-

Posts

39 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by BlackthornForge

-

-

How did you etch the 5160? I'm making some 5160 hunters and I love your patina.

-

Hey, looks good! Did you forge the blade or shape it on a grinder? How did the veggie oil work for you? Did you heat the oil first or quench cold? Obviously you'll want to make sure you're working on sharpening up your grind lines unless you went with a convex grind on purpose (some guys do), but that comes with practice and time.

-

It looks pretty good. I have to ask why did you quench a railroad spike in motor oil? Rail spikes don't have enough carbon to make it worth it unless you mix up some superquench then it might work fine for a while. Motor oil shouldn't be used its nasty stuff, try veggie canola etc oil. It'll be much less bad for your health and it don't smell too bad either.

As terrible as it is, I use used semi truck oil as a quench for RR spikes. I find that the carbon case hardens RR spikes pretty well, and whatever other crap is in the oil smoke feels like a massage for my lungs... I do wear a chemical respirator to keep the gunk out of me, but it's free and like I said, it case-hardens nicely.

-

So planning any others from North America than just folks from the USA? (about to head to work in the United States of Mexico)

Since moving down this away I've been reading up on the spanish explorations and think they would make a great theme for a set of blades and of course the Canadians did a lot of exploring even in what is now the USA---fur trappers and the lost expeditions looking for the NW Passage.

I do hope you do one for a group of american explorers---our Astronauts!

hey, send me a list of ideas and I'll run with it!! I think a Spanish explorer series would be a lot of fun, and an extraterrestrial set gives a lot of imaginative possibilities that could be really cool.

-

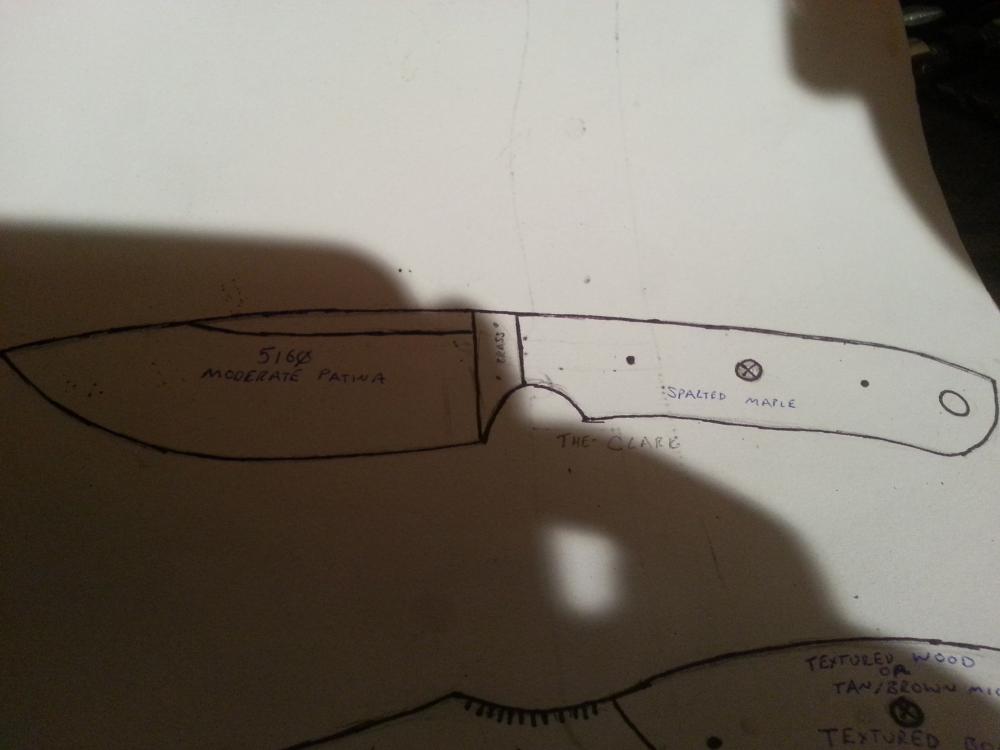

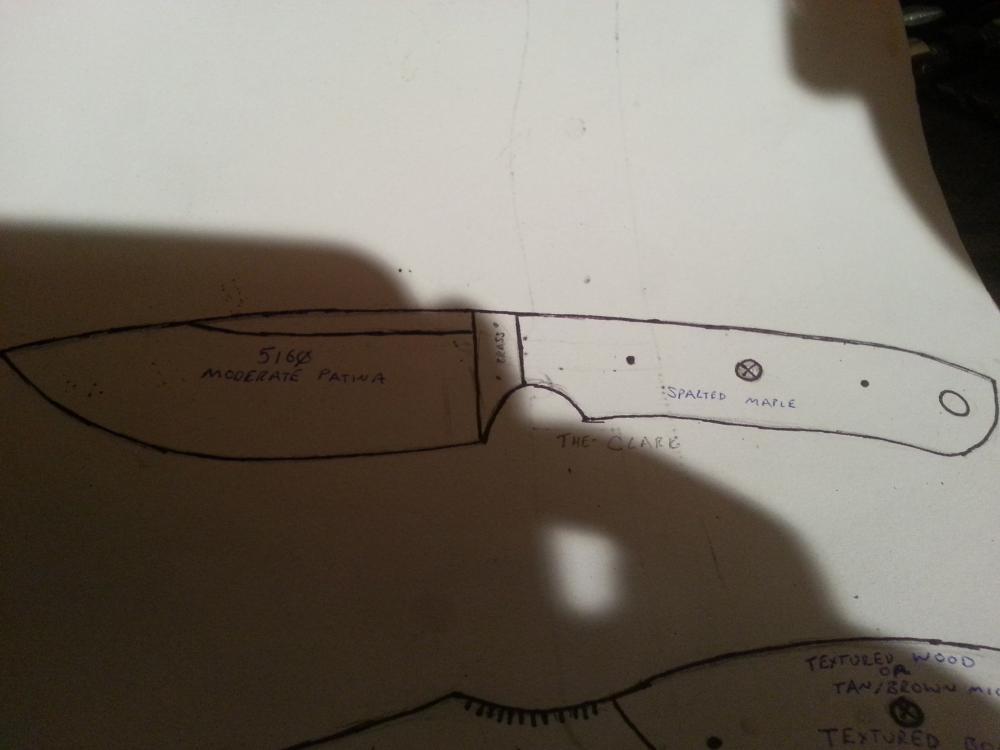

I've been talking to some of you about a skinning knife I'll be making with a checkered handle. It's part of a set themed around some of the great American explorers. The first knife in the set, "The Clark," is a pretty straight forward drop-point hunter. Here's the WIP.

here's the design. Full tang 440c, with a brass guard, pins, and a mosaic center pin, and a lanyard hole.

here's the design. Full tang 440c, with a brass guard, pins, and a mosaic center pin, and a lanyard hole. the beginning grind and rough work

the beginning grind and rough work screwed up my grind line trying to cut corners, so I decided to take the grind clear back to the spine.

screwed up my grind line trying to cut corners, so I decided to take the grind clear back to the spine. and the obligatory injury photo.

and the obligatory injury photo.Working on the polish tonight. More pictures tomorrow. Feedback is welcome!

-

I've been talking to some of you about a skinning knife I'll be making with a checkered handle. It's part of a set themed around some of the great American explorers. The first knife in the set, "The Clark," is a pretty straight forward drop-point hunter. Here's the WIP.... and the obligatory injury photo. More to come tomorrow.

-

would love to se some pics of it when you are done.

I'll definitely be posting something for critique and feedback.

-

I'll keep that in mind and look for a texturing technique that gives decent grip while maintaining the ability to do a quick and easy field cleaning. I generally wipe my knives clean then wash them with soap later, but I like the idea of a quick rub with a Lysol wipe or something.

-

Depends on the definition of "easily cleaned" I suppose... do you prefer a knife that is clean after a quick wipe with a cloth in the field, or are you talking about a soap and water wash without deep scrubbing?

-

Hadn't thought of that. Don't know why. Making it more complicated than necessary I guess. Although, I'd like to use a piece of desert ironwood or line maple and I don't know if I could find that in a pre-made 1911 grip

-

I'll definitely try that. Just a thought: hitting wood with a hammer like that will cause a lot more damage than hitting steel with it. May be best to find a decent framing hammer at a pawn shop and cut the head off to use as a striking surface rather than the striker. That might allow more precision and make the texture more uniform and less apt to strike the same place twice, which would have a meat-tenderizer effect and just tear up the piece.

-

Man, I've been posting a lot for the last couple days. Hope no one's getting sick of me yet!

Anyway, I'm making a little skinner from some 5160 for an American explorer themed set. Because the theme is 19th century (though the knives are of a more modern design), I'd like to use wood for all the handles. Here's the rub: I want the skinner's handle to be very aggressively textured to make it more slip-resistant when you've got your hands deep inside a deer or elk carcass... I'm thinking something along the lines of the popular wood texturing you see on the grip of a 1911--kind of a diamond-y pattern... Any ideas? I was thinking maybe one of those Dremel sandpaper discs without a backing would cut a thin enough line that it would work, but any of the burrs might be too thick. Google hasn't turned up much because most "gun grip texturing" is about how to melt polymer.

-

I've never compared sand paper disks to flap wheels at least not duration ways. The disk will give you much better control of the blade bevel profile. Flap wheels just don't have anything solid behind them, they're more for polishing without altering the surface.

Ian, I am talking about disks on a rubber backing pad. I'm not picturing what you're talking about, can you post a link please? I'm always up for a new tool.

Frosty The Lucky.

Thanks for the tip, I'll give it a try!

-

I think you may have misunderstood Frosty. He was referring to a wheel that has 'slots' in it and it takes a round belt, not a rubber backing pad with a flat disk. As for how sand paper holds out is a science in itself. If an expert in abrasive technology were to give you a quick précis on the matter you would still be listening 2 days later. But for ease of understanding I'll simplify it to four items 1) material to be sanded 2) availability of abrasive 3) cost of abrasive 4) manner of use.

I live half a world away and what I can get and how it's used may be way different from you, so my advice would be to find someone near you that is experienced and proficient and ask if they would let you come and watch? Then once you have a better 'understanding ' of how and what you want to do, start canvassing on where you can get what? To my mind you can get fantastic products from people like Pferd but its far from cheap. Makita make handheld belt sanders that are amazing but far from cheap(I've never even seen one used in the USA) European ,middle and far Eastern shops are awash with them and their deratives . Good luck on your 'adventure'

My grandfather has a handheld Makita. He may have brought it back from overseas though. Great tool!

-

Also what do you guys think of making your own Parkerizing solution? I found this recipe online, but from what I've read about parkerization, it's a pretty toxic and dangerous process. Thoughts?

-

If you want black, "Parkerize" it. Phosphoric acid leaves a nice BLACK phosphoric oxide finish. Follow with oil or wax sealant. I believe you can sand or rub the phosphoric oxide patina down for various degrees between black and steel before sealing.

Frosty The Lucky.

I generally heat my stuff to 250F before I oil it. This may be a dumb question, but will the heat effect a phosphoric patina?

-

how does the sandpaper disc hold up compared to a flap wheel?

-

Yeah. May be better to just use pigmented epoxy rather than trying to use the dust too. Skip a step and all.

-

Lots of info on belt grinder builds on this site and bladeforums. Search for the No-Weld Grinder kit online as well. I've even seen some belt grinder builds with wood frames. If motor on your HF unit is crapping out possibly because it isn't a TEFC motor and is getting loaded up with metal dust you may be able to salvage things like bearings, but those aren't all that expensive. Depending on your scrap pile you may be able to do a build for between $500 and $800 (depending on motor selection, pulley/drive and idler wheel availability, choice of platen type and how well you can scrounge). Typically they cost more, if you use less sweat equity. All depends on what your time is worth. If you are really creative there are alternatives that may be cheaper, but a good, stable, belt grinder is a godsend for making knives.

On the other hand, you can always break the scale off with a 4- 1 1/2" angle grinder with a floppy wheel and draw file...

Is there a way to clean the dust out of the motor? I don't imagine that the motor is actually burning out because I had another Harbor Freight sander that worked fine for years with no issues. I've been using an angle grinder with flop discs to grind blades... not a fun process, but I'm finally getting precise enough that I don't have weeks worth of file work to do.

-

Believe me, I know. I've been using a freakin' angle grinder with a flap disc because my 6X48 harbor freight belt sander is crapping out (surprise surprise)... I'm finally getting the hang of NOT completely boogering up a blade with an angle grinder but it's been a long, rough, and expensive road... If I can make half-decent blades with an angle grinder and a Nicholson file, you can definitely get it down with a 2X42.

-

i read a method where a guy made fine sawdust from the handle material and mixed it in with 2 part epoxy real good and used that to fill the gap, dont remember where i read that tho.

I do that. Works well as long as the material is a fairly solid color. If you're doing a multi-colored material like acrylester or colored wood laminate, the paste usually comes out brown and ugly.

-

I've been reading up on patina for 5160, and I've seen several things suggested. I'm chopping up a partially finished 5160 greatsword to make a few hunting knives. I'm looking for a deep gray, almost black, that will stand up well to use for things like cutting brush, and even light chopping on a HT blade. Most often I've seen vinegar soak, PCB etchant, and gun bluing suggested for dark patinas. I've also found that gun blue won't work on some tougher steels and most stainless. Do you have any experience with a patina on 5160? What is your favorite? Why?

-

I'm thinking about converting my Central Machinery (harbor freight) 6X48 belt sander into a 2X72 grinder. I think the motor is on its last leg because it's bogging down much faster than I remember, and I know there's a lot of work involved, but I don't have much money for the darn thing because I fund my shop through part time shop sales. I don't exactly know where to start on this project, but I figure y'all are the best group of people to ask. Seems like a bunch of you have done home-built 2X72 jobs, and I really think the conversion would increase my productivity and allow me to work to my fullest potential. What are your thoughts? Is this project going to be more expensive than it's worth, considering the crappy quality of Harbor Freight tools? Is there an economical way to do a weld-free build? (I don't have a welder). Any and all advice is welcome.

-

I see what you meant by "sloppy" on my Kris post! Very cool style. My good friend uses 2-man saw blades for his knives and comes up with a very similar "rustic" look.

First (completed) Knife

in Knife Making

Posted

Don't have solid proof for ya, Steve, all I know is that my spikes seem to hold up to a lot more abuse since I started using the oil. Could be something else I'm doing differently I suppose but I don't know what it'd be.