-

Posts

57 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Bean07

-

-

OK im tight when spending in many ways lol thats whats great being a boilermaker all my time to save $$$$$$ haha well here goes ive been very coy on how and about my air supply! I left my mobile at work yesterday and was going to post this yesterday, I bought and use a blower/vac, a cheap one,, I could of gone out and bought a valve but thought it still required an air release ie when doing the kindling etc. folks here may laugh but this works sweet as and cost me just my time and using my welder etc.

-

G,day sly it,s like most things in life like Glenn said with more experiance you get more akin to doing things in a better productive safe order as explained by yourself too, I did a few months working between the two blast furnaces at BHP Whyalla Over 1460C and saw a few guys pass out,we was also working under the top roof bent over ( 5' roof height ) 6 stories up inbetween the two furnaces, we were aloud to walk down every 15 minutes a long gantry/walkway a small platform near the peak with a great view across the gulf. 4 decades as a boilermaker ive work on some very hot jobs too,got to say aswell I dont mind working my guts out too, im enjoying reading up on many posts ?topics here,I love learning from this great Forum, well lets say in a few short weeks ( for me) I have made a wicked coal forge already. cheers Sly

-

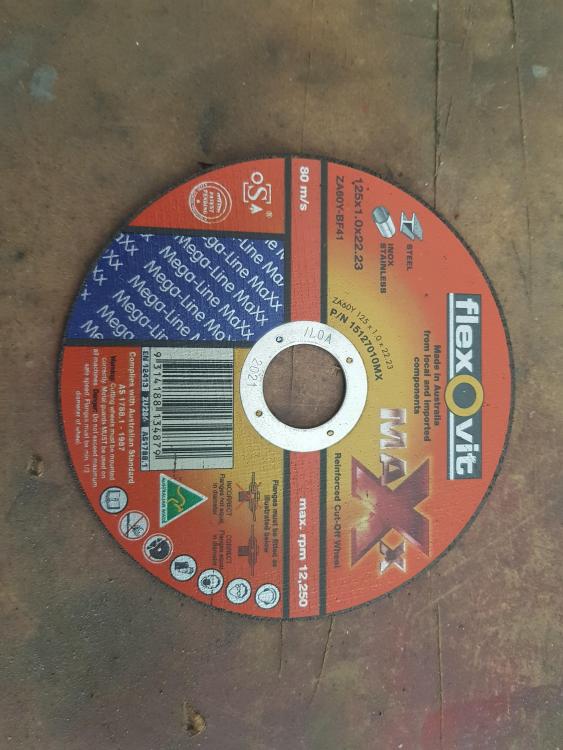

Yes so true Marc1 ! Off topic I luv paying for these! These.oh ceramic is awesome for ripping off welds and flushing

-

-

I hear what your saying Marc1,but for the young it could save from a stuff up, at 23 I sunk a 9" disc at work in my knee, years later a 5" disc in my left forearm, but ive been in the trade since 78.

-

Okay food for thought Marc1 appreciated too! my wife wants me to leave it as! lol I would sooner buy a few better ones like you mentioned,but ive made tools for work boiler making, their still in good use after 35 years, but im keen to start out modifying them if required at the time, You have hit the nail on the head now because good tools is what I need now thanks alot mate.

-

I love my 9" most only come with soft start in OZZ anymore, plus now with a big clumsy D handle , not many engineering shops use them now, thats rubbish IMO, I don,t use it often now but cutting the 12 mm firebox plates is one example, ive got three 5" that get most use in my shed, I really wanted to praise a zip disk though ( 1mm cutting disc ) It is not often when I praise bang fer buck about many items I use, but after using a five inch grinder cutting quite a few 12 mm plates , I used 1 of these only to make the firebox reducer! Best Zip Disc out!

-

Cheers swedefiddle

-

Yes Frosty sometimes photos do more to bring a very dangerous topic up my friend!

-

Thanks Frosty !! the price was right lol

-

-

-

10 hours ago, Sly said:

As Glenn said, Stay fed when using a charcoal forge.

Oh yes that is true! cant beat a great steak ! and water with a nice cold beer to wash it down .

11 hours ago, Glenn said:put on some tunes in the background. May I suggest the following:

https://www.youtube.com/watch?v=IQywghOO1mc and https://www.youtube.com/watch?v=-EJrSIJi-E0

Make your time at the forge fun, and enjoy the ride.

Yes Glenn I like to have music playing every time im in my shed, (Make your time at the forge fun, and enjoy the ride.) pardon the pun ,heres one for that haha

-

1: yes very good!

2:Outstanding!

3: scarily in a way!

4: yes have a great adjustment with the air feed!

Finished with that final touch on the front. Glenn ive been a boiley over forty years! Doing Pressure Vessel making, building mobile cranes designing quite a few jobs, worked with 8 massive propane heaters to straighten the rear of massive dump trucks,waste ind etc. but ive got to say so far in this new journey for me this Coal forge ! I am really impressed with how well it performs.

-

On 1/9/2019 at 1:39 AM, Glenn said:

Modify your fire shape and size to fit the project at hand. It will also save fuel.

If you find a shape fire you like, weld up a base plate (that fits the bottom of the grate) to the extension you like and keep it on hand for when it is needed. Makes it easy to clean out the fire pot, insert the modifier, fill the remainder with ash etc, and light a fire. When finished just remove the modifier. Think of it as your new rose bud. (grin)

Took good advice all was fantastic today MKIII Test im happy as !

-

What size is your chimney diameter?;; the chimney is 11"

Please let us know how it turns out. :: No worries ,im back at work from Monday so I wont be doing as much as ive been doing,so it will be steady as she goes from now on.Thanks again for your wisdom Glenn.

-

Just installed the fake grass they luv it in there ( Ragdolls)

-

-

Cheers yet again Glenn ! ok a lower front wall to suck the exhaust better it sounds more logical looking at this first photo, I did want to know how high to lift it but that is also said! Im curious as xxxx second photo how hot did it get roughly, I worked five years in BHP and watched the big digital Dial say when the steel was formed ! and from memory it is 1430 C, 2606 F, so what do these get too? Also ive completed my version of your fuel saver idea cheers for that too. second to last pic she cleans up so easy thanks again for what im learning.

-

xxxx in the northern suburbs ( South Australia ) one would be lucky to score 2 acres for $300,000 !!! just land!

-

-

-

G,day im at Gawler South Just commissioned my very first coal fired Forge yesterday, im new to Blacksmithing ,but 40 years into boilermaking, I finished off my forge yesterday, after Glenns advice I made a new base grate and this was my second go last night

link removed as it will not load.

-

.thumb.jpg.0c14189f0e17e093efa3d2a37b1030b4.jpg)

First solid fuel forge fab.

in Solid Fuel Forges

Posted

I never drank so much water and had a few beers too, we started early (6am) in the steel fabrication workshop due to every day in my first week back being over 40c,that was also the same last week on holidays too, I also put on average about 4-6hrs in my shed working on my forge after a hot work day, it gets tougher when we get older ( 56 ) but I have to say theirs no one in our workshop that works as hard as ive always done,I have a two litre bottle of cold water in my shed bar fridge that I refill daily ATM.as always it is great looking at all things from others prospective s cheers again Shabumi, Sly and all here.