Adamsnj112

-

Posts

22 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Adamsnj112

-

-

Mikey, the forge measures about 8.5” diameter and 20” long with the ceramic plate just below centerline

-

Frosty,

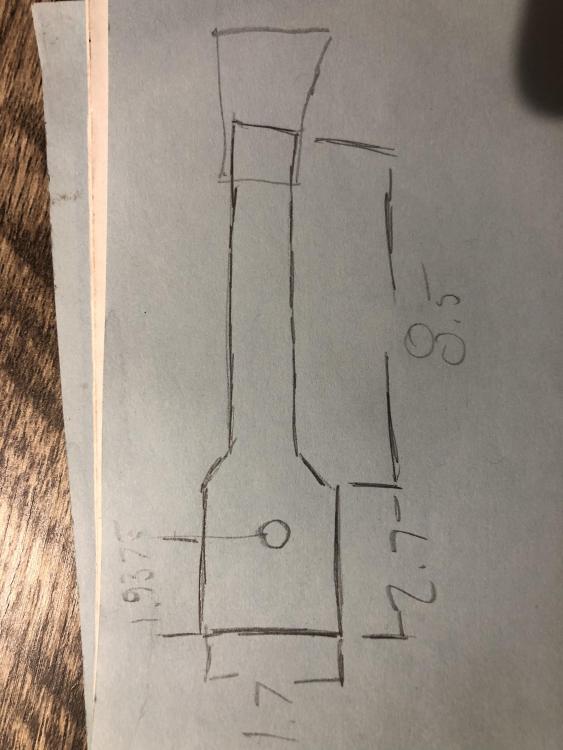

here’s some quick measurements of the 1” burner

so with the small mig tip it should be ok?or should I trim the tube back

this might be tricky since the gas tube is tack welded at either end, some careful cutting and grinding

now back to original issue of excess flames, will creating a proper neutral flame take care of this issue, or am I fighting a reducing flame and too small

-

Mikey for the mig tip, the gas tube that’s in there is only .400” dia stainless tube, the threads on a mig tip (on my welder at least) are .29” long. I don’t see this working to well without cutting out that tube and replacing it with a bigger one.

another question, I looked though the burner to forge thread and was wondering if this forge is simply too small for 2 1” burners, I saw 350cuin was kinda the golden rule for 3/4” burners

-

I have a friend looking into machining some nozzles, should I look into making these forced air? What’s my next step

-

That video is rather outdated but as you can tell from my experience the flame is maxed out at reducing, will any amount of nozzle rework be able to save this?

-

Side note I was sent this video by devil forge of how to tune their burners.

-

Ok so with the little time I had today I think I made progress? Really not sure.

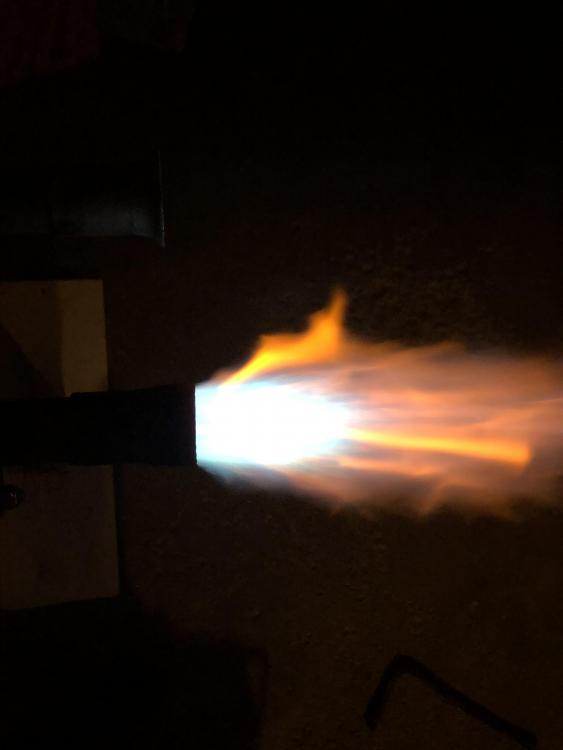

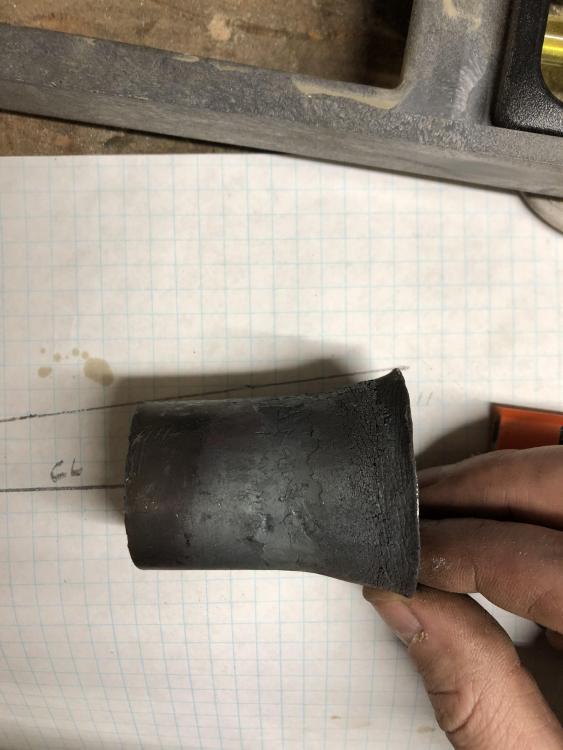

I did contact the manufacturer, they said these burners need to run at 14-17psi and the choke should be about 8mm open.... clearly that last part is wrong.So the nozzle is at just under 1.75” ID at the large end, the taper is over about 1.5” long and starting at 1.3”

The first burner pic is the reshaped nozzle with choke wide open and the second is the stock nozzle run at manufacturer specs

-

I’m going to try reshaping the cone some more tonight, my anvil has a stout horn so it’s kinda tricky

for the 1:12 ratio is that 1” increase over 12” for radius or diameter my sketch there is 1” increase over 12” on the radius

-

Frosty thanks alot

sorry this whole thing has become frustrating and I’m normally a very good problem solver but this is like a foreign language to me for some reason

-

Is this just bad forge design with the burners on top? Like I said earlier when I ran it without insulation around the burner the nozzles got red hot in under a minute, the flame almost comes out hits the bottom ceramic plate and shoots either right back or out the doors

-

-

-

-

5 minutes ago, Irondragon ForgeClay Works said:

It doesn't with my single burner forge while it is running. Some burners are designed to run with secondary air. A reducing flame needs more air or less fuel. How about a picture of the inside of the forge.

I will try this out tomorrow and post some more pics

-

Mikey I’m a little confused now, wouldn’t a reducing flame be more controlled from the choke (limiting air) than from the nozzle?

how does the nozzle control how much oxygen is being combusted?

-

Mikey,

thanks, is what I have referred to as a loose flame? That lighter blue should be more cone shaped correct?

-

-

21 minutes ago, Mikey98118 said:

Than you have other problems with the burners; you need to address them, first; that will probably take a while, and you will need more input from others who have those same burners, and have gone through the same problem.

I don’t think heat escaping and coming up the sides is a burner issue, heat rises and the heat is going to escape through any opening

there’s also a problem sometimes where the back burner (left in pics) will flutter

-

2 minutes ago, Mikey98118 said:

No; I'm referring the the fiber insulation crammed between the burner's mixing tubes and the burner openings in the forge shell. If those were perfectly constructed Mikey burners, that would be okay. Most burners NEED some secondary air, which the flame will induce, unless the opening has been blocked off.

With those open heat would come up the sides of the burners

-

1 hour ago, Welshj said:

I'm a forced air burner owner... but looking at both those pics- it looks as if the chokes are relatively closed off. They regulate the air flow into the burner. Tried opening them all the way up?

So even when I open them there’s lot much change. Maybe even a little more flame

20 minutes ago, Mikey98118 said:Not to mention that all secondary air is also closed off; it looks like someone worked overtime to create a problem.

if your referring to the firebrick doors, there’s not much difference with them off, they really help stop the flame from going straight up

i I’ll get a pic with both these changes and have it up soon

Here’s chokes fully open and no doors

-

Hello all, new here and looking for some help, a friend and I built a dual burner Venturi propane forge. We are having a problem no matter how low of psi we are getting a ton of excess blue flame.

here’s some specs

approximately 680cuin

inside is lined with 2” of mat with rigidizer and refractory

dual devil forge burners

20lb propane tank with regulator(kept in warm water)

each end has about a 8”x4” opening with firebrick as doors

in the two pics the regulator is at 5psi and 10psi, with the chokes open about 3/16”

All advice appreciated

Venturi forge with excess blue flame

in Gas Forges

Posted

Mike, the forge body started as a old small water tank

so I modified it to be only one burner with the modified cone also the burner is at and angle now, the flame is much better and there’s some swirl now

but there is still about 5in of flame coming out. This thing can simply not get enough air

in my tinkering I tried adding one air via a rigged up pressure regulator and airline, and wow what a difference that flame got much hotter with a strong blue color and no more blowing out the side!

so I talked to devil forge and their Venturi burners and forced air burners are essentially the same body with a modified inlet side. So this weekend I will be tinkering with compressed air as well as a small blower I have laying around that I need a rheostat for speed control.

I’ll report back after some more tinkering and update with a bunch of pictures of where things currently stand and with air modification