Timeswelding

-

Posts

14 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Timeswelding

-

-

I was able to weigh it. It is right at 144 or 145 pounds.

-

Thanks for the info, guys. Any idea of its age?

-

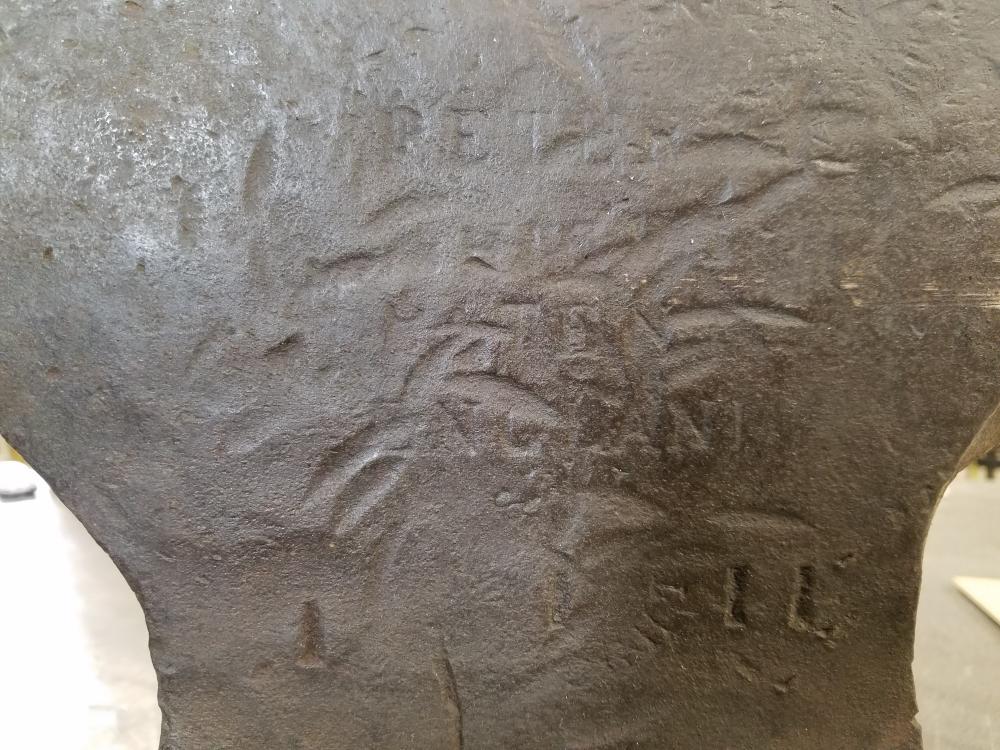

I was wondering if you all could help me identify an date and anvil. We've had this in our shop for at least 25 years. it was a gift from a local farmer who is a close friend. It weighs 145 pounds, rings like a bell and has a rebound of about 85%. On the right side I can make out "Peter" and then a bunch of jibberish (to me) and a "0" or "O" on the lower right side. At the lower front side is "BB". Those are the only markings I have found. Thanks in advance for any information you might be able to share.

Doug.

-

They are a great machine. very versatile and would excel at all of the tasks you mentioned plus countless more.

-

10 hours ago, CMS3900 said:

That's a sweet hammer. One of the best clones I have seen actually. One of these days I would love to get a little pullmax.

Thanks . I really enjoy using it . For a Pullmax we have a P9. Keep in mind that the Pullmax is a fixed stroke reciprocating machine so it really acts nothing like a hammer .

-

Miamisburg , OH . We always welcome fellow tool junkies.

-

Well, that does make me feel better . Indeed it is a very nice tool.

-

On 3/11/2017 at 4:49 PM, njanvilman said:

But even with the chips, cut and obvious use marks, the anvil is till in nice shape.

Everything I told you above is correct. Crossley made, 1965. If you and your Dad use it correctly, this anvil is just barely broken in. It will last many more generations.

I appreciate your info on the age and the history of the company. I'm sure it will out last my dad, me, and probably my nephews . Also, I checked out your Facebook page on the museum . So much great info and pictures .

On 3/11/2017 at 6:46 PM, VaughnT said:Getting rid of the cut will be the most problematic and I don't recommend even trying to radius that much.

All told, an excellent piece of kit that will last another hundred years or more. If I was selling it, I wouldn't even hesitate to charge $4/lb for the thing. I'd probably start out at $6/lb and let someone talk me down.

I would never consider trying to remove the cut via an edge radius . That would be a ton of material removal. If I knew the alloy and heat treatment of the top plate I may be able to come up with an acceptable weld procedure for filling the cut. I'm just not sure if I want to risk it. As for the price, I guess I didn't do too bad I paid $3 per pound. I have always had the mindset that , when paying for a high end tool, I have never overpaid. I have, however, paid what they are not yet worth. Meaning that eventually they will be worth what I paid and I'll have them to enjoy in the meantime.

-

The guy I bought it from dressed that corner. I had considered continuing that radius the entire length of the right side. It's pretty large. Probably a 3/16" - 7/32" radius. It would clean up nearly everything but the cut mark. The left side is in much better condition , so I may sand a 3/32" or so radius on it. Any thoughts on that plan?

-

I got some more pictures of the anvil this morning. Now it's time to build a stand. Due to the dreaded Emerald Ash Borer beetle, we have an abundance of ash logs available , so ash it is. Also, I checked the rebound with a 1 1/4" ball bearing and tape measure and it appears to be between 85 and 90%. I don't think we can ask for any better than that.

4 hours ago, VaughnT said:So great to see a Fisher in such immaculate condition. It looks like it has never seen a hammer strike.

You can buy brand new anvils that are in similar condition, so you should value it "as new". Anvils don't depreciate unless you beat them like a redheaded stepchild. And because it's a Fisher anvil, something you can't get any more, that adds to the value. It's not an antique, but it's still a rare thing.

Kind words, but, not so true. My camera angle may have been a bit too flattering for this anvil. While it is in very nice shape, it has seen some abuse.

-

Hi guys. I'm new to the forum. The vast majority of my work is in sheet metal shaping, but we occasionally have to do some forging. Anyhow , I thought you might enjoy seeing our shop-built power hammer . My dad and I finished this machine in 2008. That's Dad in the picture. After the design was nailed down, we had 580 hours in building the machine and machining the dies from S-7. It's designed for sheet metal shaping so it's built far too light for forging and that is why the working height is so high (so you can "sight" the surface of the panel you're shaping). The heaviest marterial I have shaped with it is 1/8" 304 stainless steel, but it'll move 16 ga cold rolled sheet like butter. Since most of the panels we shape are .040" steel, it's more than enough hammer. We built two sets of arms for it but currently have it set up as a single hammer . Anyhow, I hope you like .

-

Njanvilman, thanks for the info. I can post some other views tomorrow . I was under the impression that the later anvils did not have the eagle logo cast onto the side, rather, they used a paper lable. This is why I consult the experts. Would you have any idea of the value of this anvil?

Thanks again .

-

I just bought my father a "new" anvil for his birthday . I was wondering if anyone here could help me determine its age. From what I've read, I assume it's a Fisher because of the eagle emblem cast onto its right side. It has "225" cast onto one of it's front feet. I assume that is it's advertised weight. I weighed it at 230 pounds. "h65" is cast onto the back of it above the feet. There are no other numbers, letters, or symbols appearing on it. It does have mounting lugs with holes in them front and rear. Any info would be much appreciated . Thanks in advance . Doug.

Help Identifying an anvil

in Anvils, Swage Blocks, and Mandrels

Posted

Thanks again for the info, guys. I was just curious as to what exactly it is that we've been using for better than 2 decades. I also need to learn to decipher the weight markings and conversion .