-

Posts

24 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Krimble

-

-

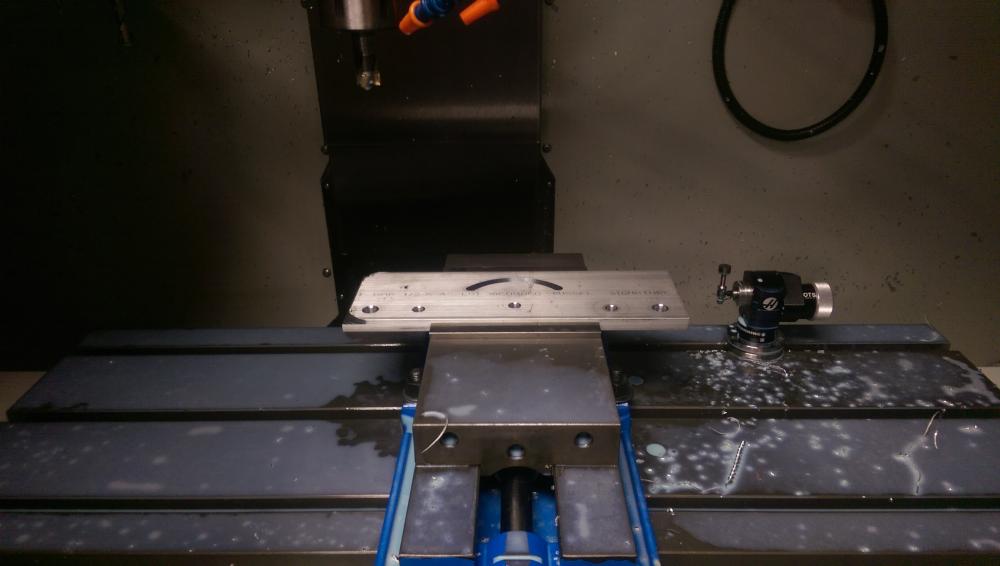

I've been working on my own grinder for a week or so now, following Dan Comeau's BG272 plans. If I would of had more time with a CNC mill I would of built a KMG clone, but ohh well.

I have one question. Due to my budget, I had to get the only used motor I could find locally. A 3HP US Motors. The only downside is that the shaft is 1-1/8" and no one sells a drive wheel with that bore.

Unfortunately I do not have the stock to turn a wheel this size on the lathe. Any recommendations on how to get a drive wheel fitted on the 1-1/8" shaft? Thank you.

Here's some progress.

-

Nice man! I did something real similar with a 55 gallon drum and a brake drum. Looks real nice. :)

-

-

Anytime Krimble....send me a PM and we'll hook something up!

Allright! Thanks a lot Darren, I'm sure it will be around the summer, if that's allright with you. By the way, I don't think I told you, but my name is Samuel. :D

-

WOW! I was almost done building my current forge, but I think I will strip down my old broken mower and do this, it's exactly the style I was looking for!

Nice job, and thanks!

-

Nice knife Darren, When I get to know my blacksmithing terms and what not, It would be cool to check out your shop. I am about 2 hours away I believe.

-

Thanks for the explanation Glenn, also thanks for the great idea Ridgeway! I will try to make the drum forge work tonight. I will post later or tomorrow with results. :D

-

Hey guys, the other day I made a small forge, but it was too deep, and did not have a big enough diameter. It did burn good tough, I was not paying enough attention, and I accidentally melted a piece of rebar.

So I made a new forge, wich was this, but it does not really work well. The wood was too close to the forge and it burns a little, and the coal is not deep enough. The table is nice though, but If I ever do another design, I will patch it up and use it to put tools and other miscellaneous things on it.

I looked at Glenn's 55 gallon forge blueprint, and heard good thing about it, I have a smaller drum, but I have a feeling that it would be better than my other forges. What do you guys think would be better?

I really appreciate any help I can get, because I want to finish up the forge and worry abut the tools and anvils after.

I might also ask a local blacksmith, there's going to be a demo next Sunday. Can't wait! :D -

Yeah, like Modvitner said, real nice forge!

-

Hi guys, I got myself a place in my yard for my forge, and I made a new table.

The table is made from wood and the forge part itself is made out of a rim. I wanted to cover the holes in the rim with metal sheets.

I have a feeling that the wood will catch on fire, because there is wood inside the 55 gallon drum.

Does anyone have any ideas on what I could do? Thanks! :D I know the shed is crap, but my dad gave it for free, and I will fix it up.

-

You can have a forge inside a shed (either coal or gas) as long as you have sufficient ventilation. A coal forge should have a chiminey (side draft seems to work best), which could go out a window. A fan in a window with a door cracked open should provide enough cross ventilation for a gas forge. Use a carbon monoxide detector to ensure you have enough ventilation.

Really? I might ask my dad, I haven't really tought too much about it, but maybe if I move the shed little, so if it burns, well... it wont be next to the garage. -

Looks real nice, I wish I had an inside forge, I have a shed, but that's not really safe, so I can't really forge in he winter. :(

-

Very nice start! We want to see pictures of your anvil too :)

He said he had to use it for a couple months, but after that, the anvil is mine :D -

Congrats, great story and lesson for us all, if we do not pass down the tools then why pass down the knowledge? BTW, I hope once you are up and running you have him over (that was a cleverly hidden hint)

I sure will, I have many things to learn, but like he said, I have a lot of time to learn it. He used it to make anchors and stuff for his boat, because he used to fish lobster.

He said that back then there was not much welders and they weren't cheap, so they welded with a forge. He then told us many stories about blacksmiths and god and stuff, but it was interesting. -

Hey guys, Me and my grandpa went to visit a older guy's forge for ideas on how to build mine, but it ended up of him saying that he was looking for someone to buy it, because he was getting old.

I asked how much he would want for it, and to my surprise, he said that because I was young (17 years old) He would sell it to me for 25$, because there is not enough blacksmiths these days, and It would be an investment. So we went to get the trailer and we picked up the stuff.

I noticed that the table was wooden and covered in cement, so tomorrow I will rebuild the table and put some bricks instead.

The reason I find 25$ a steal, is because I have a very good working, Canadian Blower & Forge Company blower, two pairs of tongs, wich I needed, a 100 pound anvil I will get soon. ,a small fire pot that's on the table, and a cool Canadian Blower & Forge Company Hand drill press in mind shape.

Heres some pics :

(Sorry for the quality, It was dark outside. )

-

I tried my Forge with some leftover coal today with my friend, and I put a piece of rebar that the tip was flattened for a couple minutes and like 2 inches of the rebar just melted off.

But I will start building a 55 gallon forge tomorrow, so I may start a new build thread Cheers! -

I bought two 50 lb bags of smithing charcoal near Boston, and I tried it tonight, it gets really hot, but I have to re-make a forge, I think I will make the 55 gallon drum one.

Here is some pictures.

-

Well I live in Canada, and I'm going to the states tomorrow. In New England Mass to be exact.

Coal is rare and EXPENSIVE around here. I would like to know if this Coal is good, because I might stock a bunch of bags if yes.

http://hand-tools.ha...oal-101755.aspx

thanks guys! -

Hi guys, this is my first post, even tough I was here for a couple days meeting a couple people on the chatroom and by message.

I finnaly got some charcoal for my forge today, it's briquets, but I have heard that they still bring metal red, but a little less than coal.

I started it up with a little gas and some oil on the charcoal and once all corners we're gray I turned on my fan.

I stayed my steel in the coal for 10-15 minutes and it did not get near turning red, any ideas?

It's like the drum is not deep enough so there is not much charcoal that can get on top, and when the fan is on all the charcoal is pushed out from the hole in the middle, so it does not get enough air on the charcoal.

Thanks a ton guys!

Here is my prototype : Keep in mind that the fan is not connected in the pictures.

The fan I have is a small radial fan like this. http://www.ventilati...es/cat/89_b.jpg

DIY 2x72 grinder

in Grinders, Sanders, etc

Posted

I can bore it, but my only access to machine tools is at my college and this is my last week until graduation. I do have a job lined up, but it might not be a good idea asking to use a lathe or a mill when I'm just starting out there. I think that since I haven't bought wheels yet, my best bet is to make some sort of adapter this week while I can. Thanks for the tip.

Most likely something like this, but with a keyed shaft.