BackwoodsBeast

-

Posts

12 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by BackwoodsBeast

-

-

I appreciate all the responses, thanks guys. And unfortunately I'm not able to spark test, considering I'm still fresh into this without any power tools. But once I get a little free time, I'll quench a few pieces and figure out what gets the best results.

And yes, the idea was to use it for blades later on, once I get better at this. I just like getting info ahead of time.

-

-

Thanks for clearing that up guys. This community is great.

-

-

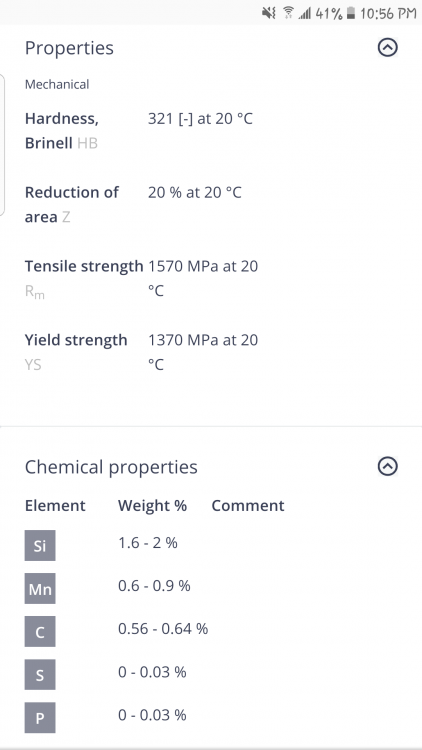

First of all, I'm new here, so I apologize in advance if I'm posting in the wrong section. But I've seen a lot of (guesses) thrown out there about what type of steel these are made of, so I found a list of the properties. Now I'm not familiar in this area, so I'll just let someone else answer that. But here's a screenshot of it.

What did you do in the shop today?

in Blacksmithing, General Discussion

Posted

Yesterday was quite a learning experience. I made my 2nd blade, and love the way it turned out. This was my first heat treat as well, so I followed instructions I've read on here (for W-2). Did 2 thermal cycles, soaked for 5mins and quenched in parks 50. My heart sank when I heard some cracking, but luckily it was just the clay (I went for a hamon). I had gotten a slight warp in the tang because I only quenched the blade, so that was a mistake not to be repeated. I managed to get it out by clamping it to a piece of angle iron during the temper.

After grinding and hand sanding up to 3000 grit, I did close to 10 etches, each about 1-2mins, wiping it down with windex each time to get a deep etch. Now it looks even better than I had hoped. And I honestly don't think I've ever learned so much in one day. And after all of this was done, I proceeded to chop a 2x4 to test my heat treat. And to my surprise, the edge held up as if I didn't even hit anything.