Blackcatbones

Members-

Posts

20 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Blackcatbones

-

That is true. Looking at it today im thinking it should be just fine the way it is. Im finding this is a steep learning curve but I have a little feel for it. In high school metalshop class a large part of the curriculum was blacksmithing. I was right at home there but the equipment was also new so I look at the equipment I have available now and in my mind I keep comparing it to that class setup lol.

-

Perfect that all makes sense to me, ill leave it alone. My concern with the face is im often told for forging blades you want a pristine surface or the marks will transfere. Im not overly worried about some marks but I want to avoid huge amounts of grinding (defeats the purpose of getting away from stock removal) ill give it a try as is. Sounds like it will be ok. Thanks!

-

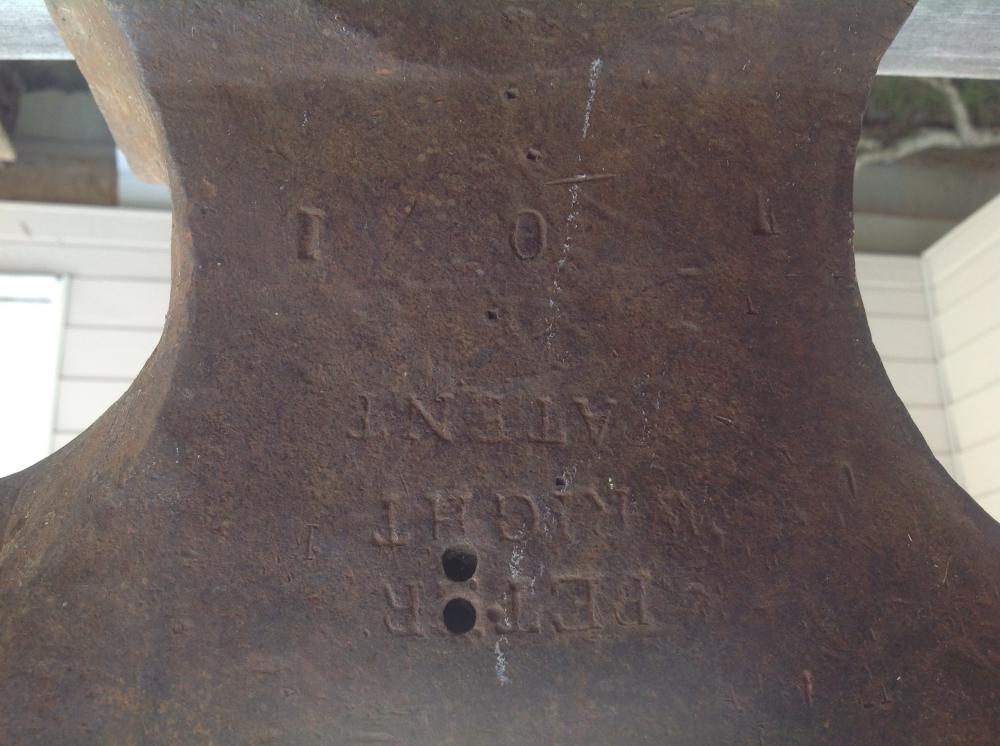

I want to move my knifemaking from stock removal to forging. I have an old Peter Wright I picked up a few years ago. So far its just been sitting around gathering dust while I try to come up with a game plan. Now I want to get this whole thing going. I once had some info on this anvil but have not been able to track it down. Near as I can tell its around 100 pounds. Ive included images of the factory marks as well as the various damaged parts. Sorry I dont know of the images are upside down or not. I post from my ipad so they tend to post upside down... No idea why. Gravity perhaps ? First issue I want to deal with is the face. I want to resurface the face to make it suitable for forging blades. For this im thinking of using a grinder and going slow as to not heat it up a whole lot (possibly in an ice bath to keep the temp low as possible) then moving to a flap sanding disk and finishing by hand with a sanding blocks and a lot of elbow grease. The next issue is the damage to the edge... Im not sure if its been repaired before or if thats a steel plate delaminating from an iron core. Either way I would like to fill that with weld and reshape it. I know this can be a bit contravercial. Im a welder by trade and can keep the temps cool enough to touch (For the most part) but that brings up other issues. Ive heard of people doing this repair with mig but I prefere to stick weld it. I have heard there are some welding rods that are better for this (recommendations ?) in the end it doesnt have to be perfect or like new... If the repairs fall apart over time ill just repair it again. In theory im set up in a way that I can could rebuild it and possibly heat treat it. But for that I need to know more about what this anvil is. Iron core with a steel face, solid steel, and so on. As well as what sort of hardness I should be aiming for. I know (issues with laminate steel face to iron) this is just a thought. I want to get it to working condition on a tight budget. Not really concerned about the historical value (sorry) its a tool and I need it to work. Also I suspect its been welded before. I could use help with identifying this anvil and a basic game plan to get it into shape. Any other possible options are also welcome. The plan ive described is just how I would approch this. Perhaps there are better options. Thanks!

-

Need suggestions for heating element material

Blackcatbones replied to Blackcatbones's topic in Everything Else

What lol I had to go back and look at my reply. I never said I didnt like like the idea of H13 Steve. I think its a great suggestion. Im looking at all the possibilities to see which will work best. Theres going to be a lot of testing in that respect. Im thinking of trying som H13 just to see what it will do as a comparison to something like ceramic. -

Need suggestions for heating element material

Blackcatbones replied to Blackcatbones's topic in Everything Else

Wow this is great looks like theres a lot more possible options than I had anticipated. This could get interesting. The basic performance envelope is a blade that can glow with heat looking a bit like a blade fresh out of the forge. And can slice at temp... Not thinking of a rugged chopper. No pounding nails with it or anything. A burn of a few seconds is all it needs. Something like zirconium silicate had crossed my mind. Thanks for all the help its a lot more than I had hoped for ! -

Need suggestions for heating element material

Blackcatbones replied to Blackcatbones's topic in Everything Else

That is something new to me. I have seen harmonic, electric and thermal scalpels but not laser. -

Need suggestions for heating element material

Blackcatbones replied to Blackcatbones's topic in Everything Else

I did actually yes a while back. Saved a bunch of information on them really interesting tech. I think ill have another look at those. Thanks for the help everyone your input has given me quite a few ideas to try already ! -

Need suggestions for heating element material

Blackcatbones replied to Blackcatbones's topic in Everything Else

LoL perhaps of thats the best it can do. Perhaps just heat my coffee with it lol -

Need suggestions for heating element material

Blackcatbones replied to Blackcatbones's topic in Everything Else

Thats sort of one idea I was thinking about. Looking at high temp carbon heater coil wire. Trying to see if theres a way to perhaps incorporate it into the blade or run it inside a blade somehow... Then theres the issue of a blade material that can handle the heat. It could be that its just not possible but I would like to find out anyway. Keeps me from getting bored lol. -

Need suggestions for heating element material

Blackcatbones replied to Blackcatbones's topic in Everything Else

1200 thats not bad either. I was thinking 2200 because I was thinking that would be a good glow but really 1200 would be decent as well. BTW I see you have fenris forge. A while back I was discussing potential names for the forge. One of my top three choices was fenris forge lol. I didnt know you already had that name. -

Need suggestions for heating element material

Blackcatbones replied to Blackcatbones's topic in Everything Else

Thats a great idea! I can think of one or two such things. Ill look into that. Theres no specific material to be cut or specific thickness. Its mostly just to see if it can be done but I dont really like blades that are all look and cant perform. Considering the tall order If it can chop a cucumber in half I would be happy. -

Need suggestions for heating element material

Blackcatbones replied to Blackcatbones's topic in Everything Else

A36 thats in interesting thought. Im going to look at that a bit more. It gives me an idea or two. Im sure the heat would destroy it but... -

Need suggestions for heating element material

Blackcatbones replied to Blackcatbones's topic in Everything Else

Lmao pft. Ok. Im not really looking for metal... But it sounds like your thinking what im thinking... Nintendo lol Its only secret because its a bit embarrassing to say im even attempting it. Im expecting ill get some heat for this (pun intended) Yes its a very hot blade. Im only interested out of curiosity to see if it can be done. Im looking at carbon wire that can reach 3000F but it gets brittle. Any typical blade material would be destroyed obviously. Im thinking of ideas like a ceramic blade with carbon idk... Still has brittle factor. Then theres issue of powering it. Im used to forges and typical blade steels but this is something else. It may or may not be possible... Who knows. Ive done more things in my life people have told me couldn't be done. Its got me interested. I know its not typical of something discussed on this forum. But im reading and asking around. I figure if anybody might have a few ideas it would be other knife makers and blacksmiths. -

Im posting it in this forum because im really not sure what category this falls into. Ok... Im starting a top secret forging project on a dare from my girlfriend. What I need is a material much like that used in electric heating elements. It has to be able to reach at least 2200F rather quickly and it must be tough at that temperature. Not brittle or overly soft. And has to be somewhat shapeable. I cant say much about the project just yet but is there any such material that comes to mind ? Thanks!

-

Trying to build first forge and need some advice

Blackcatbones replied to Blackcatbones's topic in Gas Forges

Thats not a bad idea. Sort of what I have in mind. The problem is any wool liner I've found in my area is 24" x 25' Theres a heat treat company near me that seems to have the best price I've found but they want to sell me a full box 25 feet. They didnt give exact price just said a few hundred. -

Trying to build first forge and need some advice

Blackcatbones replied to Blackcatbones's topic in Gas Forges

Thank you all for the information in my first post. I am still deep in research. It seems like there are several ways of doing everything and just when ive decided on one way I change my mind. I want to get get going with this build I think ive been testing the water for too long. To start im in BC Canada so I would love to hear from anybody in my part of the world that has experience or links to resources. Ive found it can be difficult to find materials and such. Other than highscool im pretty new to forging. I have pretty much got my forge all designed now im just trying to settle on a few last details. I want to reach welding temperature 2300 with room to spare. I took some measurements of the largest piece I will be forging. The inner area of the forge needs to be at least 11 inches wide by 4 tall. So I'm settling on an 11 wide by 12 long forge. I believe the volume is around 1400 cubic inches. Open front small opening at rear with firebrick front and back to change the openings as needed. I was thinking freon or propane bottle but its probably easier for me to just get some thin steel tube in my situation. If I go with ITC-100 and spray it on. What sort of sprayer will work for this and how much IR coating do I need for a forge of this size. I have heard 1pint of ITC-100 will be enough if sprayed is that correct ? I know that soft thermal bricks are usually used and they crack easily and hard brick is a heat-sink. What I cant find is how much either factor is an issue. If I use hard thermal brick for front and back of forge and forge floor will it work... Explode... Melt down... Or just take a bit longer to heat up ? These seem to be the best options for brick that ive found but I cant decide... Just too many choices. Could somebody help me narrow it down. http://www.euclids.com/index.php?cat_id=160 http://www.baileypottery.com/kilns/kilnmaterials.htm How much rigidizer, refractory mortar will I need. Ive been reading that satanite is used as the refractory mortar. I want to make this layer thick like half inch or so... Will any refractory mortar work and where can I fond some in my area ? There is some listed on the euclids site but im not sure if its what I need or what quantity. For ITC-100 This seems to be the best option in my area: http://www.tuckerspottery.com/tkps/index.php?page=shop.product_details&flypage=flypage.tpl&product_id=1302&category_id=152&option=com_virtuemart&Itemid=1&vmcchk=1&Itemid=1 Automatic temperature control ive found these: http://auberins.com/index.php?main_page=product_info&cPath=3&products_id=39 http://auberins.com/index.php?main_page=product_info&cPath=1&products_id=14 To make the temperature control for these automatic do I need any other hardware ? Can anybody tell me if the links ove found have a good rep or no ? Ive been ripped off once or twice ordering online... Tends to make a person paranoid lol Ive been reading so much... Countless hours the information i find has been repeating the same stuff for a long time. What few questions I have left are things I just cant seem to find answers too. Im sure more questions to come im a bit of an airhead please let me know if theres anything I may have overlooked. Thanks again ! -

Trying to build first forge and need some advice

Blackcatbones replied to Blackcatbones's topic in Gas Forges

Thanks this all helps a lot ! The plan is coming along rather well. I was going with a 24" length because thats the width of most of the wool ive found. Im going to cut that in half now. I may go with a 12x12 interior work area or something like that. Bound to change agan im sure. -

I have been researching for a long time and I am just about ready to build. Im thinking of a pretty basic horizontal forge. With Kaowool liner, rigidizer, satanite, ITC-100 and bubble alumina for the floor. Useing Reil burners. Firebrick wall for front and a small opening with firebrick at back. Dimentions 24"deep and 10"diameter plus 2-3" for the liner. This is for small projects, knives and such. I am trying to reach welding temperature with this. Does this design sound about right ? Im trying to find a balance between size and efficency. I might want to do one or two projects that are a bit wide like the head of an axe. So 12" inner working diameter would be better. I just dont know how this would effect the efficiency. I am also having a VERY difficult time tracking down the refractory materials where I live in Canada. What I do find is usually three times the reasonable cost. I could use some help here. The Kaowool I have found comes in a box its 1" thick by 24" wide by 25' long for a few hundred dollars. I cant find anything on layering the wool to make 2-3 inches from a one inch sheet. Can it be done and is there any trick to it ? I saw read someplace that a three inch thick liner is best but most people seem to use two inches. Cost being a factor... Is three inches thick that much better or will two work fine ? With regular dayly use how often should I expect to have to replace the full liner ? (Again a cost thing) My last question is. I noticed there are quite a few types of firebrick. Im looking for the best insulating brick I can get. Which one should I be looking at ? This is also my first post at this great forum ! Thanks for your time !