Anthony San Miguel

-

Posts

192 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Anthony San Miguel

-

-

in all honesty, warner brothers did show that one isn't seriously injured if struck by a falling anvil, just shoved into the ground.

Whenever I ask someone if they have an anvil or might know somebody who does, many times they don't know what I'm talking about. I tell them that it's the ACME stamped object that the coyote used to try to drop on the road runner and they ALWAYS know what I'm talking about at that point. lol.

-

An FYI for you or anybody buying their first anvil. I got my first London pattern anvil about 3 months ago and my second around a month and a half later from the same guy.

I used a small ball peen hammer that he had over the entire face of both anvils and got very little rebound. I didn't see any cracks or any welding that might have drawn back the hardness, so I thought they may have been in a fire. But both looked really well taken care and it just didn't make sense to me.

So I went back a week later with my own ball peen and did the hammer test and both had excellent rebound. What happened was that this guy's hammers all had deer antler handles that he had made for them that absorbed most of the energy.

I ended up getting a nice 82lb Hay Budden and a nice 125lb Mousehole forge anvil from him.

My point is, be sure to use a hammer that you trust to give you an accurate judgement of rebound. I almost lost out on two great anvils because of the wrong hammer.

-

I don't know the anvil availability where you're at but around here in central Texas an anvil like that on Craigslist would already be gone. If you think you might want it better grab it before it's gone.

The one for $290, that is.

-

They are bladesmiths. It's a reality type show about forging knives. There are a lot of mixed feelings about it on the knife making forums. A few great makers are competing in it and at least one of the judges is an excellent bladesmith.

I am looking forward to watching it. I think it starts this month.

-

Keep them both. If you get rid of one you will probably wish you hadn't later on, especially if anvils become even harder to find than they already are.

-

WOW! Super cool! Thanks for sharing this. Wish I could see it in person.

-

-

Thank you everybody for the suggestions and words of caution. I'm going to use the treadmill motor to make a 2x72.

I still don't know what to do with the other one. I think the only shop machine that I am especially wary of working with is a buffer. I'm giving serious consideration to taking Mr. Stevens' suggestion.

-

OK perhaps I should have worded it "most knifemakers don't do hamons" unfortunately I hangout with a lot more bladesmiths than stock removal guys (and try to convert the stockremoval guys when I can...). BTW you could just check out Stormcrow's activity on his profile page instead of doing a search.

Was it Stormcrow who made the rail knife? That would be pretty cool because he lives in San Antonio, where I live.

BTW, although I enjoy making a knife by stock removal I enjoy forging one a little more. One day soon I will be good at both.

-

You can get hammon from either forged or stockremoval blades, its a result of the diferential quench using an insulating coating. It has nothing to do with weather the blade was cut out and grount from bar or was forged out as a blank and grount (or filed) as TP points out how sharp the demarcation has a lot to do with steel chemestry and finish.

patern welded (and builits can either be forged or cut to make blankes) is a diferent animal, but again diferent chemistries result in the layers eroding at diferent rates and finishing to diferent apperances.

I understand this. I was responding to Mr Powers' statement that most bladesmiths don't do hamons. I was saying that it may have been stock removal guys that were discussing hamons and eutectoid steel.

-

Well most bladesmiths don't do hamons. Those that do; it's generally other alloying elements that cause problems by slowing down the quench rate needed to form martensite. Plain steels low in manganese work best and often lower than 1084 (1060 for instance)

I must have been confusing them with stock removal guys. Another thing that I remember reading on one of the forums was that a particular maker made a knife out of rr rail and brought it to a show. It was causing some excitement because it had an unusual finish, kind of like a faint Damascus pattern.

-

Well, unfortunately I haven't had a chance to cut off a few more pieces of the rail and experiment a little more. I say unfortunately, but not really because I still got to do a lot of other fun smithing related stuff this weekend.

When I first got the blacksmithing bug a few months ago it started with a desire to learn to make knives. From what I've gathered, bladesmiths like steels that are close to the eutectoid (around 1075-1084) because they can usually get a good hamon from them. A hyper eutectoid steel to a bladesmith is primarily exciting because of the higher carbon content but they don't usually produce a good hamon for various reasons, one being that some are too shallow hardening.

Mr Sells, I know that you are a bladesmith and I'm glad that you jumped in here. I plan on buying your book within the next week. Are my statements in the last paragraph correct?

-

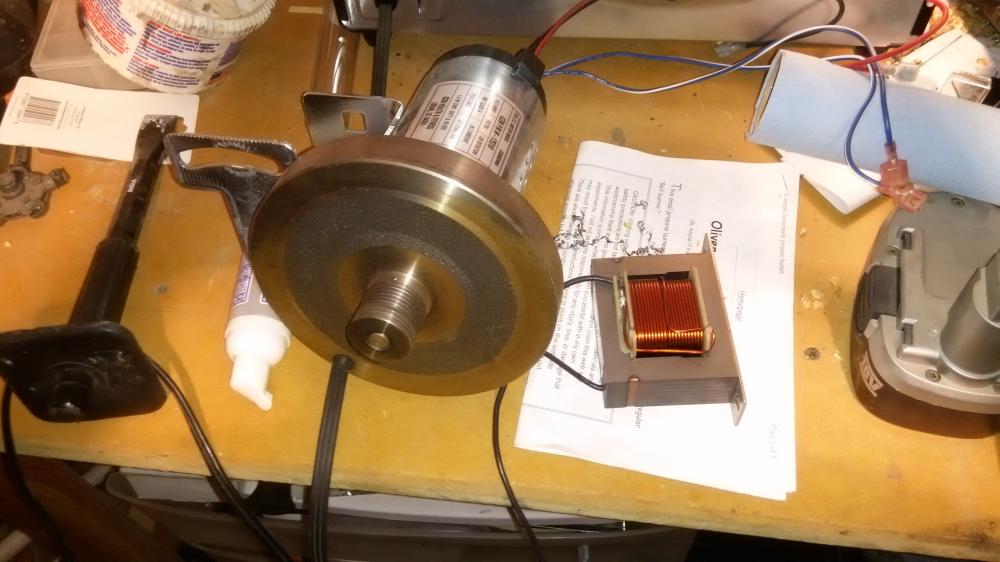

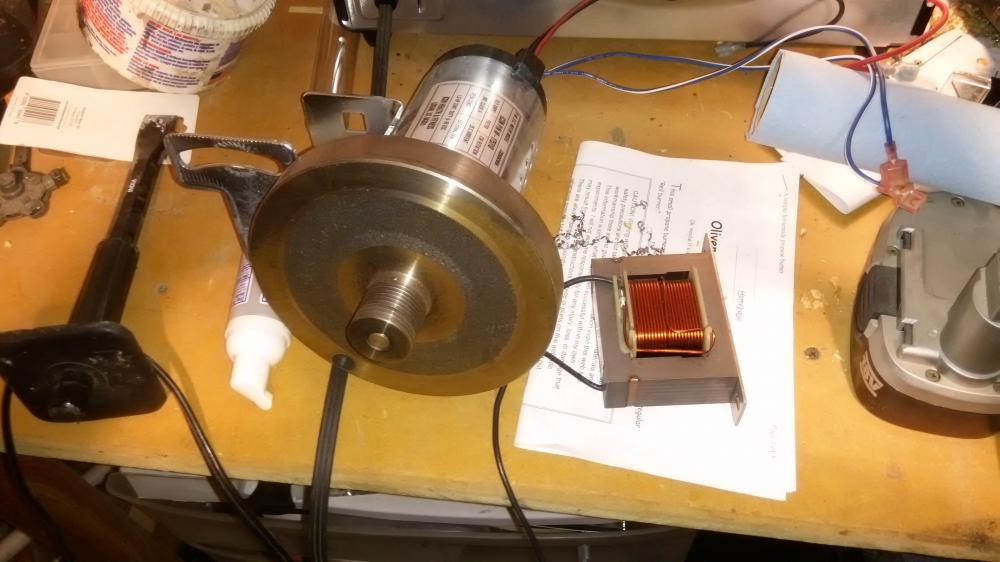

On the top motor I would be hesitant using it as is. That is a lot of overhang for that small shaft. I had a 5/8" bar sticking 18" or so out the back of the lathe at work that bent from centrifugal force when I sped the lathe up. I was new on that lathe, and it is very quiet , even at 4,200 rpm. I was doing an operation on the end by the collet, and just eased the speed control up a bit. The next thing I know the lathe is hopping, and making a racket. The bar had bent into a 45° or so angle, and had whacked the electrical cabinet before I got it shut off. That happened at somewhere around 2,000- 2,500 rpm from my best guess.

Thanks for your reply and your words of caution. I don't take things like that lightly. I just wonder if maybe the pics were a bit deceiving. I don't think its as long as it

looks overall. Tell me if you feel the same way after these pics... I don't see a name on the drill chuck.

looks overall. Tell me if you feel the same way after these pics... I don't see a name on the drill chuck.As far as the treadmill motor goes, I was leaning heavily toward making a 2 x 72 but all the ones that I've seen or heard about used a motor with less than 2 1/4 HP. Is there any good reason not to use it for a belt grinder, other than having to make a filter to shield it from metal dust?

-

I got this at the flea market for ten bucks after a 30 min conversation with the seller. Assuming that it works (guy promised it did), what should I do with it? It already has the chuck on one side so I don't know what to do with the side with the pulley. What would you

do with it? The motor is an old 1 1/2 HP GE. I also already had this 2 1/4 HP treadmill motor that I know works. So what would you do/make?

do with it? The motor is an old 1 1/2 HP GE. I also already had this 2 1/4 HP treadmill motor that I know works. So what would you do/make? -

Good morning everybody. After reading Patrick's post (thanks for posting, by the way) my curiosity was further peaked so I had to find out what would happen to my "HE" rail if I tried to harden a piece. Well I cut off a small sliver with a hacksaw because my friend has my bandsaw right now and curiousity didn't allow me to wait for it.

I can tell you that it hardened just fine. This was with a crude hardening process for any hyper eutectoid steel. I don't know if my piece of rail was ever under stress from having a train run over it or if the manufacturing process stresses it, but I didn't even normalize it. Just cut a sliver, let soak above non magnetic for about 5 minutes in my brick forge and straight into a large jar of canola oil. The grain is pretty fine. Not as velvety as a good file gets, but still pretty fine, without normalization.

In the pictures you can see where I filed it before hardening and it filed surprisingly easy. After hardening and removing the scale a good NOS Simonds file would skate off. Also, there was no flex at all after hardening. Just broke like glass.

Here are some pics. It will probably be hard to see the grain structure in these pics, but they were taken with a cell phone and it's the best I could get. When I get my bandsaw back I will cut and experiment a little more.

-

Okay, email sent. If it still isn't clear enough I can fax the actually copy but it's at home so I wouldn't be able to fax it until tomorrow.

-

hmm there is an Arcelor Mittal foundy right outside El Paso off of I10; I have a student who just switched their major to metallurgy from philosophy that I have encouraged to see if he could intern with them...

IIRC NCO swords were forged from Manchurian RRR by the Japanese in WWII.

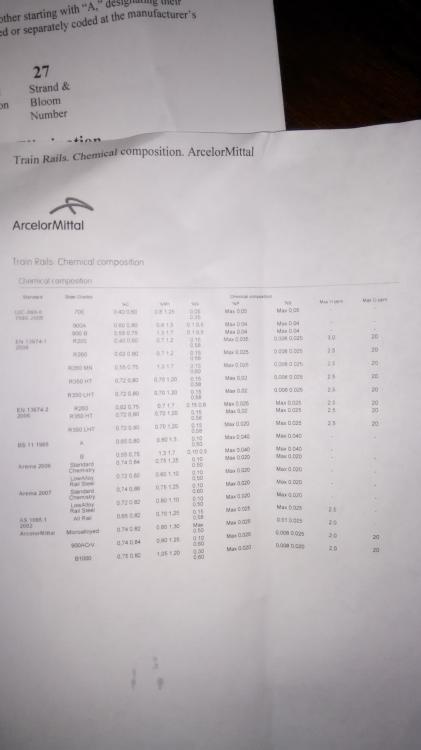

would it be possible to get a clearer read out on the data? I would like to add it to my RR Steel file as another datapoint.

If you send me your email address I can email a better copy. Other than that, I was unable to link from the site to this post. Don't know why. I wish it had come out clearer. It's clearer on my computer.

-

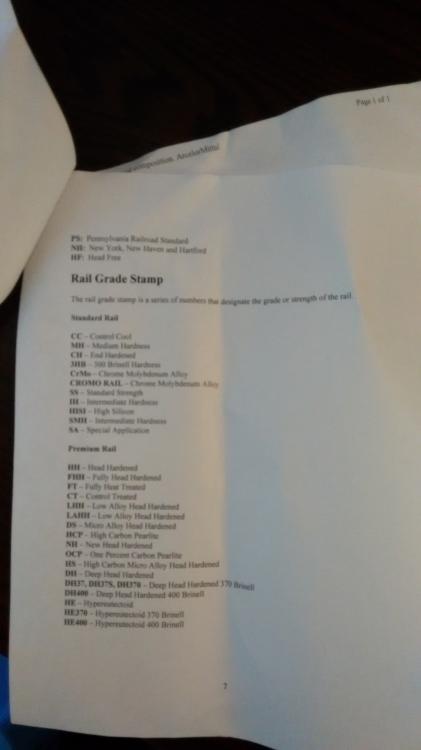

Hello everybody. I know just enough to know that I have a lot more to learn, but as this site has contributed a lot to my short smithing journey I would like to contribute a little something I found interesting while I was in search of something to use as an anvil. I believe others here will also find this interesting.

Like most beginning smiths I was in search of a good piece of rail to pound steel on but I happened to get my hands on a whole bunch of it. All different lengths and sizes with various markings, but most was heavy main line rail. I made a few horizontal and a few upright anvils and ground the webbing on some into bottom fullers and shaped the flanges of some into hot cuts. I then began grinding different shapes into the heads of some to use as swages.

But I had way more then I needed so while trying to decide what to do with the rest I started researching rr steel composition. I went to different manufacturers websites and called a few manufacturers and found that the general consensus of this website that rr rail is about a 1080 is correct. One rep even read to me the specs of the last shipment of rail that went out and I don't remember the manganese content other than it was high, but I do remember the carbon content was 0.77.

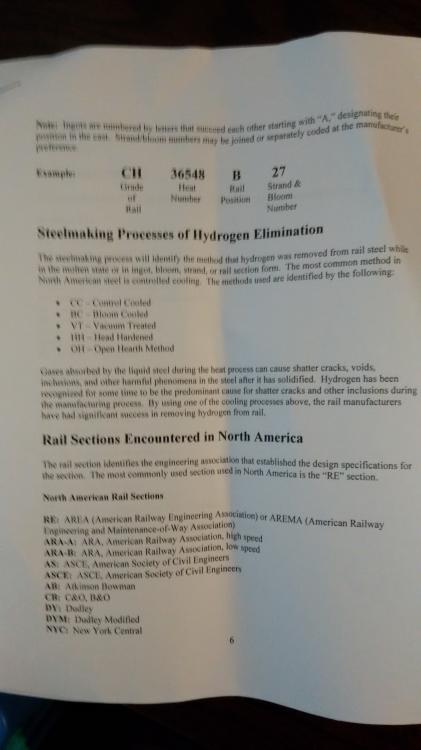

Well, here is what I found the most interesting. I found an AREMA (American Railway Engineering and Maintenance-of Way Association) guide for identifying rail defects that lists some of the abbreviations that are stamped into the sides of rail and the HE abbreviation stands for Hyper Eutectoid. Well I have a piece with this stamp in it and I'm using it as a vertical anvil for forging knives primarily. It does a great job as an anvil, but I'm thinking that that piece alone is about 90lbs of great knife steel! I know that I don't know which hyper eutectoid steel it is, but based on its intended use you can probably make a good guess about which ones it isn't. It's constantly stressed and has to be springy and have some flex to not break under load. Maybe 1095? I know there would be a wow factor with some people knowing that they just got a knife that is made from rr track. I know I think it's cool.

Anyways, for what it's worth, here are pics of some docs I got some of my info from including the composition guidelines for Mittal, a major manufacturer of rail (the rr rail says AREMA in front of it), and my HE rail anvil.

-

Here's a new addition to my shop. A 170 pound "no name" hornless anvil I had recently brought in from Europe. I had just finished the stand and took her for a test drive today to find its personality. Got some nice curves and has decent rebound considering it was from prior 1850. Fairly quite compared to the two S&H's in the picture. I will be using this anvil doing demos at Renaissance and Pirate Fairs in my local area.

Wow! I love it! Looks Austrian.

-

If you look up the video I did on cable damascus you can see my use of a similar hammer. Search the forums here or just google 'jwsblades', I've got a small video page on my website - just because its an auto body hammer doesnt mean theres no use for it in the forge and out of the box uses seem to present themselves once you have it, heck, I've forged entire bladed with mine!

Happy swinging!

Happy swinging!J

I just watched your video and saw the hammer that looks like mine. Pretty cool! When I bought these hammers I knew they might not have been made specifically for smithing but that doesn't discourage me from using them that way, if they'll work. Looks like you made yours work just fine.

Turns out the one I thought was some sort of flatter isn't even a metal working hammer at all. I'm still going to try and see how it does. I won't even have to switch to my brass hammer because the struck end is hard rubber.

Thanks for posting!

-

Lol. Good to know. Thanks for the reply. Since I don't do any wood flooring and the hammer was cheap I may try it on some hot steel anyway.

-

Thanks for the reply, Gergely. I think you're right about it being a flatter, but not for blacksmithing. The struck end is made of a dense, hard rubber. I'm going to try it on hot steel anyway and see how it does. If for whatever reason it doesn't work well I found a large rr bolt with a square head that I plan to make into a flatter.

-

Please don't take a grinder to it. I doubt it's a cast aso. Those handling holes aren't there for decoration. Way better to take a ball bearing or small ball peen hammer and check for rebound. If the anvil is dead, you don't want it. Even if it sparks well it could still have a delamination problem you wouldn't know about without doing a rebound test.

-

Very interesting. Thank you Mr Powers. I'm having ALMOST as much fun collecting and learning about the various tools and their uses as I am actually hitting hot steel. ALMOST.

Help Identifying This Anvil

in Anvils, Swage Blocks, and Mandrels

Posted

The horn doesn't look like a Vulcan's horn. The picture you posted won't enlarge. Does it have handling holes? More and bigger pictures would help identifying it.