matei campan

-

Posts

405 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by matei campan

-

-

I checked that on anvilfire and it seems it's not bad at all. today I checked the rebound again with the help of a ruler and I got the confirmation of what I estimated by eye - 80% and just slightly over at the best rebounds. the surface is not perfect and clean, so not all are as good.

there are a lot of no name anvil copies made during the communist era around here, as cast steel was cheaper than a new commercial anvil, which I think it wasn't available on the market (communist economy). some time ago when I was looking for an anvil I was offered to cast one for me for a ridiculous sum of money, but I got a fixation for a "real" anvil and didn't get it... and now the opportunity is long gone. If I would have had my mind of today I would have been making an anvil model of mine to be cast. -

hy guys

today I received an anvil I was expecting for almost two years - transportation problem, it was in the other end of the country...

it's a no name copy of the southern german pattern (like this http://www.anvilfire.com/anvils/greenwood_anvils_011.php), but not as beautiful, especially the conical horn which isn not quiet conical, but rather a rounded pyramid, and also has a casting flaw, something like a miss alignment of the two halves. but's not a problem, I have other anvils which have nice horns.

anyway, it has something around 160kg and has a flat face, in good condition.

it seems to me that it's a cast steel anvil, it rings nice and has a rebound that I estimate ~80%. also the file seems to skate across the face and the 2.5mm ball bearing used to test the rebound doesn't mark the face.

so, how "good" is that rebound, is that a sign that's a good steel? -

thanks you for the appreciations, that gives me the courage to share more pictures in the future :)

-

hello!

even that I'm visiting your forum from a while, I haven't yet posted anything made by myself.

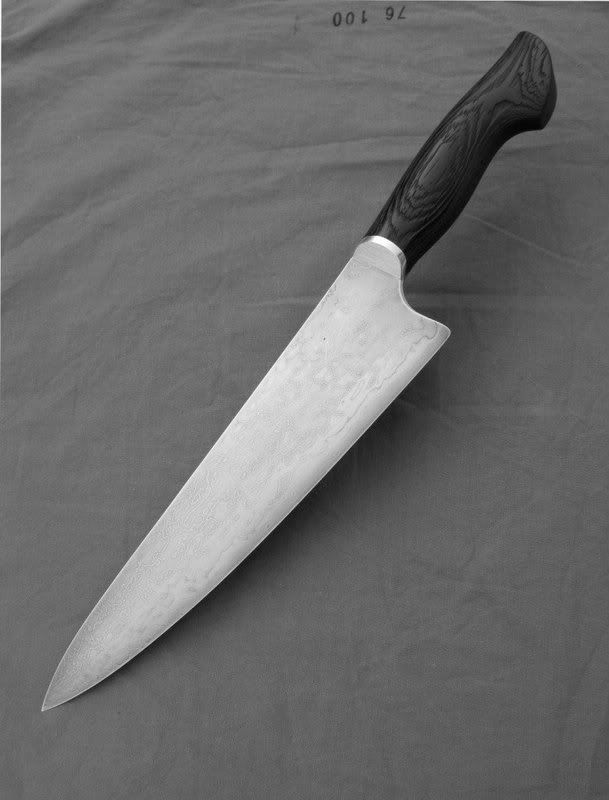

so I'm starting with a "chef" that I just completed.

the blade is forged from the 22+1layers Takefu Suminagashi steel, not very spectacular as look for a damascus, rather "subtle", but good steel, very easy to get an extraordinary edge from it.

the handle is wire brushed wenge wood, the bolster is made from 3mm brass sheet, bent at 90 degrees, to allow a better grip on the blade, pinched with the thumb and the index, as is used for the chef knives.

if the pictures appear cut on your computer, you can see the album here:

http://s908.photobuc...-campan/RRchef/

-

anyway, the "X" is in fact a "N", with a strange design which makes it be confused with the "X". you can see that the the "X's" lines doesn't just simply cross each other in the middle. it's an example of poor graphic design - wanting to be too cool, leads sometimes to confusions.

nice anvil! -

bolting down the anvil on the stump like the one of Macbruce's picture in this thread: will kill sound at least as effectively as the solution above, instead is easier. I done it on all my anvils and the difference is big. and the trick with the tar paper may help also.

it kills all the "bell ring" of the anvil. -

nice!

and as I already said, that clutch needs a wider belt to work properly, as in the photos in your link, not as "my" hammer has now. originally the belt was similar - wider leather one, now it has a canvas/rubber or some resin, composite, the type used for other machinery, not too appropriate. -

yes, it has a lot of "whip" and it hits very hard at full power, in the video the hammer runs at slow speed.

I think the "lot of whip" is due to the large bow spring (~ 60cm large, almost 2feet), which allows extra travel for the ram without being too "lax".

for the same amount of money the widow asks for the hammer, I could buy a self contained. in fact I already bought a perfect running one for 330$ at that time, a 100kg ram weight one, unfortunately there was a sad history after I bought it, too long to tell, so I don't have it anymore. anyway I didn't have a place to properly install it. so a tire hammer would be the solution now, just to have some time to make it. -

a machete is good for it's purpose because it's light and thin. I have 4 machetes, but i use mostly a bolo type one - it's light and, because the "bulbous" tip, has the weight more forward than an equivalent "latin" shape one. that's what I have: http://www.machetespecialists.com/tr14bomawiha.html

the machete works by speed (due to its lightness)and penetration power (due to its thinness). apart of hammering, where the hatchet could be used, I can cut wood/branches as well as with a twice as heavy hatchet, and it's even better for thin, flexible unsupported branches, where a hatchet just recoils by lack of speed.

another thing - the swept forward shape of the blade is quiet unstable and much less versatile than a straight or a slightly up-swept one.

is that a bottle opener there on the back? -

yes, that's it, it's quiet fast to remove the dies.

-

thanks for your video!... I'm not able to say more than the other guys have already said...

and what I liked also is that all seemed so familiar to me, so "central European" (even that you're mostly "northern" than "central"), in contrast to what I'm used to see around here, so "American". -

I"m glad you guys like it. unfortunately, the shop and the hammer are just rented to my friend. the workshop and the house along are for sale, so he don't know how long will stay. also the hammer I think is for sale, but i think my teacher's widow asks too much (you know, for sentimental reasons). so my friend it's not very keen to rebuild and improve the hammer. It's a pity, because the hammer is very well build and, with proper maintenance should last several life spans. I'd change the clutch system by a simpler one, maybe a tire sistem or I'll improve the actual one. also I'd change the toggles by adjustable ones, even that the originals non adjustable were working very good. you can see them staying almost horizontally.

but I'm not buying it, unless the woman will sell for a really reasonable price. I'm in train to build one for myself, I have most of the parts, i just need some pillow blocks and some shafts to be machined. It will be a tire hammer.

I also saw that clutch system in old "industrial" photos, with machines driven by belts from main shafts. -

recently I visited a friend of mine who actually works in the shop of a passed away teacher of mine (RIP!). I brought also the camera to take pictures of his power hammer. I can't remember the history of the hammer, but for sure is a "fabricated" hammer, not a factory build, even that's not a "JYH", there's nothing "scrappy" about it. I suppose it was built for him sometimes at the end of the 70's when he was working as public furniture designer for the municipality of our town, so he had access to many local factories and workshops.

this hammer was the first power hammer I saw in action, some 20 years ago.

unfortunately, after the death of my teacher, a little more than 10 years ago, the workshop was rented to different people who didn't really care about it and the tools in it, so it's not was it used to be anymore.

I don't know the exact ram and anvil weight, maybe the ram is something around 30kgs, but the hammer could hit very hard.

even that the hammer is not really bolted down, it doesn't move or "dance", it's a quiet massive build.

here are some pictures of the hammer, hope you enjoy:

the toggle old and used original toggle arms were replaced by my friend by ones forged form rebar :) not a technical genius the guy, fortunately he made them the same lenght, as they were not adjustable

above you can see some of the dies, which my teacher said that there were the most expensive parts, made out of special heat rezistant steel. even today after a lot of abuse and lately the misuse of different persons, the dies are in very good condition (apart of some rust, because of the rain infiltrations)

below is the clutch system which consist of a drive belt which is moved from an "idle pulley" to the "working pulley" by a "fork"

in his good old days, the drive belt was larger, allowing for better control of the hammer.

the "lever system" which transmits the movement from the foot-rest to the "fork"

the flywheel doesn't have a counterweight, but instead has weight removed form it

here it is a short video, I hope it works. I asked my brother which has never used a PH to "move" it a bit

-

hello, and "bine ai venit!", I'm from Transylvania, too, from Cluj, but now living in "exile", in Sibiu...

that anvil pattern is the most common around here, maybe in the whole central Europe, from Austria to Romania. it exists as original and as local copy. I have two of them, a 32kg original one, JEB is marked on it, and a ~70's local copy of +100kg.

the shop is very typical village's shop around here. very nice that you posted it. thank you! -

How can he tell it's 400 years old? The shape looks like a relatively modern European anvil and it's got a hardy hole.

I don't know if it's true... doesn't matter for me. I just like the pic of that bunch of anvils.

and don't take seriously what I said about your anvils. I'm just salivating in front of your anvil pics, too. that kind of anvils which are popular in the States, you can't find too much around here, where the austrian pattern is the most popular.

apart of the 2 austrian pattern anvils, I'm a proud owner of a french forged (I suppose)one. I hope to post some pictures as soon as I can -

guys, I'm sorry to say that most of your anvils are boring:) they all look the same...

until i'll post pictures of my anvils (not very soon, but I promise I'll do it), just check this guy's anvils:

from time to time I visit his page and open that photo (and those with axe heads) and I'm salivating in front of it...

am I sick? -

thank you Madmike, i was just curious hou much could be such a tool.

and "bonne anniversaire!" -

yes i know them from the net and i saw one in reality when i was in France, but not during working. is a new Tyro more expensive than Anyang?

-

in fact i'm reading things about Anyang on the net from some time, but i've heard contradictory opinions. am i right that the quality what you get depends greatly on the dealer's amount and quality of involvement? i feel that the US and UK dealers are really committed to their mission. our dealer, 2-3 years ago, told me that that's me who has to go at the customs in the port where the ship arrives ad do the import formalities. so, i don't know which is his mission if i have to do the job? it's true that not having the money to buy, i didn't talk to him in detail about the business.

Madmike, being "francais", have you heard about that TYRO french mechanical hammer ? -

helo

here are some others:

as i said i want to build myself a mechanical one, but i'm still in doubt: would it be a "rusty" or a tirehammer? i've got the most important parts (anvil, base plate, springs, motor...)

but when i'll have some money i would like to add a self contained hammer. here i could buy an old localy produced one, minimum ram wheight 63kg.

an other option is Anyang, as there is a dealer here. i don't know how serious he is, yet.

in case i decide to buy one, what do i have to look for, what could it go wrong ( dealer, mechanics, parts supply, service, etc.)?

or does it worth to spend more and buy Sahinler as there is a dealer, too?

thanks -

thanks for apreciation, it's alwys good for the soul.

i mentioned that the italian link works on internet explorer, if on mozilla it requiers plug in.

i posted the italian hammer link because it intrigues me also. i found it by cance on the net. i don't know the prices.

i'm not from italy, but from romania (other "latin" country)

have a good day friends -

hello friends

i'm visiting your forum from time to time and i'm enjoying it. i hope to build a mechanical power hammer one day...

here is an interesting mechanical produced in italy, just for the pleasure of your eyes:

i think it works just on internet explorer

matei campan

knives2use -

hello,

it happens that i have a ~100 years old french 101kg anvil which it seems to be a forged one. it also seems that is made out of stacked pieces of steel. if you're looking at the surface you can see the welding lines and it looks like been made out of bricks, similar as in cable damascus, but much, much larger and rectangular. i also saw a video on youtube about manufacturing a huge forge-welded anchor some 100 years ago. they also build up material by forge-welding. another story i heard from one of my teachers about a gipsy blacksmith (a rural smith) who forged him an axe head out of a kilogram of nails, back in the seventies. he surery didn't ever hear about Mr. Moran.

these guys just didn't know they're making 'damascus'.

just imagine the several tons damascus anchor

matei

knives2use.blogspot.com

anvil rebound?

in Anvils, Swage Blocks, and Mandrels

Posted

the hammer runs nice on that anvil, too