-

Posts

153 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Tzelik Hammar

-

-

That sets my gears spinning. Awesome idea!

-

Randell, I found this among others with a quick google search.

Thanks for googling it, I shouldn't post before bed I guess. Never thought about horses leaving anything but a horseshoe shaped print...

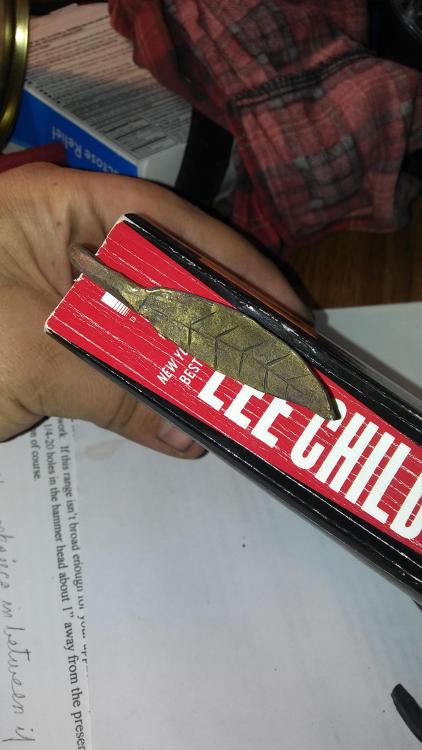

It will be fun to try to figure out how to work that into a bookmark!

Today I made a pretty, comfy, and completely useless BBQ fork. It fits in the hand nicely, its pokey, its forky.... its also soft enough you can bend it with your hand while holding it. Guess I grabbed the wrong 1/4 stock. Anyway, Pictures! (Also worked on more tongs, but no pictures of those because I am not finished.)

-

Beautiful. And symmetry really is strange. Look at people, very few are symmetrical and the ones that are kinda stick out, usually kinda oddly.

-

I'll have to work on paw prints then. What distinguishes horse prints from horse shoes? The lack of groove and holes?

-

Hrmm. Does turning it into sparklers count?

-

Michael: I love em. Best bookmark idea I've ever seen.

Thomas: No, don't have your number and mine would come up as Albuquerque.

-

With beginner hammer and fire control, I think de-refining is appropriate.

-

-

Pm me your address and I'll work it out

A small price to pay for knowledge.

-

I'm loving this exchange of information. It's exactly what I was hoping for! Everyone has a specific idea of what a smith "must" know, and the overlap is interesting.

Please keep it coming!

-

Lol. Appreciate it Frosty. I swear I laid the stuff out, I figured you guys had already taken it

-

Slag, currently working through that series! Just interested in the opinions of "old hands" as it were. The ABANA set is excellently done, but courses and tutorials do not always carry the value of a voice of experience.

-

-carefully lays out sacrifices to the curmudgeons: beer, wrought iron, various shiny objects, coffee and pie-

Ok. Don't eat me for this, but I would like opinions from some of the experienced members.

The question:

What would you, personally, consider the basics of this craft? Maybe 10 things you think every single smith should know how to do consistently. I have read many many threads of things that are marvelous and awe inspiring. I am not asking for links to books or other websites, I am asking personal opinions.

-

Curly bark or shavings sounds right if I'm thinking of the right thing. I know it's what I call pieces that come off when I'm using a draw knife and it produces long thin curly bits.

-

Das, sorry, should have realized you had already thought about it and tested it! I like the table with chain idea.

Gergely, the patterning in those candle holders is beautiful.

-

Good luck Zero!

Das, excellent looking stand, though the feet scream trip hazard (to me) if you have to raise it very high. Did you keep the teeth on them for aesthetics?

-

Thanks, Das and Thom. I was just checking for safety reasons.

That's a neat forge Zero. What are you using for air? Is the thing underneath some sort of blower? Very interesting looking!

-

I'm actually under the edge of a ... Uh. I don't know the word. It's attached to my motorcycle shop, so it has that wall, and a back wall, with other two sides open. The forge sits near the edge for ventilation until I get the back corner cleaned out and can relocate (and build a hood). I use a tarp for the wall on the outer side but it's plastic stuff and I keep hot things away from it. It's just to keep the weather off my coal, sand, and scrap. With fall here I'm working to move the forge in more for warmth.

That actually brings up a question I've been meaning to ask... Is corrugated roofing tin galvanized? It's old stuff, dad built the shop when I was a tot, and I need to know if I have to worry about heat around it. The whole building is just a wood frame with tin over it.

-

-

Good call. My brush stuck to the magnet.

As for the sun, I'm limited in where I can put my forge, so I do small stuff in the morning while it's full sun, more important projects when it's shaded, and go home when the sun hits it again

-

Thanks Frosty! The butcher brush is in my list this month, I watched a video by Joe a week or so ago and realized it wasn't just a wire brush like I've been using!

A drive hook, ok, I'll look up a proper J hook for Wednesday! I hammered it into my cabin wall to hold my keys and ball cap. I tried scrolling out the tip "after" I had curled it, and just failed so I tapered it back out before I destroyed the whole thing. Gotta remember to scroll first.

I've been trying to get the shiny brass finish with a different brush but it doesn't seem to work, does that take a special brush or technique too?

I'm trying to do the basic projects in Simm's and McRaven's books, getting my horse back in front of the cart.

The little axe got cooked pretty hard, I'm practicing small welds (folding instead of upsetting) and it got away from me in the fire. I'm pretty sure the knife is cooked, I quenched and then stuffed it back in the forge still dripping oil... Brain fart. No huge flare-up but it textured it really weird.

Running too hot is something that is taking a while to figure out. I work in full sun and have to try to gauge the color against the coal glow, I put up a piece of sheet metal to give me a contrast but it didn't help much. I'm looking for "nearly orange" most of the time, but by the time I get it into the shade to see it, it's usually a deeper red. Is that sufficient?

... Or my brain checks out while I'm cranking and when I come back it's scorched...

-

Very nice. That is a fine sign.

-

I need to turn my foot pedal like that. I put it the other way and it doesn't hold very well

-

To keep with your theme, but make it easier on the eyes, maybe go with the Anvil and Zelda looking sword, centered vertical on the Anvil, with the nazz square center?

Ideas for Christmas 2017

in Blacksmithing, General Discussion

Posted

I'm planning on very simple pattern welded candy canes. Two or three layers and a lazy twist, hammered round and hooked.