Joey smith

-

Posts

43 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Joey smith

-

-

Thank you your to kind. I’ve got a lot of learning to do so don’t you go anywhere mikey ! I appreciate all the help. More questions will follow.

-

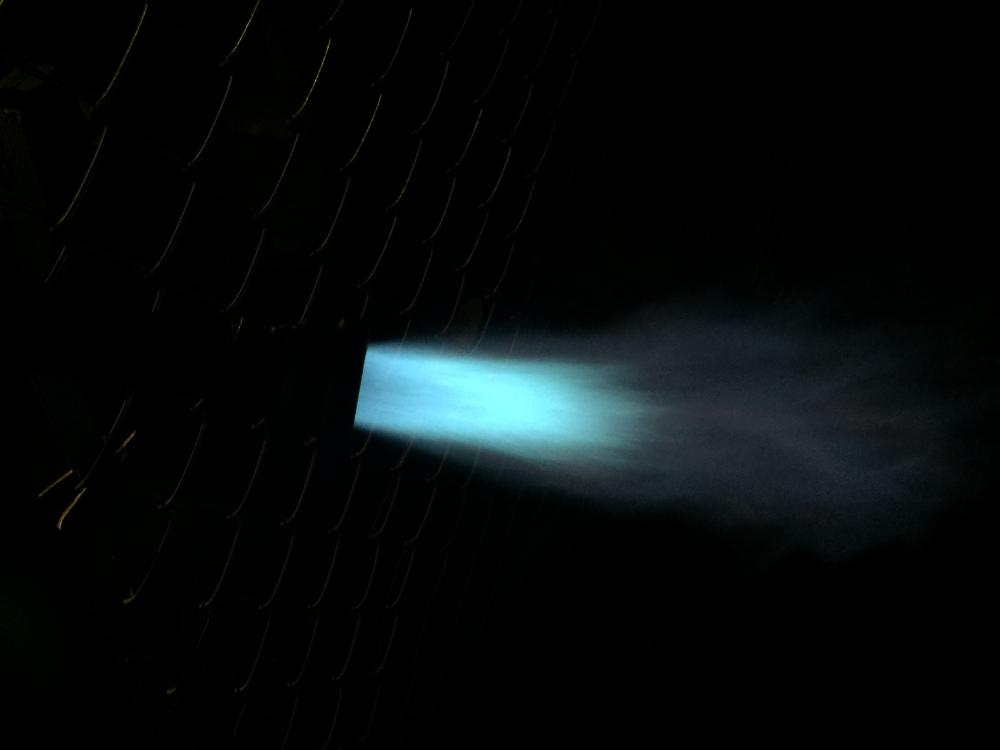

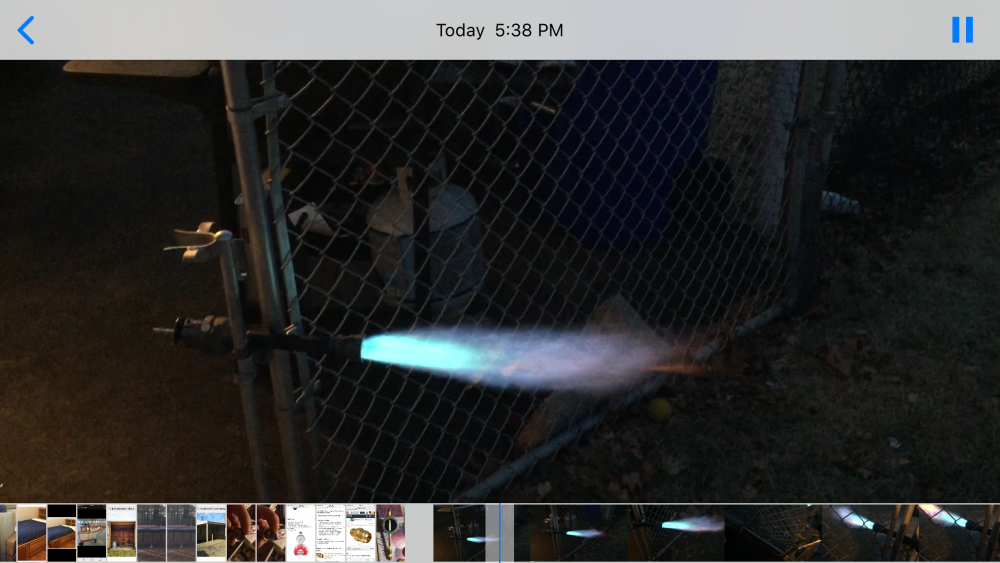

Im Using .035 mig tip used some gas tape to tighten up the fit . Still need some set screws to hold directly down the tube .1.5 to .75 inch bell on top bottom is .75 to 1 inch i left the threads in the bottom or flame side. Should I remove these? And is .035 enough or should I open it up to a larger orifice? The flame seems better with the tape but still id like better. Please advise oh great burner gods! P.S. new photos attached.

-

Thank you. I will!

-

-

thank you.I will do as told. I fight with my inner know it all who’s not so bright.

-

Ok thank you!

-

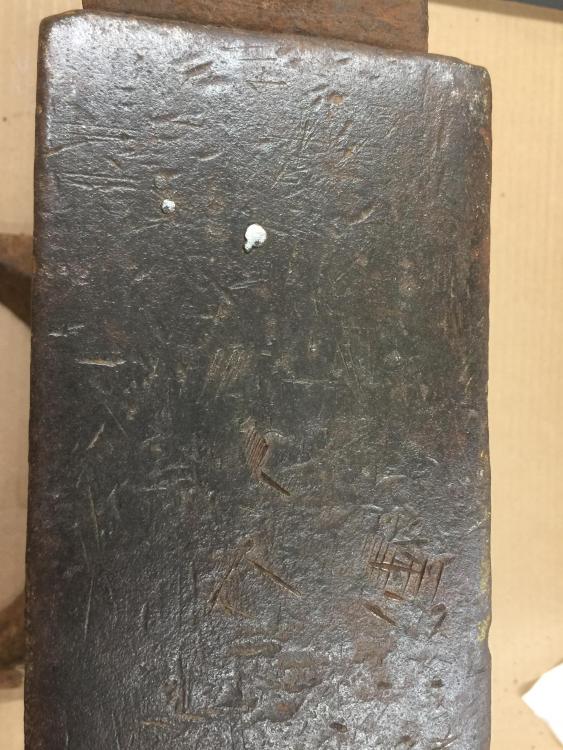

Would you recommend doing something about the weld?i filed a chunk a little bit and bought a cup brush for rust removal.

Thank you I.D I would appreciate a schooling on it.

-

The pritchel looks original although im not an expert. The top I wire brushed and it looks like a chisel smith and a welder owned it at some point tips on removing the weld would be great and if i should do any other work. Also I weighed it its 174.7 so it is 1.2.10. Nice edges though.

I also ran a file on it it skates right off is this a good cheap Rockwell test?

-

Thank you i will get some closer pics tomorrow and post asap . I appreciate all the feedback.

-

Thank you ID! The rebound with ball bearing seems a little short but no buzzing and nice ring all around. 65% ish rebound

-

I purchased this I hill anvil and wondering if anyone has advice on derusting and should i do any restoration on it . I will be using it hopefully by early spring in New England. I’ve seen many opinions on this wonderful site about cleaning and restoration not sure which would best suit me. I have access to many advanced machines and people with experience not in anvils but machining.Thank you in advance for any advice. I will post more closeups of face when i can.

He sold it as a 110 i think its 1.2.10 which if I’m correct is 178. I’ll be weighing it tomorrow

-

I just watched YouTube video from 2016 I am going to get out there !

-

I’m just starting out.when and where is quadstate it sounds like a hoot maybe I’ll actually have some practical knowledge by then. Although highly unlikely!

-

Thank you Thomas.

I’m over it

-

I have an opportunity to buy this hammer what should i offer? I may have offended him with the 20 dollar original offer! Being new to this my etiquette may not be up to snuff.

Its in Massachusetts

-

My first burner

in Gas Forges

Posted

It looks good but I’m am amateur!