-

Posts

32 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by slanwar

-

-

I have the bucket and the shovel but I thought maybe they had anything else that would help moving the coals and open the door, I don’t think they used leather gloves 100 years ago to open the door

, anyway this was the best thing I bought years ago, I use wood to start then 1 bucket of coal and lasts the entire day with my shop getting 70’s F.

, anyway this was the best thing I bought years ago, I use wood to start then 1 bucket of coal and lasts the entire day with my shop getting 70’s F.

Actually I was trying to get an excuse to forge something.

-

-

My "garage" has wood floor as well I built as a shop ages ago before I was playing with fire but my propane and coal forge stay outside and I use when is not raining or snowing, the problem is the cold because the pieces cool too fast but I try to do all the working inside the shop (I have a 1900 coal stove inside) like grinding and any wood work.

-

I had to try the blower at full force

-

The flame was that high because I use wood/charcoal to start the fire I use anthracite and I need to start the fire with wood or charcoal but soon anthracite lights up and the wood/charcoal burns out then is like the last picture. The blower is attached to a 4" pipe separated from the main air pipe 6" in a T construction.

-

-

On 10/12/2019 at 10:09 PM, SFC Snuffy said:

Not *in* the shop, per se, but I picked up some hickory 4x4s today with which I intend to make a stand for my

Where you buy hickory from? Can’t find anywhere in NJ, I made a viking axe and I end up using oak for the handle

-

I saw a few in PA but that was the first one here in New Jersey and I reported to the state.

-

-

I'm sure my pump (is a computer blower, DataVac duster) will overheat if I leave on low for too long but I bought a blower which I'm still waiting to be delivered which I should be able to use the variable speed control.

-

I bought a variable speed adjuster from amazon and works really good, cuts the speed from a full blow down to 50%

-

I did that and that was a big difference, now I don't have any problems to start a fire using charcoal and coal, the only problem is my forge is outside and I can't see the heat color and so far I melted a few metal pieces.

-

20 hours ago, dhughes said:

It's 3/4", and thanks, I'll experiment with larger tips.

The tube is 8" long. I did start with a 6" tube, but invariably the heat from the forge would conduct up to the burner nozzle and it would ignite in the Tee chamber, sputtering unless the regulator was turned way up. The longer tube I have found solves this unless the forge has been running for a long time (hours) and then I can wet the burner intermittently to cool it off.

The air regulator mechanism is something I wanted just in case it fixed the problem. Typically I keep it all the way open now, as fiddling with it doesn't improve much.

I could stick a 1/2" tube on there give it a shot too, if you think that's more appropriate. Thankfully that hardware is just a few dollars!

Heh, I'm beginning to appreciate the thought of a coal forge more and more. But I feel there's hope for this gas forge, since lots of folks seem to have more success.

I have a propane forge I built with 2 burners and will take a lot of time to get some metals yellow but others - rebar

for example only orange, so I built a coal forge and I learned to not take phone calls when heating metal....

for example only orange, so I built a coal forge and I learned to not take phone calls when heating metal....

-

I welded a plate on a .........harbor freight anvil

-

That was the reason I built a coal forge because even if I use charcoal I'm able to get the metal yellow.

-

For some reason when I post pictures using my phone they are sideways

-

-

Thanks I will take a look, today I tried the anthracite and my blower must be too strong because I broke off a piece of metal soon I hammered (too hot) plus I had trouble to get closer because the heat and all this outside with a nice temperature of 58F, my blower is for computers but is so strong I use to clean the floor of my garage.

-

Closest one is in New Holland about 1:45 minutes away, I may go there today.

-

I was burning wood to start.... anthracite

, i’m in south Jersey and Im lucky tractor supply carries coal, can’t find other coal even in Philadelphia

, i’m in south Jersey and Im lucky tractor supply carries coal, can’t find other coal even in Philadelphia

-

-

41 minutes ago, ThomasPowers said:

"Be wary of strong drink. It can make you shoot at tax collectors...and miss!"

That's a good one.

That's a good one.

-

Ok I did what Steven said and after looking for some pictures I welded 3/4 high rim, the only problem I had was.....no gas and too many beers, the mig's tank was empty but worked fine after a few beers (I didn't realize until my brother-in-law told me the welds look weird

). Can't wait until coal covers all that.

). Can't wait until coal covers all that.

-

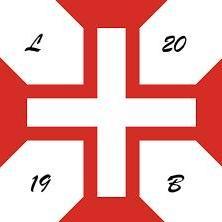

Tool for a coal stove

in Shop Tips n' Tricks

Posted

This stove has the shaker with the handle and I use only when I have the tube inside (left on the picture), I would fill the tube with coal and use the handle to turn the shaker around, that's an overkill for my shop and I used only a few times when the temperatures were really low. I though they may had some special tool for that kind of stove because the top can be used as a stove and we need to remove the top which is hot and then is a plate where I would think they would put the pots on top.