gofast

-

Posts

6 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by gofast

-

-

14 hours ago, WayneCoeArtistBlacksmith.c said:

For a blown burner I like the Ribbon Burner. Go to www.WayneCoeArtistBlacksmith.com Forge Supplies page. There are two attachments there, one Build a Gas Forge and the other is titled Ribbon Burner.

Let me know if I can help you.

Thanks Wayne the article on the burner is exactly what I need. I might even try making the ribbon burner.

-

On 6/15/2015 at 11:39 AM, Cary Brief said:

how do you flare it the 12 degrees? I have the tubing, wondering what the best way to do it is? thanks

You could use a ball bearing and a press to flare the tube

On 1/16/2016 at 10:45 AM, Mikey98118 said:Maddog states: "These days I make my burner ends out of Mizzou. The 3/4" nipple sits back about 3" from the opening into the forge. I still use SS because I have it but I don't think it matters much."

Now, here's a subject I'd like to hear a lot more on. Could you go into detail a little more?

Me too - how do you cast a nozzle?

-

This is constructed out of propane bottle?

-

1 hour ago, Frosty said:

Welcome aboard John, glad to have you. There isn't a lot of difference in the forge itself between naturally aspirated and gun (blown) burners. The basics of the drawings are fairly good for a forge. There is a LOT of recent discussion here about forge construction and kiln washes.

Probably the most relevant factor to consider is the furnace's volume and shape. A well tuned, 3/4" burner (determined by the nozzle diameter) is generally good to bring 300-350 cu/in to welding temperature, say 2,300f. It doesn't matter if it's a gun or NA what makes heat if putting X amount of burning fuel air in the chamber per second. PERIOD.

Building a gun burner is much easier than a NA it doesn't require the metal shop skills as they're don't require precise work. That just is, no reflection on anybody. I can't tell you what volume or pressure a blower needs to output to work well but more than you need is much better than less. It's easy to gate the blower and reduce it, heck you'll be doing that to keep it tuned in operation anyway.

Frosty The Lucky.

Thanks Frosty! I think I got most of it down and you've confirmed for me the lack of precision needed with a blown SYSTEM which if I'm learning might just be what the Smith ordered.

Seems that you're suggesting the 3/4 will work for the burner nozzle for a blown system? And this would be wide open? not the typical 1/4 npt nipple with mig tip?

If so that's really easy to make!

-

Hi All,

Absolutely new to the forum. I've been fooling with metal for years and have many tools for smithing including two anvils, post vise, swage block, and an assortment of tongs and hammers. I also have a pile of high carbon steel and have booked myself into a few classes. I've taken a few lessons too.

I'm pretty much set on building my own forge and would like to go with a blown burner.

Search hasn't netted me results yet other than this link http://www.iforgeiron.com/topic/19623-forced-air-burner-design/#comment-202388 many other links appear to be broken.

I'm building a Peot style forge http://www.spaco.org/Blacksmithing/PipeForge/PipeForgeAndPropane.htm

Any advise on threads to read or things to avoid would be really welcome. I'm trying to figure out what parts to find for my burner including the parts needed for hook up to a tank.

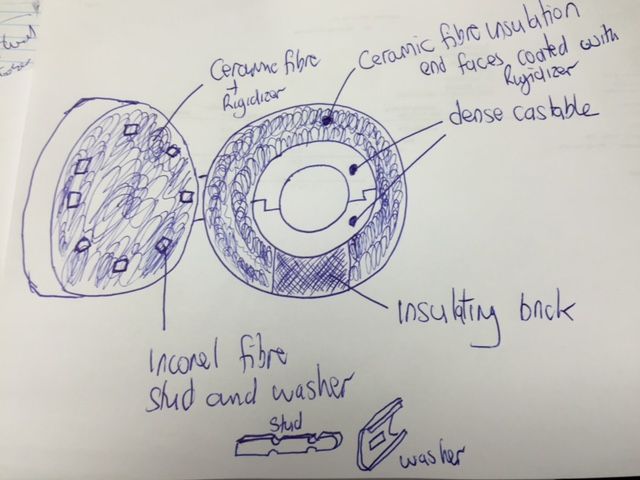

Here's a drawing of the forge design I'm considering:

Thanks,

John

First post and looking for Blown Burner Advice

in Gas Forges

Posted

Hey Mikey,

https://www.abana.org/downloads/pipeforge_plans.pdf

Finally found this after looking for a blower info - shows a simple forge design with plans to build the blower. I'll think I just use firebrick on each end of the forge. When I start learning to heat treat I might buy an oven specific for it.