-

Posts

13 -

Joined

-

Last visited

Profile Information

-

Location

Rhode Island

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Aluminum plate thickness for gate.....

Ashton Flinders replied to Ashton Flinders's topic in Problem Solving

Thanks all for the input! Lots to chew on! -

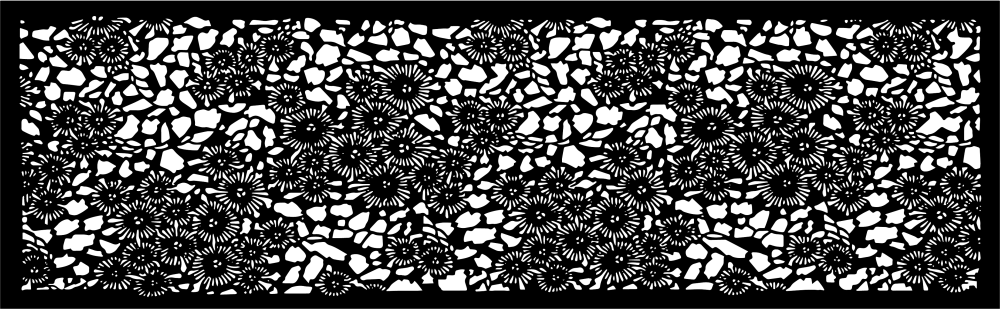

Alohhhhhhhaaaaaa! I am working on a design for a single-swing aluminum gate, approximately 4" high by 13" ft long. The gate would be a plasma-cut sheet/plate of aluminum, framed out in aluminum rectangle tube; either 1.5"x3"x.125" or 2"x3"x.25". For design aesthetics, I want to avoid adding a vertical support tube right in the middle of the gate, and am trying to figure out what thickness I should use for the plasma-cut panel so that it adds structural support. The panel itself has a lot of negative space (white areas in picture) so its not all that heavy (150-250 pounds). The panel includes a sheet/plate border of ~3" inches on all sides, and will have to be done in two sections (no way I can source aluminum plate that big in the middle of nowhere Hawaii...) Any and all thoughts appreciated.

-

So I thought I'd give this a shot. I'm moving to the San Francisco/San Jose area sometime this upcoming summer (June-ish), and am looking for a place to live. I'll be doing a 2 year post-doc at the USGS in Menlo Park (I study volcanoes). Renting is crazy enough already in the area without having to accommodate a 100 lb scooby-doo of a dog, and a backyard forge. If anyone lives in the area (west bay from SF to SJ) and rents out (or would consider renting out) a room/in-law/guesthouse in your dog-friendly, hammer-friendly house, please let me know. Forging is relatively new to me, but I do a lot of other metal work, occasionally throw pots, and used to blow/fuse/slump glass for years. I'm looking for a place were I can keep these hobbies (so room for my welder, a wheel, and maybe space to build a kiln). Let me know! -ashton

-

thanks for the info everyone! -ashton

-

Just curious what you would actually call it..... (fits a 1" hardy hole) Anyone ever use one for edging knifes/chisels/peens?

-

Thanks John!

-

-

I have a fairly typical self-built propane forge with a venturi style burner (actually one of J Prices 1" forge burners). This is not my first forge/foundry build, but for some reason (for a myriad of reasons actually), I decided not to secure the burner the way I usually do (with set screws in a receiving pipe), but opted to invest the burner in the receiving pipe. Yes, this makes the burner position not adjustable (but I'm fine with that, for now). Just curious if anyone else does/has done this, and if you had any issues down the road. I invested it with a watery mix of satanite over the course of several days; this made it well insulated but also pretty easy to chip out if need be. -a

-

(This is a re-post to something I submitted on the ABANA forums a few months ago in their History and Lore section. It's a side project when I get bored...Looking for any and all info. Mods feel free to move this post if there is a more appropriate place for it. Thanks!) I just got my copy of AIA, and in the section on Peter Wright anvils , RP says; "It was reported in Practical Blacksmithing that they made one weighing 960 pounds for the 1876 Centennial in Philadelphia Pennsylvania. I assume it was a Peter Wright because I doubt that Mousehole Forge could make an anvil that large...." However, after some quick google-ing, I found in "Memorial of the International Exhibition: Being a Description Written Up by Buildings" (1877) "BROOKS & COOPER, Sheffield, Eng.-Mousehole Forge. Household anvils, with best double-shear steel gaces. Vises, hammers, masons' and excavators tools. One anvil nearly 1,000 pounds. A fine display, and very article bearing the impress of excellent work and material. PETER WRIGHT & SONS, Dudley Eg.--Same line of work...." (link to google book http://tinyurl.com/q8kwyvb) RP also lists that Mousehole Forge won an award at the exhibition...and another award at the 1880 Melbourne International Exhibition (Australia). This is verified in "Official Record: Containing Introduction, History of Exhibition, Description of Exhibition and Exhibits, Official Awards of Commissioners, and Catalogue of Exhibits" (1882), where it says silver medals were given to the three manufacteres "Brooks and Cooper, Sheffield; Wright, Peter, and Sons, Dudley; Wilikson, J. and Sons, Dudley". (http://tinyurl.com/nhe2ynh) So who's was the 960 pounder, Mousehole or PW's? What happened to it? Did it stay in the U.S.? Did it end up in Australia at another expo? Is it buried in someones backyard in PA waiting to be found? Could it have been shipped to Australia for another exhibition? As an aside, at the Melbourne Centennial, there is an award of merit to "Harper & Sons, Dudley England - Anvils, vyces and tools". I dont find any other reference to "Harper & Sons".... (http://tinyurl.com/qzdjpvt)

-

new anvil suggestions

Ashton Flinders replied to Ashton Flinders's topic in Anvils, Swage Blocks, and Mandrels

Any thoughts on this one; http://www.ebay.com/itm/331599512488?_trksid=p2050601.m570.l4480&_trkparms=gh1g%3DI331599512488.N2.S1.M4642 The serial on the foot is hard to make out, but doesnt that look like a faceplate line on a lot of those photos? -

new anvil suggestions

Ashton Flinders replied to Ashton Flinders's topic in Anvils, Swage Blocks, and Mandrels

Thanks for the advice! I'm in Rhode Island by the way. Out of curiosity, why could grinding/sanding down the face of the Hay Budden damage it? Just from the heat generated? He also has a 160# HB, but for 800 which ain't gonna happen. thanks again! -

I've got two options right now for a new anvil. I'm new to it a bit, been doing metal work for 5/6 years (casting/welding/etc), but just got into forging in the last year. Any advice on the two anvils (A few people have suggested that the PW is the best value between the two, and I could always turn the chipped edge into a nice working radius). Thanks!