Brez

-

Posts

13 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Brez

-

-

Yeah I am waiting on a some castable to come in so I can line the forge with it. It should be here Wednesday and I am planning to pick up some insulating bricks as well at that time for doors. After that I will see how it runs, probably order some metrikote as well after.

-

Well I looked into some basics of burner design (intake opening relative to burner throat, gas orifice position, etc.) and decided I would make some modifications to the burners and see what happened (can always make T-burner if it goes to crap). I made the air intakes bigger, drilled out the old orifice and tapped a TWECO 0.035 tip and positioned it about halfway in the intakes. Definitely made a huge difference in combustion gas flow, noise, and i presume heat output. I am just trying to tune them now. I am temporarily using a loose copper sleeve as a choke. I took some pics of the flame, looks like it is running on the oxidizing side? If all else fails I feel I am learning a lot playing with something that as flaws and figuring out what they are vs. following someone's instructions (the effort of which is still greatly appreciated).

-

16 minutes ago, Mikey98118 said:

I looked at the burners and only find two problems with them: Their designs are poor, and the ycost more than the best commercial burners out there!!! You cold purchase a top of the line Chile Forge burner for two-thirds the price of these JUNK BURNERS. Hybrid burners also cost far less, and come in five different sizes of very hot burners.

That should read "... and they cost..."

Yeah I am not too experienced in this so I thought I would see what the opinions of them were as well. I would also like to point out that the pricing is for a pair of burners so they are $160 each Canadian compared to the $199 US price of a Diablo burner from Chili Forge (roughly $260 + CAN). Thanks for your input though.

-

Hey Guys. The Edmonton Blacksmith Shop is looking at selling their forge burners separately. They have put them up on their website to gauge interest to see if they will choose to make them available for purchase. I bought their forge and though I haven't used it much (and know even less about forging) it seems quite capable.

It would be nice to have a Canadian option for forge burners for those of us north of the border who would like to make their own forge but don't wish to fiddle with burners. I would encourage anyone interested to check them out so they might make them available.

This is not intended as an advertisement and I have no affiliation with this shop. I know I looked a while myself for a burner option in Canada before I just bought my forge.

http://edmontonblacksmithshop.com/blacksmithing-tools-and-equipment

-

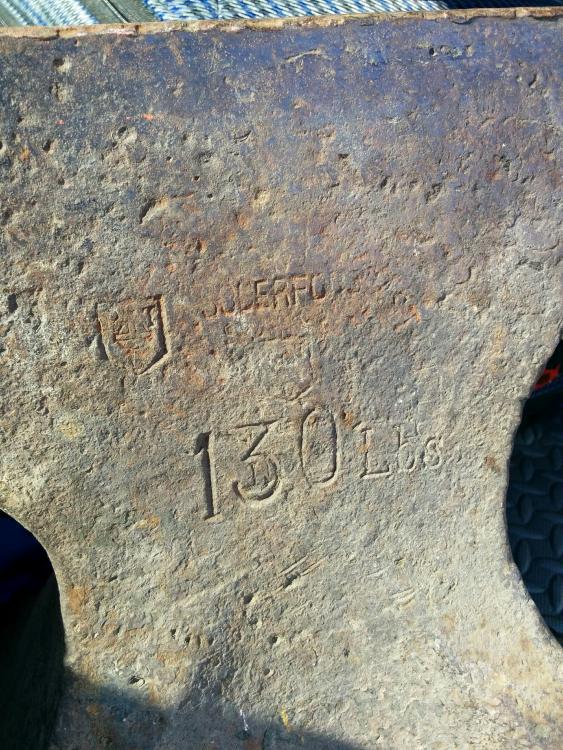

Here pictures of the side with some chipping and the horn which has a few light chisel marks.

-

Cool glad to hear it. Thanks for the information guys. Paid $2.70/lb (canadian) for it and seemed like a good deal. It has a bit of chipping on one side where most of the work seemed to have been done on it but that seems pretty common for these anvils reading about them now that I know what it is.

-

I just bought this anvil I came cross just as I was leaving for vacation off an older farmer type guy. Has good rebound and ring and looks to be in pretty decent shape. The old guy said his dad bought it in the states in the 20s and has been told it is solid steel. Anyone able to provide any more info on what it might be?

-

On 2016-05-22 at 10:52 PM, Charles R. Stevens said:

I would recomend one of two things, either leave it be, mount it with a heathy bead of silicon on a 5" round post and call it a day, 11" face to bash to your hearts desire (tho 3 legs welded on like a joke stool...)

or, if your going to grind and get crazy, cut it down the middle, flip the two simi circles one over the othe and have the "waist" of your anvil fully welded. Now carve a horn, and drill pritchel holes and a hardy (think German double horn).

In truth option one, including fabricating a bick and portible hole is less work and very workable.

Charles, any particular reason for only a 5" round post? I have access to some decent fir tree stumps I was planning on using. As for the rest I am probably going to go the route of simplest is best as you suggested and just use it and make a portable hardy hole tool i can put in a post vice or something. Maybe down the road when I get more experience I can get more elaborate. I did understand what you meant about cutting it in half, though it did take a few reads.

Thanks for all the suggestions.

-

Yeah I had considered that Biggundoctor. Keeping my eye out for a post vice. Just starting out so really all I have right now is the anvil steel and an angle grinder. Have a line on a propane forge but it will be a bit before it can be made and a guy at work is gonna help me with some stuff like making a hammer.

-

Haha I was wondering about that Frosty but you seem to be pretty experienced and I wasn't sure if I was just not comprehending what you were saying.

Thanks for the good ideas everyone I have some thinking to do it seems.

-

Thanks for the advice. I also got a couple blocks of mild steel, maybe I'll put a hardy hole in one of those and mess around with them. Frosty, I am not sure what you mean by existing hardy hole though as this is just a featureless piece of round steel. What I am getting though is it's best to just take the sharpness off the edges and leave it at that.

As for a base my dad has access to fir stumps so he is going to find me a good sized one and I might router out a shallow depression (maybe 1") to sink it in to.

-

I picked up a round piece of unhardened 4340 from a machine shop to use as an anvil and am looking for advice on modifying it. It is 11" across and 5.25" thick, about 140lbs. I was thinking of making 2 flat sections opposite each other maybe 4" long, along one side a rounded edge of gradually increasing radius and the opposite of that an orange wedge shaped piece removed and a pritchel and Hardy hole. I know someone with a heavy drill press for the holes and I have a mini grinder. How feasible is this and what kind of discs would be recommended? New to this so any advice is much appreciated and couldn't find an example of a round anvil like this on this site.

Soon to be anvil https://imgur.com/XJzODyt

Anvil plans https://imgur.com/bD4wf2G

Canadian Source for Propane Forge Burner

in Gas Forges

Posted

I would like to comment that after actually using the forge burners for a while now, I think they worked at least as well before I got my mitts on them. Seems I came down with a case of having to tweak something that wasn't broken.