-

Posts

19 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by GMURDOCH

-

-

18 minutes ago, Charles R. Stevens said:

There is some thought that the hot gas should circulate in the same direction that your toilet water does. As to validity I can’t say.

one should consider adding some insulation to your set up, unless your casting engine blocks you have a lot of volume to heat.

It's not finished man lol.

Next week I'm picking up a ceramic blanket and castable refractory

-

I have a question for you. I was talking to a guy and he tells me that the position of the burner should be in the clockwise direction as I am in Toronto Ontario Canada and being in the northern hemisphere. Does anyone or can anyone confirm the validity of this claim? Thanks in advance guys...

-

Thanks for that Glen...

-

April 17th 6-9pm at 208 Gerrard st.east Toronto

Hope to see some of you there...

Just thought I'd throw this out there

-

Love the avatar. Does this mean a Hyrule sword is in the future?

-

21 hours ago, Daswulf said:

I think you got some that it will be a long, expensive and tedious project.

Have you sourced the aluminum and titanium yet? Any thought as to what parts will be what metal?

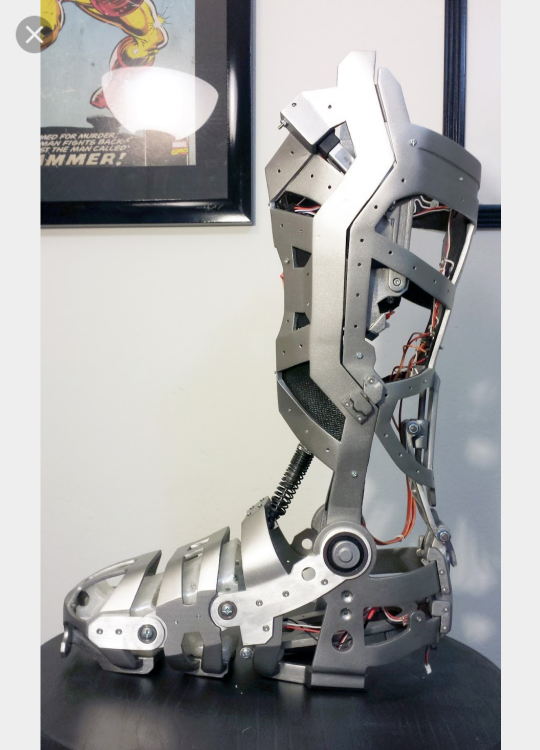

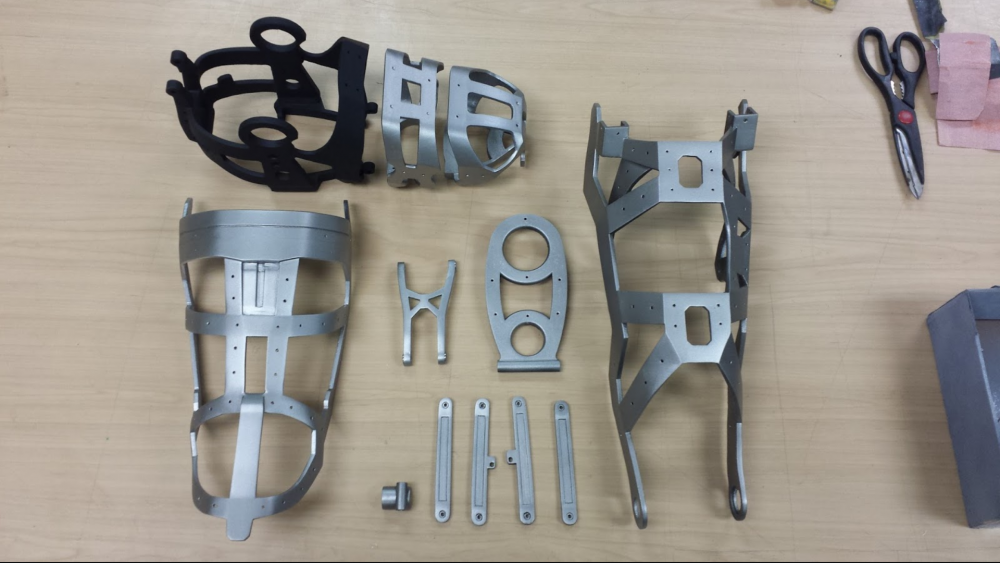

Joints will be made of steel, for the most part. Metal Supermarket and simular suppliers for the aluminum the titanium I am yet to find a supplier in my area. This pic for example is awesome but the foot moves back and forth but really it needs to pivot side to side as well. Took me a while but I figured out how to make that happen. My boot will be simular but modified to my needs...

I failed to mention that last week i placed an ad in kijiji to see if i can join a metal casting group. To learn and develope my skills as I am just starting out. A fella textd me today saying that he was interested in starting a group and he owns a foundry business. I had prior obligations today with my family but I told him that I would definitely be contacting him tomorrow.

-

That's awesome JHCC, Thanks for posting.

Tools have been expensive as buying the wrong tools really takes a toll.

Finding a place to store my tools is a chore lol. I have tools on the balcony in the apartment, at work and in the truck.

I have been searching for a metal hobby lathe but the cost right now is not affordable right now.

-

I have bought some aluminum from Metal Supermarket, some from a scrap yard.

Titanium I have some 2.5"- 3 " wide 20" lengths 2, 3mm thick. The titanium I'm going to use for accent pieces.

Still searching for more via bike parts. In another life I was a cyclist, owning over 50 bikes over the yrs.

Mountain bikes, BMX bikes for clarification...

The pic is titanium that I picked up from a former employer.

Need a good cleaning...

-

It would appear I posted this incorrectly, I meant for this to be in the criticisms category.

Well anyhow, I'd love some thoughts on the this.

Good or bad...

-

This link is a video of a jeweller bench I built to help along the way.

My apartment is small so work space is a nightmare. So a collapsible work bench was a great solution.

Poor quality video but you get the idea...

I posted a link and it didn't work...

content://com.samsung.android.email.attachmentprovider/1/46/RAW

-

I will start from the beginning.

In 2009 I saw Marvels Iron-man, I loved it. Pt2 followed and ibwas hooked.

I couldn't but help wonder if it was at all possible to make one. No not with all the gadgets, weapons and flight capabilities, that silly. So I went to Google and found a Prop-building forum. This place was amazing for anyone who is a fan. So I did a ton of reading on the builds.

Primarily they are made of either EVA foam mats, cardstock paper coated in resin for strengthening. Both methods I have tried using a pepakura program. The foam doesn't last as my cat has shown me, the cardstock resin is messy with a lot of chemicals. Both of which I made an upper torso. They both were quite cumbersome to move in, Robbie the robot kinda thing.

3D printing is also a medium that builders use. But the cost and the understanding is beyond me.

It had been suggested that I should go with a Kevlar build. Again chemicals, I live in a very small apartment with limited space. I can do some stuff at work but i don't want to go that route as the boss would be passed lol.

OCD kicks into high gear. I can't stop wanting to build this, so then I realize what about metal?

Now bear with me here, I am not rich nor am I an engineer. To be quite hones, I left school at 15. Now before you jump ship, here me out.

As a kid you accept what's thrown at you. Raised on Farwell aka welfare, alcoolic parents mixed with teenage ignorance and misunderstanding of the world around. So accepting my place and my limitations wasn't that difficult.

I was a janitor at a pawnbroker, custmer asks me question. Sales rep interrupts to say that I know nothing. Of course I was passed and out of spite I became a jeweller selling wares. Did that for 10 yrs finishing at an upscale boutique in Toronto's upscale neighborhood. Now I had a taste of success. Back to the build, so with a jewelry background I figure metal will be best for my armour. So I go into Research and Development mode. Educating myself in metal forming, casting, mathing. Reading books on mechanical movement, kinetic movement, robotics, engineering, casting & arduino: programmale micro processors. YouTube has been my friend. Forums like this one has really paved the way as well. So a metal armour still sounds tuff. What if I built an exoskeletal armour with plates that attach. Now I'm on to something, I can replace damaged parts or upgrade my armour as I see fit.

I am going to build an exoskeletal armour based on the War-Machine but redesigned boasting a full range of motion with lights sounds and servo motors. This will be in aluminum, steel and titanium.

Some say weight is going to be an issue, but evenly distributed I should be good for a short while. I mean I'm not going on a hike in the mountains with it. I will post some pics of some of my research. This will be slow as I work a lot of hours and I am still buying tools for this project. I look forward to your opinions and criticisms. Thanks for getting to the end lol...

-

I bought this kiln off a minister for $20.00 Canadian, that's about as good as a deal as any lol. It came with the electronics removed. I will be picking up some castable refractory, ceramic blanket. The burner I made from black gas pipe whih I will use as a forced air propane method. Need to get myself a regulator gauge, and construct a crucible. I would buy one but I am only melting aluminum with this. But hey if I can get a deal on a good crucible then I'll go that route as well, safety first...

-

-

I belong to quite a few forums, for different disciplines. I actually attended a couple of metal forming meets, working the English wheel and such. I eventually got an English wheel, so now I can do it from home or work. Along with my beater bag & my block, just picked up a hammer with multiple dies. I call it Mjölnir.

-

8 minutes ago, ThomasPowers said:

If you can chrome thermo forming plastic you will get con-worthy suits a lot faster!

You can chrome plastic, but it's very expensive.

As far as con worthy, it started out that way and evolved from there. Metal is the only way for me.

-

1 hour ago, Daswulf said:

Welcome to the madness. Through some research here you will find that you don't need all the fancy tools to do some forging.

I don't really know what WarMachine is. It it the game that came up with a quick google search? Is this going to be full size or a miniature? Details can help us help you.

Looks like you have your work in research cut out for you either way with all you are wanting to learn.

Any tips on Removing chrome plating? There are many tools and things that are chrome plated and not safe to forge or weld and if there is a way to remove that chrome it would open up a lot of possibilities.

We use reverse polarity or simply just hydrochloric acid to remove chrome.

War-Machine is a character from the Marvel Cinematic Universe

This is a wearable armour. The pic is the original War-Machine, mine will be different.

-

1 hour ago, ausfire said:

Welcome to the forum. As you said, plenty of reading here.

That's a pretty impressive piece of engineering in your picture there.

Funny thing, just seeing your name and location. I have just been watching Murdoch Mysteries on TV - based in Toronto, Canada!

Yannik Bisson the actor who plays Murdoch, I went to school with him. Really nice fella.

1 hour ago, PVF Al said:Welcome. Your work is very clean and exact. I like it. If you can find a local forge group near you, you will be surprised at the amount, and range of knowledge that can be accessed. Al

The boot pic is not mine. That is a 3D printed piece by a guy named Christianson...

-

Hi all

Brand spanking new.

I am from Toronto, Ontario Canada

I am a hard chrome electroplater and a hobbyist. My hobby has lead me here.

I am building an exoskeletal armour based on the War-Machine and skills that I need to further my goal of completing my build has drawn me to this place. I am currently constructing a casting furnace but I am also considering a forge. So I have some reading ahead of me. Love to learn about this craft so here we go. Just a sample pic of what I'm looking to do. I guess I should be more informative.

I am a huge fan of the Iron-man series, that being said I want to make my own. I got into prop-building and through trial and error I've realized making a metal armour is the way to go. Research and Development has been huge for me. I have no experience in any skills really beforehand.

I've had no tools with exception to jewelry tools. So between learning and buying it has been a chore.

I'm studying metalcasting, metal forming, machining, welding, electronics. Just to start.

I am building an exoskeletal armour based on the War-Machine but redesigned, boasting a full range of motion with lights sounds and servo motors. Made of steel, aluminum and titanium. That's it, in a nut shell.

Murdoch's 1st furnace

in Smelting, Melting, Foundry, and Casting

Posted

Does anyone have a recipe for making castable refractory?