Joey smith

-

Posts

43 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Joey smith

-

-

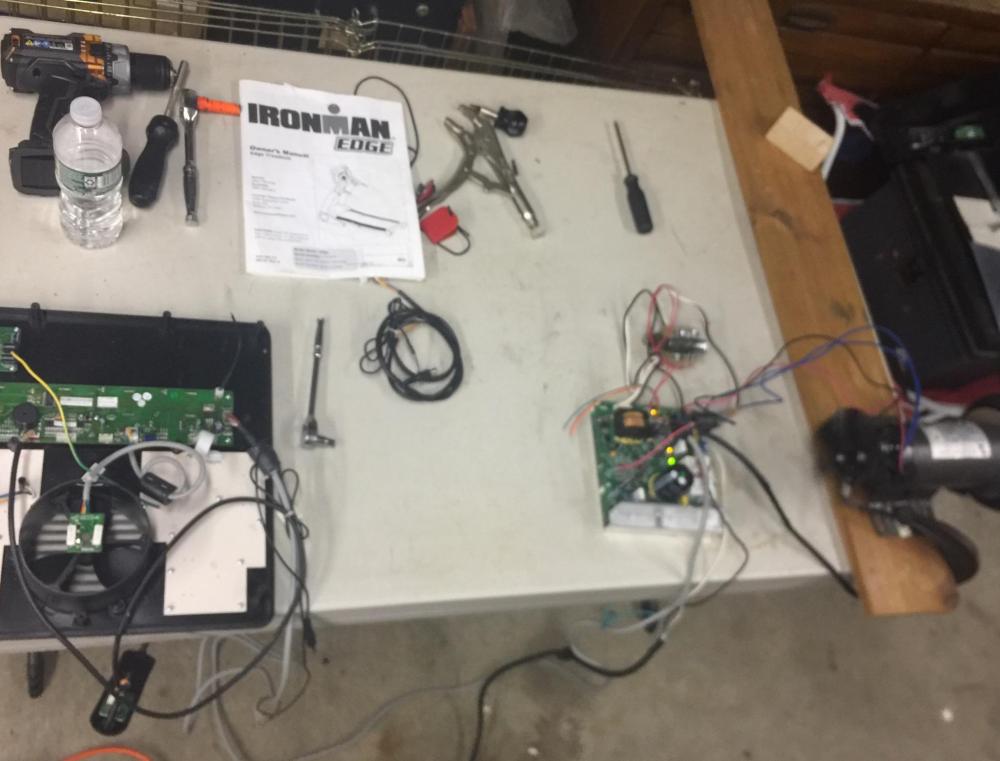

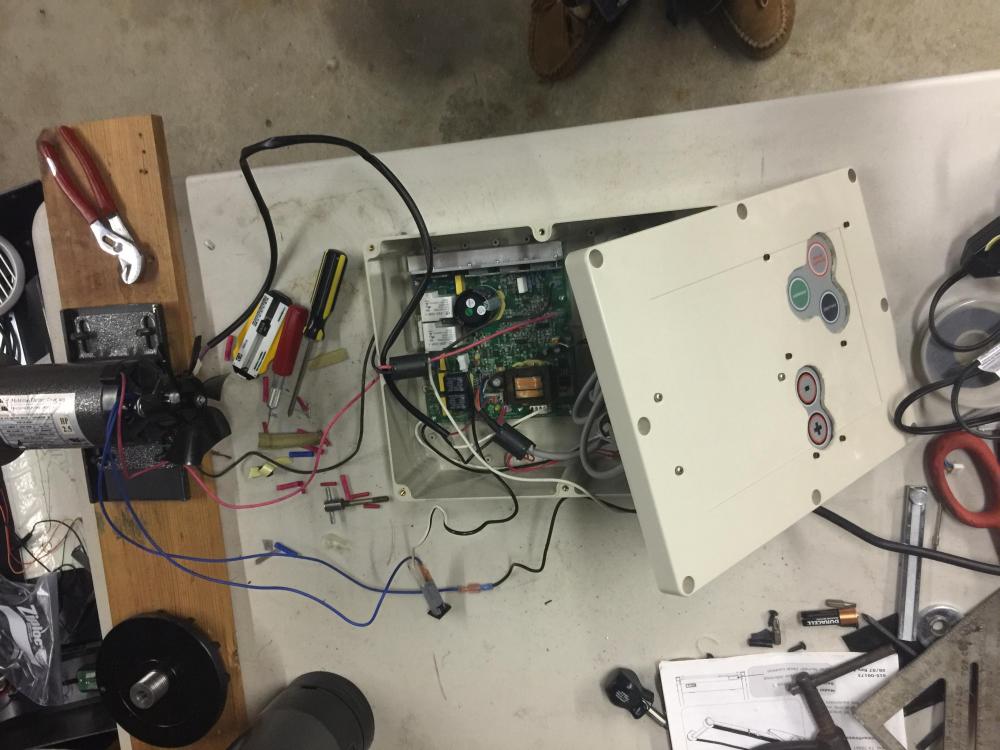

Thank you Latticino, I've run it up to scary speeds with no vibration. I will build a good vented enclosure for the motor, I did not know it could or would be that sensitive! I’m also going to make a replaceable motor mount plate for easy swap when this motor fails. It may be Swiss cheese in a couple of years if I don’t. I’m also running into a speed feedback issue that shuts me down at higher speeds and I’m trying to eliminate the tach on it but it’s proving to be a fun challenge. If there is a solution anyone knows of? I’d be happy to hear? Thank you again.

-

Thank you guys. Yes I could reverse it but the drive wheel is a welded on 6 lb hunk of spinning chaos and the thread does not protrude to add a nylock nut. Loctite 554 might work but a chance In safety is a chance I’m not willing to take. I’ll send a mach up pic of the grinder when the platten and arm is done. Me good not explain very things well if when do! It’s one of my many curses.

Thank you again.

-

I am building a grinder with a treadmill motor and I’m wondering if there’s any reason I can’t put the motor on the right side and run the wheels on the right side as well and just move the motor farther right?plus I’m wondering why or if I have to put a static brush on the belt ? I mached it up to the left in image . Also is there any good reason to have the belt on the right side?

-

Sorry mod34! My sincerest apologizes!!!!!

-

Sorry Aus!

I know people who are NOT allergic to sulfa based drugs who have used it for years without negative side effects. And I’ve known many people who are now in the ground due to alternative pain medication. Sorry it’s a little personal, if I’ve been out of line I apologize.

And I hope you resolve your elbow pain!

-

Thank you for the information I Truly appreciate it Ausfire. I have no doubt of it’s levels of danger hence the disclaimer. It is a wonderful topical analgesic for joint and tissue pain relief if used properly! 1 death occurred due to misuse [political content removed].

That being said it can and is purchased and used otc all over the us but doctors here can be reprimanded for even responding positively about the use of it. I’ve asked my long time trusted Physician!

Thank you again.

-

Good thing I’m not in Australia!

Mate!

-

I use DMSO dimethyl sulfoxide although if used improperly it can carry surface contamination from your skins surface into your blood stream. It is an amazing natural chemical when used properly on joint or muscle pain ! DISCLAIMER : I am not responsible nor have I created or profit from it’s usage read about this before using it!!!!!!!!!!!!

-

At this point I’ll be proud of hot metal hitterly Thank you Frosterino.

I’ll try a quick grind on a couple before attempt 6. Thank you Thomas!

-

Free scrap ends. I picked up about 200 pieces 1”x 3/8” x 8”

free is my favorite price especially for practice pieces!

-

Thank you Frostman.The scarfed joint was my fifth attempt Ugh . I’m going to try again when this rain ends as my smithy has no walls yet . New England is a weather machine but AK I couldn’t imagine not having walls and a heater and a plow and a shovel and a fur coat!!!!!!!

-

I’m using 1018 cold rolled spotless clean, hitting with 2.2 lb and probably too hard. And fluxed when dull red waiting for some dancing flux then within 5 seconds striking. I believe it’s an environmental thing in my forge I’m watching with ir goggles and my burner sputters and im watching the scale form. Also I scarfed a joint and still no sticky sticky ! Flux is borax . Also I think im a little nervous and not wanting my forge to get destroyed. So I’ve decided to gather more info which you gentlemen have aided in , continuing to forge projects and check out a mentor as Thomas has suggested. I believe you’re all spot on more experience less fear and some one on one training. Thank you guys again.

-

Thank you guys maybe I’ll go to theABANA

-

Yes I’ve applied a large quantity of flux probably getting the attention of entities not wanted

-

My daughter suggested Thor!

-

I have now entered the magical world of forge welding with —200% results! I own a Matthewson metal smith forge with a 3/4-1” additional kast-o-lite floor which seems to reach the temperature produced by a star! Still to no avail I cannot forge weld. Using borax, mild to mild and near lemon yellow color. I did not scarf the weld perhaps that is the magical solution? Or the choke needs closing to produce reducing environment ? When I do this the forge seems to be pulsing and not getting hot enough. I’ve also prayed to Oden and the all father. Please any help would be wonderful! I’ll include pictures . Also thought you might like the hex driver I forgot to move.

-

-

Thank you!

-

Thank you Frosty! Game on!

-

I did find Lou L’s article , consolidated info from the more experienced people on ifi . Seems simple if this works.

-

I’m wondering if there are any full length videos of the curing process for kast o lite 30 as I want to re-coat my forge with it . I have ten lbs and I’m hearing and reading so many different ways from let it sit at ambient for a couple weeks before firing to curing the next day! I have limited ability to track or slowly raise temperature as the instructions state and do not want to waste any refractory if it’s avoidable. I’m in New England and it’s humid! Please help I can follow concise instructions if they do not include temp tracking and special equipment!

-

Thank you Frosty!

-

Thank you guys, I have some machinist friends maybe I’ll have a lathe turn a 4140 or 6 for me.

-

I’ve been hammering this nightmare out with a power hammer named Joe. I’m wondering what drift to buy or make and from what material it should be? It’s going to be a war hammer / Tomahawk if all goes according to plan and my arm doesn’t fall off . Any help with drift choice would be greatly appreciated. around 1”-1.25” seems the standard but materials from ductile iron to 4140 tool steel are suggested by YouTube University alumni.

Grinder build questions

in Grinders, Sanders, etc

Posted

Progress