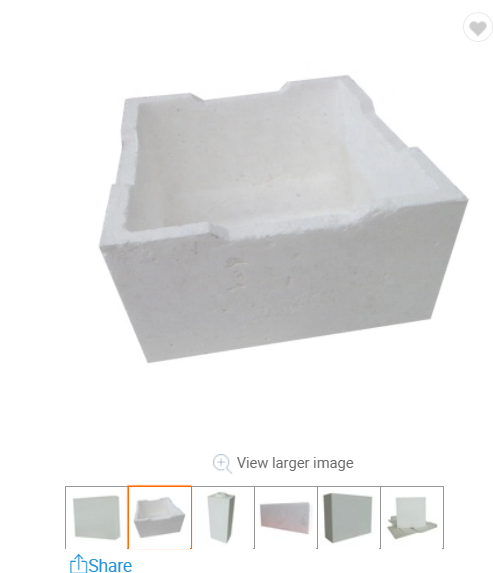

Are we talking these Mikey?

-

I saw your post in the forge thread and googled it. I assume you mean the site that has a relationship with the 40 thieves and I only saw what looked like tubes of it there?

-

Those sound neat. I'm struggling to map in my mind what they will do.

-

On 1/13/2021 at 8:00 PM, swedefiddle said:

Front Step Forge, Shaun Cunningham

It's not strictly on topic but I wanted to touch on this, I ended up taking the course over the weekend and he is incredibly friendly and knowledgeable. I've signed up for the next one too, didn't strictly help my forge heat but man did it educate me on a lot of basics around technique.

Really appreciate you pointing me in that direction Swede. Deimos, that looks great.

-

I was working K-12 IT during the time and could have made triple my salary if I wanted to go work those jobs as people who could count and show up reliably were even more prized but I had absolutely no interest in going back to that kind of work after I stopped apprenticing. I'd have ended up with a massive cocaine habit just to stay awake I can picture it.

I felt for the guys doing it but so many of them were wildly irresponsible with the money so when things tanked in 2008 most of them lost almost everything.

-

Yeah I was a volunteer firefighter from 2005-2008 during the boom here and the amount of oilfield workers that got killed just going to and from the site was staggering. Working 16 hour days then drive 2 hours each way, get 3 hours sleep and go back out. The worst one I know of was the guy who ran a stop side and got creamed by a logging truck, his legs stayed in the drivers seat and his torso was now in the passenger seat. Thankfully I missed that call.

-

I found that yesterday conveniently enough, I see their is an intro blacksmithing course tomorrow starting so I'm going to see if I can get myself into that. Looks like he is teaching it so good opportunity to learn some stuff while I get my tools and gear sorted out.

-

When I hear Americans talk about doing well site work it terrifies me, even as lax as we can be we'd get shut down doing the things our guys in Pecos talk about doing. We have/had a site in Dickinson North Dakota and my network minion has gone a couple times and we're just amazed at how much they got away with that we'd get pinned to the wall for.

The safety standards seem to be lower than the ones I worked with in the 90's here in Alberta, and we're pretty half assed by Canadian standards.

-

49 minutes ago, SLAG said:

All that I do is to type in 'mudlogger' def. And Voila,

I was being conversational, but thank you for the condescending response. It really makes me want to participate in this forum.

37 minutes ago, ThomasPowers said:Basically an entry level geology job that was opened up to anyone during the boom. About the time I would qualify to be the geologist sitting at his kitchen table drinking hot coffee and taking the reports the oilpatch crashed. I remodeled a house and then apprenticed to a swordmaker for a year.

That makes sense, lot of it became swampers up here (Basically grunts who climbed under the platform to do manual labour) and was a favourite of high school drop outs who wanted a lifted truck and a cocaine problem. It's interesting the terms, I worked with some geologists here in the late 90's and never heard the term used.

-

I worked as a Millwright apprentice for 2 years 20 years ago so know exactly how bad those roads are, a corvette at all on those is asking for it.

I'm not familiar with what a Mudlogger is though, not a term I've heard before.

-

I know my cheapo channel locks are not great for this so gotta learn some skills quick to learn to build some tongs.

-

Learn something new every day. I grew up with race horses so I'm familiar to a degree with various farrier bits and terminologies that don't quite overlap either.

Plus side the neighbour had no issue with me getting the 2 coil springs he pulled out when lowering his wifes SUV for who knows what reason.

Edit: Relevant question, I have 2 pieces of refractory board I'm planning to make doors out of, I assume I will want to rigidize and coat them in refractory too? They seem like they will have the same fibre problem the wool does.

-

Gotcha, thanks. I think I can see what you mean about them being challenging to use.

-

My only knowledge of reins is around horses... I feel like that's not an accurate interpretation.

-

It never even occurred to me to think about making Hardy tools. I was picturing handles, hooks, etc... but yeah there is no reason you couldn't make the hardy tools now that it occurs to me.

Edit: Thomas replied right as I hit go, I never attempted quenching it. We had tons of it on the farm and I haven't touched it in years I just remember using it and cussing trying to stick weld it. With the covid and the farm being 5 hours away I haven't gone since October but the next time I'm up I'm going to go scavenging.

I might be wrong but just the idea of using 3/4" handles for tongs makes my hand cramp. I also grew up hammering nails and fencing every summer so my technique with steel needs work but my hammer skills are excellent.

Lug wrenches do seem like they would be fantastic material for that purpose, other than buying them new is prohibitively expensive. I need to refill my 30lb propane tank today (I figure I got about 6-8 hours total burn out of it) and it gives me an excuse to do a tour and look for anywhere I might be able to score scrap steel.

Burners 101

in Gas Forges

Posted

Oh you're using the nozzles for the 3D printer, yeah that makes more sense. I was trying to figure out why you were 3D printing nozzles.