GobblerForge

-

Posts

229 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by GobblerForge

-

-

I've used the vertical hole method with two variations. One uses a hole drilled in the hearth and a hole drilled deep into the lentil, as recommended earlier. The other used a hole drilled into a plate. The plate was then pinned to the hearth with rivets for pins. Gravity does the rest. The one problem I have with anchors that put internal pressure on the hole sides is they can and have broken masonry. Stone compresses great but fails with tension.

Gobbler -

Make the broach out of file steel and then harden in bacon grease. No tempering required. I've made lots of them this way and not a one has broken. Perhaps the side worn toward the body could be the strike surface and not mar the show side.

Gobbler -

I have noted over the years that forging on rainy days, when the humidity is in the 90's, that I have more difficulty getting the fire as hot. I attribute this to there being more water in the fire, thus cooling. On dry days it's a little easier to forge and work the fire. On a related note, my shoulders hurt more when I work on a rainy days as well.

Gobbler -

-

Localised heat and bent by hand I would think.

Gobbler -

Im not sure about cutting it but I have seen first hand a "C" frame punch that used rifle casings as power to punch holes for the tie plates, You put the blank in and smacked it with your hammer... and BANG you got a bolt hole....

I have a box of those cartridges in my collection. I would like to see the tool that does this job. Sounds frightening. I've only seen drawings of it..

Gobbler -

Just a thought, but I would consider finding out what some of these old tractor parts are worth to the tractor collecting community. You may find that selling the parts to a collector or dealer may make more money and will buy more stock than the tractor produces.

Gobbler -

When the gallery gets running again, look in Gobblerforge gallery. I used hydraulic parts to build my tire hammer.

Gobbler -

I made my apron 18 years ago out of a deer hide. No problems yet.

Gobbler -

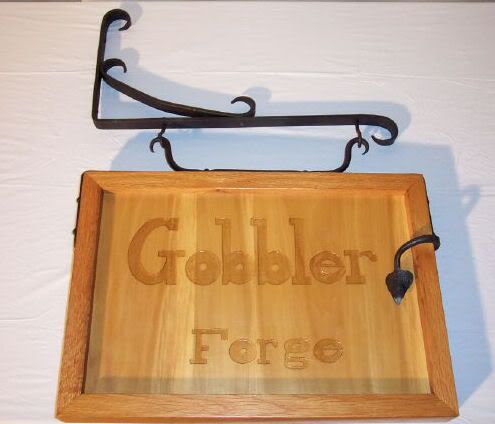

Good job, a little technical guidance for anyone hanging a swinging sign. I note yours has the hangers facing in the same direction.

The suspension hooks on the support bar should face in opposite directions so that if a gust of wind causes the sign to swing high, it will only disengage one of the mountings and not allow the sign to become totaly detached and a safety risk if anyone is in close proximity to where it may land.

My hooks actually swivel. The lady that took the photos positioned them to her liking for the pic.

Gobbler -

I tend to hang my horse shoes at an angle so a little luck spills into the shop.

Here's my signs. The wood sign is portable to hang at demos.

Gobbler

-

-

-

As Ironstein said, wrapping a chain around the waist of the anvil a time or two will absorb vibrations. Don't over tighten the chain. It works better if lose. In the pic you can see I use the lower chain to hold the anvil to the stump and the upper chain to quiet the anvil. When people ask why, I tell them it's just a mean anvil and I have to hold it back.

Gobbler -

150lbs. With stump, chain and tools, right about 200.

Gobbler -

#200984 dated to 1913 per AIA.

Gobbler

-

What is the issue with pouring lead?

Gobbler -

WD40 won't hurt anything. Any oil is good. Some are just better.

Gobbler -

I could be wrong, but I'm pretty sure that except for the really early HB's they were a forged steel top half, and a forged wrought iron bottom half, joined at the waist. The early ones had just a steel face plate and a wrought body.

You are correct. I meant forged steel, not cast steel. I don't know what I was thinking there. -

On this particular anvil I suspect you will find the weld line about mid-waist. It should be all cast steel the entire top half of the anvil. HB started doing this in about fall 1908. They were experimenting with different methods at that point in time so I would expect to find different examples.

Gobbler -

Condratulations, Grampaw. That is as cool as it gets.

Gobbler -

If we can get the serial number, it can be dated. If it is a HB and has the center weld line, then it is most likely 1909 or after.

Gobbler -

He didn't say edge. He said the whole bottom was wore flat. By what? Wouldn't it have to be on something moving for a long time to wear flat? I just don't get it. I've seen hundreds of anvils, same as a lot of folks here, but never saw one where the bottom was worn. Only the top.

Gobbler -

I guess, your welcome. I just finished two back to back three day demos. One at Atwood Lake Fall Festival and Algonquin Mill Fall Festival. I love showing and teaching. That's why many of us do what we do. Making a little cash never hurts to inspire more work but the demo is the real reason. Ohio's fall colors don't hurt either.

Gobbler

what is it??

in Blacksmithing, General Discussion

Posted

They are also used on grader blades called scarifiers. The tips are carbide and can not be forged. If they are brazed on then they will come off when you heat them in the forge. I tried. The steel is some pretty good steel. I don't know what.

Gobbler