watermelon

-

Posts

15 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by watermelon

-

-

aha sorry i didnt realise you were referring to a sticky. i have looked at that before but it seems to conflict with other info in the forum.

for instance you suggest 3/4 over the tyuerre, but the table suggests 5", which is a totally diffrent scale.

i think my fan and tyuerre are a bit oversized, i plan to dump some of the air. will having a reduction nozzle make much diffrence?

cheers Charles

-

my tuyere is 45mm and my fuel is charcole.

do you have a photo of your trench? finding it bit hard to visualise.

i cant see the article?

thanks for your help

-

i am planning to make knifes, axes hand tools, stuff like that. not going to be heating really big stock.

-

-

i have been looking around the forum but im finding it hard to find exact details for the dimensions. i want a sideblast.

what is a good size for the fire bowl?

how far from the bottom of the bowl should the tuyere protrude? how much space above the tuyere to the surface?

how big should i make top surface? obviosly bigger will hold more fuel, but what is a practical size?

cheers!

-

i think i have found a section of drain pipe, that is cast iron to use for a tuyere.

is cast iron a good material for a tuyere? how can i test it?

it has been outside for some time, it has some paint and rust on it. if i clean it up should i protect the surface or let it gently rust?

-

On 16/12/2017 at 11:54 PM, timgunn1962 said:

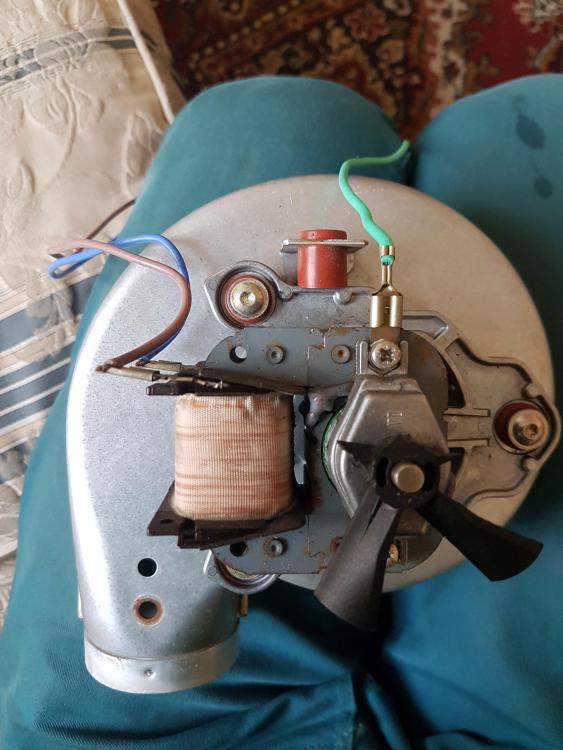

It's a shaded-pole motor and they tend to run hot. You'll probably need to sort out the broken fan on the motor shaft if you are intending to run it for very long.

I don't know what was on the front of the casing originally, but it's a pretty safe bet the inlet was a lot smaller than the big hole that's there now. You'll likely need to close it down to a smaller entry with a cover plate. The outer edge of the impeller is visible and it'll leak out lots of air as it is now.

yeah it is a shame the fan got broken. im hoping it is not going to be a problem, i think it will be ok because it used to be running in an elnclosed box inside the boiler, where there is little air circulation. i will be running it in the open air with more air moving around it. i will test it to see how it does.

i wish i still had the cover plate. i have no idea what size the hole needs to be. i could make somthing out of plastic or ali, but i dont know how to test it other than just feeling the output with my hand.

thanks for all your advice guys! much appreciated.

i have mounted the fan, wired it all up, and tested it. it worked fine.

its all safe with rcd, earthed cable, and insulated crimped spade ends. i want to add a foot switch when i find a suitable one.

an electrician friend down the pub said i can easily fit a speed controller. would this be a dimmer type switch, or a specific "speed controller"?

anyone have a rough idea as to the tyere diameter i should go for? my intuition says just use one the sameish size as the fan output. is there any befenfit to reducing it down?

-

2 hours ago, Marc1 said:

That is a mains blower but designed for a different country not US. Of course I don't know where you are so if you are in UK or Australia you are fine. If you are in Australia, remember that it is illegal to do any electrical work by yourself.

That blower is for a 50 HZ network and in the US you have 60HZ. Generally small motors like that will work on both frequency with some limitations overheating and underperforming, however since you are going the other way, and the speed will be limited by the load, it may work OK on 60HZ.

Of course suggestions to plug it in, is wrong unless you have a 220V 60Hz powerpoint in the house/workshop. No motor wired for 230 will run on 110V and don't even try. You could buy a step up transformer though ... always assuming you are in the US.

Just to clarify, 220V 230V or 240V is more or less the same. 110V 120V is more or less the same. 110v and 220V is not the same.

hi marc, yeah im in the uk, we have 230v 50hz mains here. thanks for the info

-

you guys are getting way to hung up on this. look im even doing the research by asking here.

my issue is whether this motor needs a transformer or if it can just run on mains. i dont have any experience with motors.

if it needs a transformer i will have to go down a diffrent line if enquiry.

if it runs on main its just two connections over an inch apart. where is cross wiring going to happen?

-

i really do understand your concern but i am going to do things safely.

i am going to run it with an RCD, all wires will be soldered, secured, and shrink wrapped. i have some brackets to mount the fan to a log so it wont move around. theres not really any chance of cross wiring. if it works out being useful i would build a housing of some type.

-

i dont really see what there is to be scared of. im not going to touch live parts and all connections will be solid. electriciry is safe as long as you are careful.

-

yeah i searched the serial number which identifies the fan model. sadly not really any info just suppliers.

i also concur that motors of this style i have seen have been wired directly. i dont want to blow the motor trying without knowing.

i have messed around with quite alot of basic electronics and i know how to be safe, but i appreciate the concern. i will probably have to put a housing over the motor if i end up using the fan.

yeah i searched the serial number which identifies the fan model. sadly not really any info just suppliers.

i also concur that motors of this style i have seen have been wired directly. i dont want to blow the motor trying without knowing. 230v 50hz is mains here in the uk, does that mean the motor can be direct wired with no transformer?

i have messed around with quite alot of basic electronics and i know how to be safe, but i appreciate the concern. i will probably have to put a housing over the motor if i end up using the fan.

-

JABOD dimensions

in JABOD - Just A Box Of Dirt

Posted

i really appreciate your input. im english and i was taught in metric at school, so i apologise for getting a bit confused. the way imperial measurments are written and vocalised, i have to consciously think about convert back to something i can undertsand.

i would be tempted to use coal but its not really available here. in my area we have ancient coppice woodland and really good quality charcoal.

im currently making an air gate. im not sure if i can find an end cap as cast iron has been out of use for decades, so im not sure how i can reduce the tuyere down.