-

Posts

17 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Mihai Cadis

-

-

That might be the case.

-

I will clean it but only Monday I get to do that.

The re-use of top tools is a great idea, thank you!

I am amazed by the size of it. Also by the fact that the face looks like it hasn't seen a lot of work. I would have imagined that a beast like this would have been used a lot in big industrial settings.

-

I will be careful. Thank you!

-

10 hours ago, Glenn said:

Congratulations, you have a monster anvil !! Get it home, clean it up, and apply hot metal and a hammer to the face to make you both happy.

Thank you, sure will!

10 hours ago, pnut said:Good luck with it. I don't think you'll need a bigger anvil than that one unless you start building battle ships

Thanks! No, I won't need a bigger one. This is too big maybe but it was around and I didn't want to miss it

I have no equipment to move it around but I'll manage with a big crowbar and muscle. That's how I got it home. Once on a stump near the forge it won't be moved only rarely

-

The weight is marked on it.

-

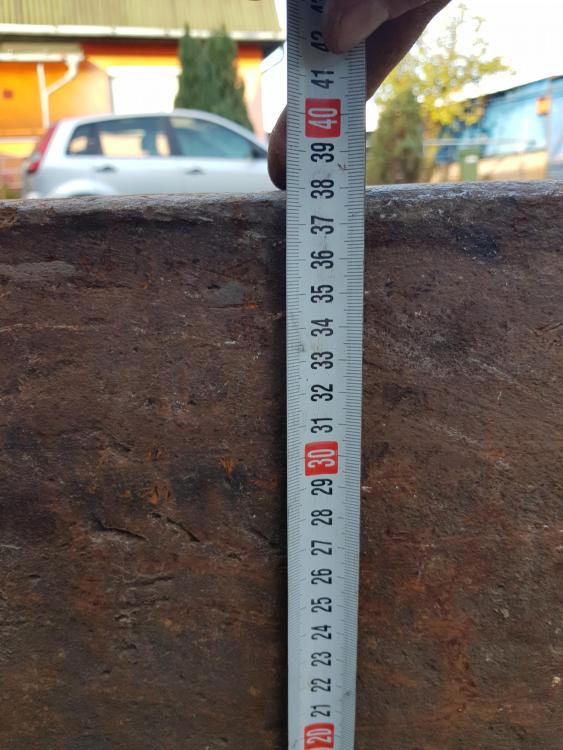

Hi! I just got another anvil and I need some help identifying it. It weights 672 pounds and it's the only marking that it has.

It has two hardie holes, 1 1/2 inch.

Length 42 inches , width almost 7 inches, height 15 inches.

It comes from UK.

Didn't clean it yet but the weight markings are pretty clear and there are no other visible markings on it.Also I'm not sure about the face. Does it have a welded face? It's clearly made of pieces forge welded together since you can see where the weld didn't blend. I left if home since and can't get back for better photos for a few days. Did a rebound test while on the grass with no plank under and the face with rust and it was around 50%. Has some rust since the guy that had it kept it in the rain.

-

It's an Italian power hammer, Maccaferri,50 kg ram. They still make new ones, same principle, a little different look and motor placement. This is an older version.

I've changed the spring, put new ones. The motor is replaced. I only have to make dies and fix the dovetail.

I put a video, hope it uploads

-

I got in touch with one that does that. I'll send the springs and they'll send new back. Hopefully by the end of next week I'll have them.

-

Thanks a lot for the advice! I will start the restoration process and keep the post updated

-

6 hours ago, Latticino said:

Your English is wonderful for someone who has it as a second language.

Thanks! Yes, I was referring to the pulley. I would rather buy a new motor since they are not that expansive here and with a VFD I would get about the same cost. Also with the VFD I will lose power, up to 40% it's what I've read.

If I make the spring from spring steel but won't heat treat it after will it work?

-

So I went and bought the hammer

It has some problems, the major one being the springs. The top one has been welded on both sides. I have to replace that.

One other problem that first I thought was serios was the dovetail on the anvil,but after taking the die out it does seem soo bad. It's fixable in my opinion.

And the last one is the motor. No ideea if it works but not really a concern since it's 3 phase and I will replace it with a single phase. Its a 2 horse power motor.

The ram dovetail is ok. Very very little slop. And if i grab the spring and try to move it back and forth there is some slop but not what I would consider an issue.

Also there are some welds on the thing that the ram goes in. No idea about those.

Some dimensions :

The ram is about 50 cm (20 inch) tall and 13.5 cm (5.3 inch) in diameter.

The Hammer has 150 cm (60 inch) overall height. About 600 (1322 pounds) kg weight

I'll attach some photos. Please give me advice about the anvil dovetail fix and springs. Is it ok if i fill the dovetail gap with welding?

Also forgot to say no cracks, the rest of the parts seem in really good shape. Little little play in the round piece that the motor spins with the belts(sorry that i don't know the name of it, English is my second language)

-

-

When I drift I want to be able to stop at a certain point. Pipe might work. I will try. Thank you!

-

Ok, I understand. I'll make some kiss blocks. Thanks all for your answers!

-

That's what i'm talking about. An adjustable depth stop. They usually have it on the srew, it's a split collar that also has threads. The screw having on the top portion smaller threads on top of the big ones. I could use a block under the ram for a stop but it's really unconvinient and not really adjustable unless you have a lot of blocks in different sizes.

Thanks for the welcome!

-

Hi! I am in need of advice regarding a fly press that has no stop on top of the screw to make it stop at the desired point. Can you please give me an idea on how to solve this?

Will a split collar for hydraulic cylinder put on the screw work? Or will it damage the screw?

Don't know the size of the press but the screw diameter is 60mm (about 2.36 inch).

Anvil identification help

in Anvils, Swage Blocks, and Mandrels

Posted

Cleaned it a little. No other markings found except weight. Rebound is about 60%. Face is in good condition.