-

Posts

39 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by neilyeag

-

-

-

I did exactly the same thing when I started out. Just used a sledge head, mounted in a holder similar to yours. Take your time and it will work just fine. I also made several greenwood bowl turning tools.

-

Not at all, if I was in my shop, would have gladly checked it out for you.

Neil

-

Lou my forge is up country about 300 kilometers away from Bangkok where I work, so wont be back for a couple of weeks. Easy way is just to shoot Glen an email, he will give you all of the details.

Neil

-

Lou, I have a complete set of his handled top tools and am really happy with them. They work flawlessly and as you said I think are really well priced.

-

Yes it is really nice. Check out Glen at GS Tongs dot com. He make a lot of really nice tools.

-

Gergely - Beautifully done!

-

lyuv - I had mine made by GS tongs, very reasonable and really a nice punch.

-

Yes, from Glen, GS Tongs. Nicely made and very functional.

-

On 1/7/2018 at 2:36 AM, BIGGUNDOCTOR said:

neilyeag, that wood in the base looks beautiful, what kind is it?

It is a local wood called Mae Daeng. Very heavy and dense. It is tough to even drill a pilot hole for a screw! So perfect for this application.

-

58 minutes ago, BIGGUNDOCTOR said:

Why stainless? Mild steel is fine and a LOT less expensive.. This block was burned out of 2" thick scrap plate and is around 18" or so square. The smaller round holes(not done yet) were to be drilled instead of burned out on the CNC oxy acet torch. With a clean tip the right size the plugs just drop out and there is little to no dross to deal with. Plus the remnants can be used as tools too. Want a 4" thick one? Burn two and either weld or bolt together.

Thanks for the feedback. The weird part is in terms of steel cost. Here for this small size, I can buy SS for about the same price as S50C. Machining becomes the cost factor. Your block looks very versatile BTW.

-

Yep Glen does a good job reasonable prices and great quality.

53 minutes ago, genesaika said:It looks fantastic! Two things though, where's the pics of it burning and can I get a better pic of the rack on the right? Please and thank you !

Old pic of fired up:I spent all last week getting stuff moved around and set up and did not even get around to light it up.

The other pic is a holder for the top tools:

-

Yep, I kind of thought about this after it was all done. The top two layers of the stand are oriented at 90 degrees, but should have made them grain up. But this is removable so I could change it. The rest of the stand is kind of like a box. It is filled with gravel and sand. So it is pretty darn solid.

See the other reply on the anvil.

11 hours ago, JHCC said:Have you done a ball bearing test?

Not yet, will check that out in a couple of weeks when I am back up country.

-

5 hours ago, ThomasPowers said:

Nice set up. But way too clean!

Only for this shot. I just moved everything all around so I cleaned up and moved all of the other stuff behind the camera!

4 hours ago, Marc1 said:Your hammers are on fire! he he, the first thing I thought when I saw your photo.

You have a bunch of those offset tongs ... I like them too. Are they locally made, made by you or ... the usual made in Pakistan?

Yes from GS Tongs. I really like them, very versatile and really gives you a solid grip.

-

Actually I did not think about that. The only issue would be that I am using the mill to cut them, so the curf would be quite wide and I would not end up with perfect half circles. Not that it makes any difference!

-

It is solid solid man!! Part of the reason is it is basically a solid steel box, so you have a huge amount of mass throughout the entire anvil. The anvil is all done on CNC, I only made the horn flat on the prototype because I was not sure exactly how I wanted to shape it. I will likely ease the top edges slightly and then the bottom edge stronger, coming to basically an oval shape at the end. (using my BAAG big xxx angle grinder!) Once I decide on the final form I will make another prototype. I hope to market these if I can get the shipping logistics figured out. Because they are CNC, I can offer some customizing features for the user/buyer.

-

My Thai neighbors think I am out of my mind. Out there banging on hot metal when it is 40c+. But this time of year it is nice. I the morning maybe in the 20c range. I fabricated the anvil myself. 90 kilo- S50C steel.

-

Thanks, I will. What do you think of 304 for these? Should be OK, but I have not banged on them yet. I want to have at least 4- 5 designs finished and then I will offer them up. I think with this weight sending via Thai Post- then through Royal Mail will work OK. Now how to send my 90 Kilo anvils is another story!!!

Neil

-

Nice Looking machine!

-

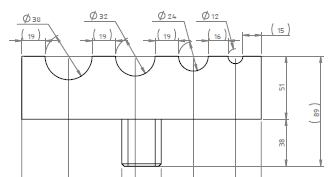

You know I finished these up just before the Christmas break and then grabbed everything and went to my upcountry house where my forge is and I did not even check the weight. They are machined from 304 stainless (no heat treat). Started with 89mm wide x 194mm long and 38mm thick piece. The hardy pin is for my 1 1/4" (32mm) hardy hole. (51mm is above the anvil and 38mm hardy pin length) So this is one solid piece no welding whatsoever. I think they have to weigh around 2 1/2 kilo finished. Took me over 3 hours, but I don't have all of the right tools and my mill is all manual. Plus I am not that proficient! I will likely do some other prototypes and other configurations I have in mind and then perhaps offer them for sale.

-

Bottom Blast. The title should be Charcoal Forge. I have never seen coal here in Thailand. Maybe it is available. The charcoal is locally made and works quite effectively and is very cheap so cant complain.

I fabricated the anvil myself. I have some other pics under show me your anvil section.

-

Yes this is solid, Kind of put together like a big steel sandwich. 1 1/2" steel plate.

-

Really excellent design and execution!

-

.thumb.jpg.05028db0e13fe1cb0ffc148a17257ad8.jpg)

Forge-finished finery, bush swords, etc.

in Knife Making

Posted

I really like the wrapped handles. I tried a couple of times. Watched the videos on how to do it, got started and then the brain went spazo! I could not get it right for nothing. Yours are all well done.