Ouchmysciatica

-

Posts

19 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Ouchmysciatica

-

-

Fort Dodge. I built Frostys, T Burner xxxx near exact.The only difference is I added the shut off 1/2" valve and 1/2" to 1/8" reducer. And that's because I dont have the money for all the rest. I had those on hand.

-

OH!! I SEE NOW. The reason why the burners only look similar is the store where I live does not carry alot of the materials and parts the burners require. So i have to get more creative. Which is only fun when it works lmao.

-

Hmm.. well, the flame is not very stable. Mike I'm not fully sure as to your instructions. You're right tho, it is a nipple welded to the outer forge body. The curious part I'm having trouble visualizing is this..

2 hours ago, MotoMike said:you could then probably fit a flare on the mixing tube made from one inch black pipe.

The coupling part was curious too, why not just drill n tap the nipple welded to the body?

-

-

Wowser!! Yeah.. I just pained this wall, gotta make sure it dries. Lol From what I've read, as soon as one wood layer begins to ash, you then add another layer of wood. Until the cone is full.

Seemed like it was a rather solid idea as far as the Japanese went? But exactly where would this average Joe get a metal cone 60X30X16??

-

Has anyone tried the kontiki method of making charcoal? By the way I Have no clue as to where this goes, feel free to move/delete

-

I didn't have bar oil so I shot for att fluid. Now it just hums beautifully. Still sideways tho. Lol, I'm not sure where to put it vertically.

-

Didn't know they needed any honestly, thanks again Irondragon.

-

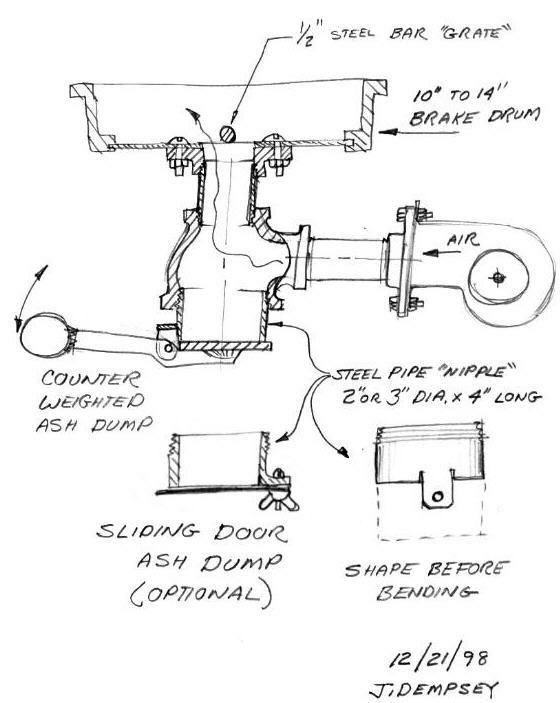

I did not think about a brake drum!!

Although, I had the rim available. I dont have a larger brake drum available.

Thank you guys soo much this helps alot. Glad I came here! I did post an issue I was having with the blower so far this is where I am with the forge...

I'm looking into making it into a side blast now lol

-

Well I know you guys aren't fans... ha fans... of youtube but I couldn't get a better description for you all...

-

-

I'm looking at jlpservices pics like, ooo look at those tongs wonder what they are for, ooo! Look at that one what's that!? oh hey!! Lol

Haha sorry I'm new!

-

-

Thanks guys, slowin this waaaaay down

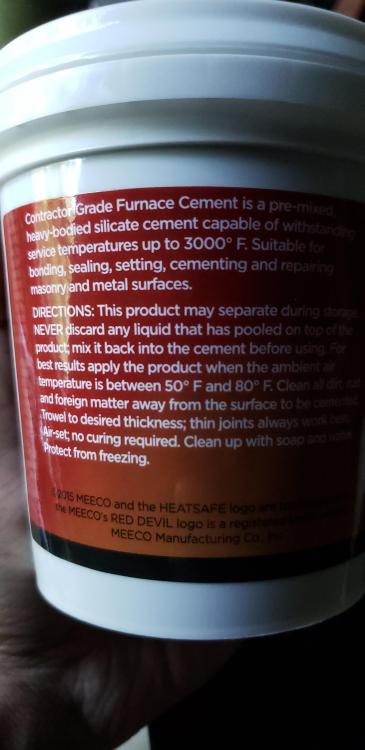

Well, now the hunt begins for proper material. Refractory and rigidizer I havent used the cement because I didnt have decent rigidizer so, stepping back til I find some.

-

The castable refractory cement is dry and seems really good. It's just a "Add water" mix. Plenty there and I did some more reading here picked up on the flooring thank you frosty I added more inswool. Bad part is tho I'm broke, can't do anything more with the burner so as of now it's what I got, wish I would've picked up a 1 1/12 -3/4 bell reducer, instead of the bushing crap. ( reading up on Burners 101) on the hunt for fumed silica.

-

I did, I thought maybe I could use the furnace cement as "rigidizer" but as I went through 6 other forums I'm glad I didn't proceed. Not to say I couldn't have found the same information here, I just wasn't able to get a straight answer, or I'm too dumb to notice or work this forum lol.

Also I got some cat litter good natural claylump kitty litter. Not sure what to do with that yet lmfao. The digitizer is where I'm stuck, I know it's not absolutely necessary as to I planned to coat the entire inside with the refractory cement, but I would like to be sure that fiber isn't floating around as I'm huffing and puffing swinging a hammer!

-

Oh boy here we go, my very first forge was from a #10 can from baked beans. Filled it with plaster of paris and sand and used a mapgas mix and torch to fire. #gross. Next was the 5 gallon air tank i filled with ceramic wool, attempted to seal it with refractory cement MRD. Not bad but was too opened and couldn't get it to temperature. Well hopefully the title is all I need.

MRD is what I have in my area up here in xxxxx xxxx xxxxx humid Iowa.

The wool is i cant remember the brand but i remember it 8# 1 inch that i wrapped 4x. Yup 4inch thick.

Good ol` 20# propane tank

Burner got complicated. I can't screw straight, xxx xxx xxxxx but aside from that this one seems sufficient.

Let me know what yall think, I desperately want some input, tell me if It sucks, really, no joke.

The plan is to fill the bottom with castable refractory cement as a firebrick. I'm not sure if this is going to be or not but to me it made sence at the moment. I was thinking to seal the wool with the furnace cement.

Third times the charm?? PIC HEAVY

in Gas Forges

Posted

Ok.. here's a few videos with the burner again. I have a few changes in mind for the forge mounting the burner is the major change but this is where it is now.