Firemn260

Members-

Posts

24 -

Joined

-

Last visited

Profile Information

-

Location

Aberdeen MD

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Yes. Left side on the front of the base

-

-

Wire wheel is as far as I go on any of my anvils. I’m going to give it a good once over this evening and see what I can find.

-

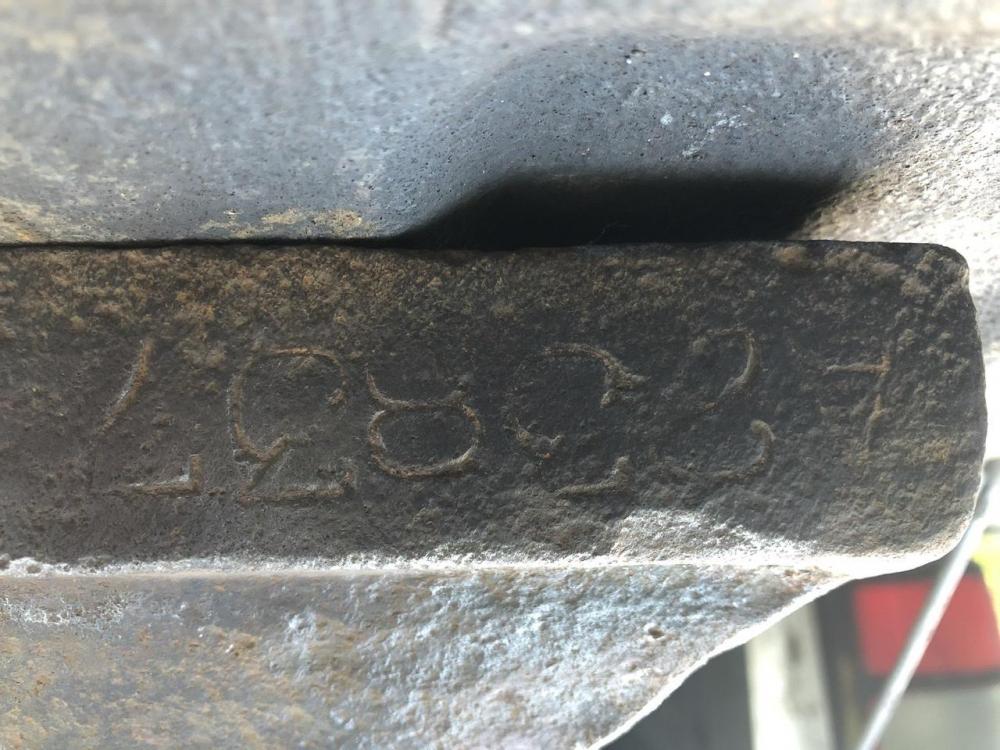

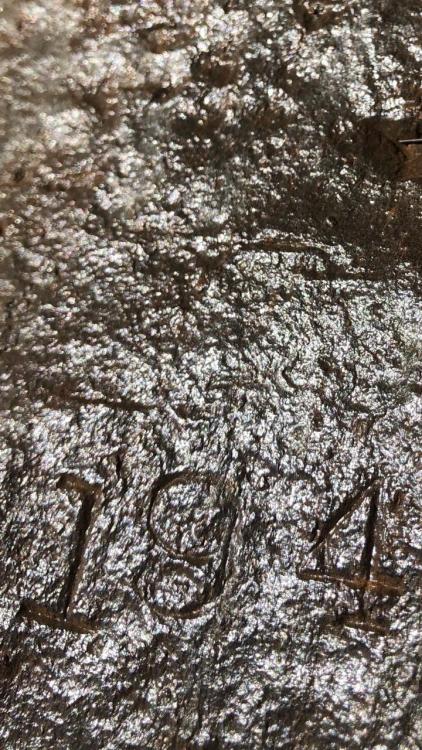

Hauled a tractor for a lady who’s husband recently passed. Noticed the anvil in the weeds. I asked her if she wanted to get rid of it and she said to take it, it’s to heavy for me to move. I gave her 100 bucks anyway and she was thrilled. only found some numbers on it so far, which look like 184. It looks like a PW or maybe a HB but I’m not a anvil expert. Has very good ring and rebound. I thought maybe it just had a hardened steel face welded on but looking closer I’m not so sure. what do you guys think?

-

Yes but I havnt plugged the motor in yet to see if it works. The hand crank seems to move air pretty well though. I think I'll just fab up a damper to restrict some air flow and try it on my forge. Better than a hair dryer I guess

-

Yes the basement of my fire station was a fallout shelter and that's were I got it from.

-

I just snagged this blower that im guessing was used to move contaminated air out of a fallout shelter. Seems like it will move some big air and may be a bit big for my little brake drum coal forge. Was wondering if anyone could provide some info on it.

-

My dad works at the b an o railroad museum and they just pulled this out of storage. At least 500lbs plus the stand. I couldn't find any markings on it but I didn't give it a real close inspection either. It looks to be cast and has a real thick top plate maybe 1 1/2". I didn't get to bang on it but it appeared to be in real good shape. I figured you all would like to see it. I sure enjoyed oogling it.

-

Mastering the reverse blow while shoveling it in has always worked for me. My father was a airport firefighter I have one of those reflective fire suits. They are rated for direct flame impingement

-

Funny you say that. I started wearing a welding glove and now it smells like burnt cow lol

-

Got some great info from so members on here and just want to say thanks again. one question though...... Do most blacksmiths who use gas forges have a mysterious absance of hair on there knuckles and hands? Lol or is it just me?

-

I have a hypertherm 30 and for as small as it is it packs a lot of power. You did real good. My only advise is learn how to use guide bars when cutting something if you want it strait unless you have a real steady hand, which I don't. They make all kinds of guides with rollers and such for cutting different shapes. The ultimate would be a CNc table. I used one at a duct metal shop I worked at and as long as you can use a computer you can cut anything.Thinner material you can run the top right on the metal. Thicket you want to pick it up about a 1/8 the of a inch. I am no means a pro I'm just going with experience with mine.

-

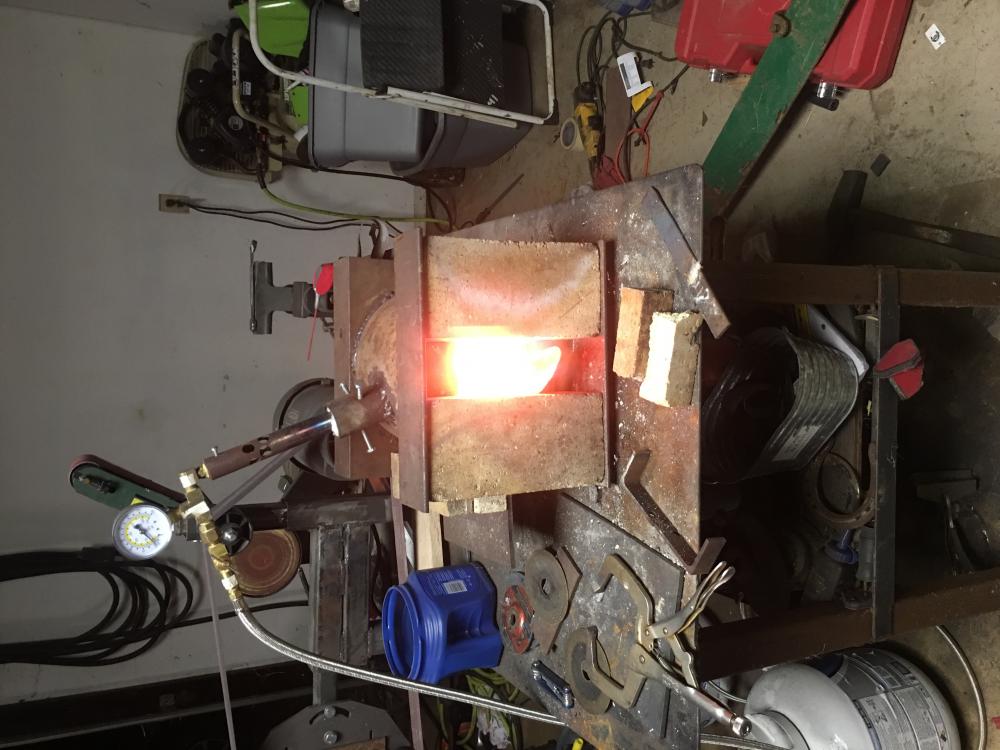

Oh yeah I did. Now I need to find a nice black smithing hammer. My Home Depot sledge just didn't have the nostalgia. Its very nice to use. At 20 psi it didn't take long at all to get up to temp.

-

Many thanks to all the great members of this forum especially frosty who had a answer to all my noob questions. I haven't coated the inside with ict 100 yet but it got up to temp pretty quickly. My build was a oxy cylinder with two layers of 1" koawool sealed with satanite and a castes refactory floor. I'm going to finish it of with a ict 100 coating but I'm happy with it so far.

-

Thank you so much for the help. I really enjoy this forum