NateS

-

Posts

17 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by NateS

-

-

-

Irondragon. Thank you!

-

-

DanR no worries!

Mikey98118, I made a crude tapered form on a wood lathe. Glued it to a piece of pipe and covered in duct tape. Not sure yet of it was effective enough.

-

Thanks DanR,

The tubes are just forms for a small taper, i will recess the burners.

-

-

-

It does seem large. I have the cut offs i can weld back in. I followed Wayne Coes plan. The opening i have both firebrick and some of the insulation board that i thought about putting kast o lite face. Decisions.

-

-

-

It may be an arm and hammer. Their is a distinctive 1.8 where some of the weights were located under the logo. I am wanting to get the parts to make a burner/forge. Do you still all recommend Fosty's T burner for a noob? I plan on making an oval-ish small forge, perlite/waterglass/aluminum oxide refractory.... unless you all recommend the ceramic fiber.

-

Hey Im happy I got a deal for once. Guy even gave me a couple hardie tool, hammer and tongs. Now I just need to get me a forge built. The rosebud needs to retire.

-

Amish gentleman wants 900 dollars. I figured it was worth it. The one i got is about 175# for 1/3 the price. It would still look cool in my shop. If only I knew what i was doing!

-

Dogblazer thank you.

Chris- I appreciate it. I have not checked rebound with a ball bearing as i do not have one. I did a quick test with a small hammer and it seemed to do well but was concerned hitting the face cold may damage it. It rings loud, slighlty less behind the hardy/hardie. I feel the deal was fair/ in favor of myself. I was minutes away from picking up a 300 pound trenton before the gentleman contacted me.

-

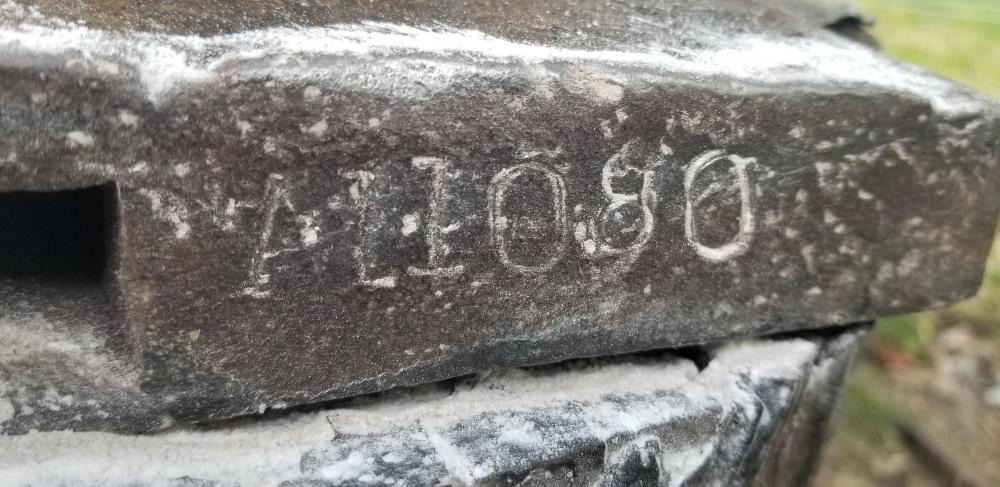

I purchased an anvil last night from a local knife maker. I thought it was a no name anvil. I was getting some of the crud off and found some numbers. On the left front foot a Z is found. On the front right foot the numbers A 110.80 are found. 173#. I looked on the bottom of the forging and it appears to have an Hourglass recess. Could this be a Hay Budden? Also I want to clean/ degrease and remove the paint. Do you suggest i round the chips on the shoulders or just leave it be. Any info is appreciated. Thanks. Nate

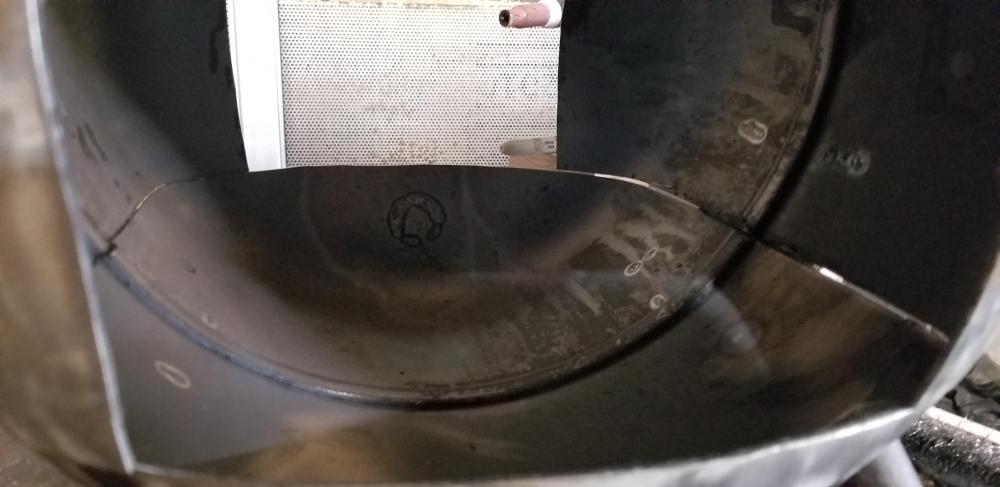

Please critique my forge

in Gas Forges

Posted

DanR- it seemed to have a swirl effect in the forge.... im just happy it worked at this point. My jets are a tapped a little off. I haven't calculated the cubic inches, I will do this weekend. I am glad I put on an idle circuit. I will order the light firebrick and put in a proper shelf.

Mikey- I was surprised how quick it heated up, my expectations we exceeded. It was nice to put a hammer to some steel. It has been years.

I appreciate your guys' input. Ill put the metrikote on this weekend and hopefully make a few hooks or firepit tools.