-

Posts

22 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Casapa

-

-

There are alot of variables to take into account, I havent installed a forge chimney, but Ive installed a fair few gas fires and solid fuel fires/stoves.

A warm chimney is what you are aiming for. IF you have a single skin 12" pipe, chances are a 8" twin wall will work just as well. No calculations on that atm.

So if you live in a cold climate with a 12" single stack, thats going to cool down pretty quickly.

I plan on using 6" inch twin wall flue pipe on my forge as a base size, this is adequate for approx 20-30kw solid fuel(68,000-102,000 btu). I havent calculated what my potential forge heat ouptut will be yet, still on planning side, unless anyone knows a rough figure. But a large multi fuel stove gives off approx 12kw

Chimneys/forges need adequate combustion air. So good ventilation is required to complete a good working chimney.

Extractor fans also play a huge part on the performance of chimneys. If you are running a large extract fan in your shop it will be having a negative effect of the efficiency of your chimney.

This is just a few thoughts, fly by post, it may help.

-

Great video, you're helping me out alot.

-

I can only please one person a day. Today is not your day. Tomorrow doesn't look good either.

-

Depends what you need and how much you want. Theres lots of click and pay stores online, The metal Store has easy web site and lenghts from 1.5m, but delivery costs hurt on small orders. Most seem to charge approx £ 2 a KG, and offer free cutting. Ebay has some small quantities. But if you could grab a lift from a friend, you can pop in your local seel supplier and grab off cuts, around £1 a kg.

-

I think fridge pipes comes sealed and cleaner inside, nominal sizes may be different along with wall thickness, which may cause problems with compression or flaired fittings.

You could always buy a mini bender, they cost approx £15 in Uk for cheap versions, maybe less, so not so expensive.

Thats fuel lines for an Oil boiler I recently installed.

-

Only bad point about the video is his carbon monoxide detector positioning.

https://www.hetas.co.uk/wp-content/mediauploads/COconsumer220118DIGITAL.pdf

-

http://www.beautifuliron.com/chimneys.htm .There you go

Theres other pages on that site, once there click the top link to main site.

-

I found this video which might interest some, has a nice link too.

-

Nice tool, will remember this.:)

This guy makes it look easy.

-

All Fossil fuels produce CO, so choosing gas or coal doesnt give you a safer option.

I get bulletins sent to me quite often regarding current standards. Heres a couple that may interest you in your plans.

SAFETY BULLETIN REGARDING CHARCOAL GRILL OVENS

There are potential dangers from barbecues and in particular, the fact that coals that appear to be dead can still emit dangerous carbon monoxide fumes.

The HSE have made us aware of two related incidents involving catering establishments where after cooking had finished for the day, unattended charcoal grill ovens caused a build-up of carbon monoxide which subsequently percolated into neighbouring premises and resulted in two cases of carbon monoxide poisoning.

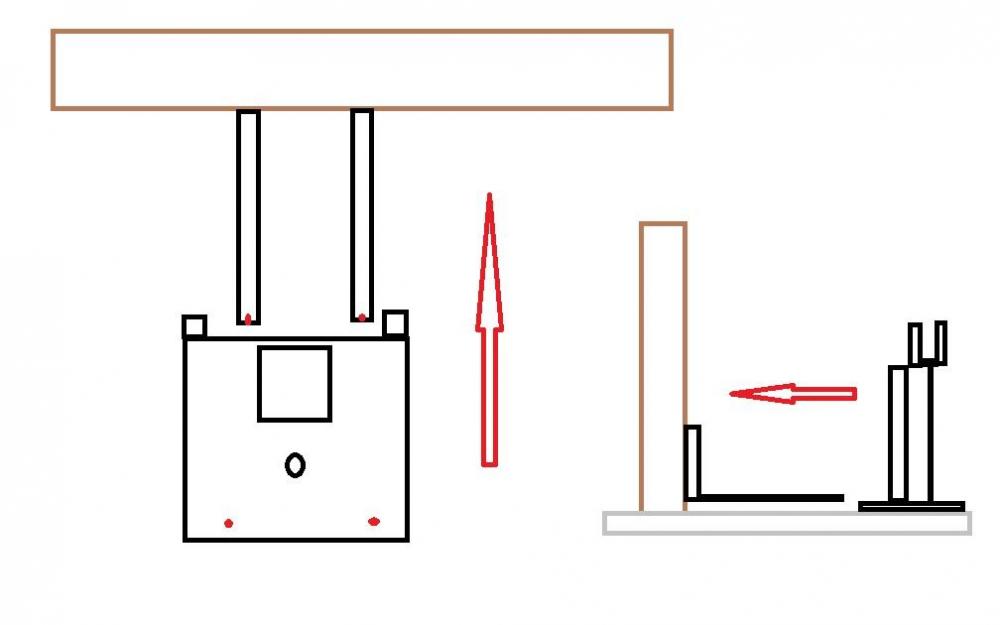

This type of charcoal oven should ideally be flued directly to the outside via a purpose built chimney in accordance with Approved Document J of the Building Regulations. However, we are aware that in some cases, the grill is simply positioned beneath a commercial kitchen extractor as shown in the picture.

There are two major risks that need to be guarded against when using this arrangement:

- Lack of proper maintenance can lead to blockage or failure of the extraction system – it is important to follow exactly the manufacturer’s maintenance schedule.

- Because dangerous products of combustion (including CO) will still be emitted after cooking finishes for the day, the extraction system must be kept working for as long as is necessary to prevent a build-up of poisonous fumes.

The oven manufacturer’s instructions for installation, maintenance and use should always be carefully followed.

Heres a link to current solid fuel appliance guidlines, might be useful.

http://www.hse.gov.uk/pubns/cais26.pdf

-

18 hours ago, jlpservicesinc said:

Lead is not a good idea as it will give and smear with each hammer stroke.. IE extrude.. I've seen it..Had a feeling about this one, thanks for sharing youve seen it happen.

Also thanks for all replies, gives me a few ideas.

-

2 hours ago, ThomasPowers said:

You should be able to fit the wood to the base. Hint turn the anvil upside down and move the base as you fit it.

Ha, slapshead. Thanks.

Ive seen the posts on caulk, but this has a good half inch twist, caulk is fine, but has limitations on depth.

Yeah natural slate looks nice, Ill grab a clear day pic for you if interested Branding Iron, though having Oak battens and copper nails was hard , even with a pilot hole I needed someone with a Timber prop under the striking point for each nail, added quite a few hours to roof.

Buried 3 feet in the ground.

-

Hi finally got round to getting my first Anvil sorted. Im planning to build a wood base, have some Oak 6" x 6" section from the structure I built below.

However the feet are a little twisted. Its a wrought Iron Anvil.

Many moons ago I have wiped lead joints in plumbing and thought I may load the anvil base with sticks (lead/tin mix) then file flat. I think I have a suitable flux that will work. Basically Im gonna solder a slab of lead and then make it flat. I could router out the wood base, but as my Anvil is a bit of a beast and Im guessing 450lb + so lifting is a problem, though I could hire a engine lift for a spell. The lead is one idea Im thinking of, unless anyone tells me its a horific idea

Its only had its first brushing, and no markings so far, can only see what looks like a H on the front.

Thanks for your time.

-

Please dont be unaware of the dangers. Fossil fuels can and do kill. Ive been in the heating industry for over 30 years and Im the third generation of heating engineers in my family and unfortuanelty have seen fatal results of badly installed appliances. Forges are no differnt , whether gas or solid fuel. Please research the effects of fossil fuel exhaust gases. Even using a forge with an untested chimney is dangerous if you dont have the correct set up and draught.

As a small test, position a table in the place where you intend to use your forge. Pop into Plumb centre or any plumbers merchants and buy a pack of smoke pellets ( used to test appliance flues). Light one in your garage and watch where the smoke goes, will give you a good indication of the dangers you will be putting yourself in, and members of your family. There is never a "less of a worry". Its either Right or Wrong.

Stay Safe.

-

You could make some L shaped brackets bolted to the small walls you have, always easier to fill and hide mortar holes in walls than in nice floors. You could always make them hinged brackets so the fold up out the way. Could relocate without too much hassle, you would have to possible weld some counter sunk bolts to vice plate and have cut outs on brackets so it will slide in and bolt up. Just an idea.

-

-

Thanks for the replies, nice info.!

-

Anyone tried or even seen these burners? Just browsed into it and it sparked curiosty and the prices seem ok.

Apoloigies if posted before.

Also found a build here

-

I wouldnt get too hung up on trying to analyize your own work space, as the CO , oxygen and CO2 levels will constantly change as you opens doors , time you have you forge on for etc. So taking one reading may give you a false sense of security, I have one due to my work, so its easy for me to check. Your main aim is to install a CO detector in the correct place and have adequate ventilation at all times, your forge will use the availible oxygen in a small space and the longer it burns the less will be availble, resulting in incomplete combustion and CO levels rising. Im in UK and use a Fluse gas Analysizer.

Flue Gas Analyser

-

On 12/10/2018 at 7:45 PM, Mikey98118 said:

But the second flame will produce a little carbon monoxide in its exhaust, so it will need to be run with a fan-blown exhaust system. Why is a little CO considered a big deal? Because it builds up in your red blood cells, and takes about three months to be flushed. Thus, a minor exposure to CO can be quite dangerous when it's ongoing.

Hi , Ive been reading the site for a while, just dabbling into the art currently and designing my first Forge. Mikey and Frosty and this site have been a big help. I noticed Mikey's comment and thought I would throw this out to you guys, most will know , but some may not. CO is a killer , but CO2 is as well. Ventilation is key. Im kinda fortunate that Ill be testing my working forge and area with a Gas analysizer for combustion products (Gas Safe Engineer). But I see quite a few photos of new guys burners in garages with the door closed. Stay Safe guys. Sorry if it sounds condescending as a new member, not meant that way.

CO2

250-350ppm Normal background concentration in outdoor ambient air 350-1,000ppm Concentrations typical of occupied indoor spaces with good air exchange 1,000-2,000ppm Complaints of drowsiness and poor air. 2,000-5,000 ppm Headaches, sleepiness and stagnant, stale, stuffy air. Poor concentration, loss of attention, increased heart rate and slight nausea may also be present. 5,000 Workplace exposure limit (as 8-hour TWA) in most jurisdictions. >40,000 ppm Exposure may lead to serious oxygen deprivation resulting in permanent brain damage, coma, even death. CO

9 ppm CO Max prolonged exposure (ASHRAE standard) 35 ppm CO Max exposure for 8 hour work day (OSHA) 800 ppm CO Death within 2 to 3 hours 12,800 ppm CO Death within 1 to 3 minutes -

If you can't make it perfect, make it adjustable.

That will do, its Rudolf Nearenough.

Propane forge

in Gas Forges

Posted

Just to add to Frosty's post.

LPG is flammable and heavier than air so that it will settle and may accumulate in low spots such drains and basements. Here it could present a fire or explosion or suffocation hazard.