-

Posts

24 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by pierosoleil

-

-

-

thanks for the info/suggestions... i wasn't aware that Little Giant made these. Upon investigating i see that they have the bolts on the sides, heads facing towards the "outside". I was thinking having them in the body of the dovetail, thus fastening thru the dovetail itself, the threads being in the die. My drive is that i have a length of S7 steel, plenty for making a few dies, but not quite thick enough. If i could bolt on a dovetail onto these then i'll be OK. The hammer i bought this past spring in missing its dies and the sow block. What do you fellows opine; for the sow block... should i build one up using thick bolted-up steel plate sections (standing vertically), or have one cast and machined (more expensive). Do i need any "special" steel if i go with the build up option ? (BTW; it's so great to have this forum, where one can find a "big brother" to help around and make intelligent suggestions.... thanks-a-million ! )

-

is there anything "wrong" with designing/building a two piece die; with the dovetail part bolted to the striking part of the die ?? Seems to me the hardest and thus more expensive part to machine is the dovetail section... Then the striking section could be a "chunk of metal" found at local steel pile/store/ebay/junk and then drilled, tapped and assembled to the dovetail. Or am i missing something.... ??

-

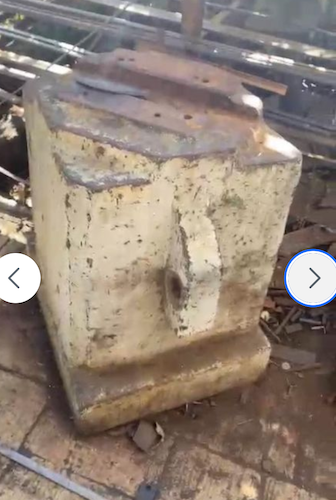

Well folks... it's now sitting outside my shop. I don't plan moving it up north, as Mexico is where i spend my winters. I'll send more pics of it later on today or tomorrow... BTW; i've never had problems (thru the 20+ years i've been coming here) at the customs, either bringing old stuff in, or out !! I always declare everything as used and/or for parts... and that included fly presses, forges, anvils/swage block... you name it ! The electricity here is 127 V, 60 Hz... and the motor on that gem is a 2.5 HP Siemens, 3 Ph. The hammer is in PERECT conditions... with original paint, nothing loose nor tight, and no discernable wear !! It was owned by an amateur german smith till he passed away 18 yrs ago, and then forgotten about in a corner of his "taller", under a ton of detritus. It was pure serendipity that i was scootering by there (in a corner of the city i never go thru !!), and noticed the top linkage while the garage door was opened. Bought it on the spot (in caliente is how they say it ! ;-) ) for the grand sum of $750 !!

The only thing missing are the dies... more on that later. (i'm still hoping that they are "discovered"..) Anybody else on the forum has a hammer like this one, or have any info ???

The only thing missing are the dies... more on that later. (i'm still hoping that they are "discovered"..) Anybody else on the forum has a hammer like this one, or have any info ???

-

Hi... I'm working out the delivery logistics... and it should be in my shop this week-end ! So you can vision the movie.. i was just trying to post a windows compatible one.

Sorry... i meant the dies. ( And that anvil you see in the background... has been beaten to death for the better part of the last century ;-) )

Anybody else on the forum has a hammer like this one ??

-

Hi... I'm working out the delivery logistics... and it should be in my shop this week-end ! So you can vision the movie.. i was just trying to post a windows compatible one.

Sorry... i meant the dies. ( And that anvil you see in the background... has been beaten to death for the better part of the last century ;-) )

Anybody else on the forum has a hammer like this one ??

-

-

ever since i've seen this press.... i've been wondering about making a powered fly press out of it.

It would be a nice project to try... as most of the "stuff" is already provided. (ie: that big flywheel has nice surfaces for the "add-ons"..... )

Hmmmm.. -

there's this cherry deal on ebay: http://cgi.ebay.com/WATERBURY-FARREL-Screw-Press-Fly-Press-20-TON-/150487543488?pt=LH_DefaultDomain_0&hash=item2309c1aec0

i have a smaller Farrel fly press, and think highly of it . Now.. here's it's big brother !! -

... it says "enclume de cloutier" : which translate to "anvil for a 'nail-maker' ....

nifty little one !! -

My location... ??

Well.. i'm from northern Ontario, living in southern Ontario/Quebec on the summertimes, staying with my sweet~gal in

Upper-Peninsula (Mi) in autumns and springs, and my home is in Cuernavaca, Mexico (although i only have "tourist"

permit down there.. ! )

I was searching for a smaller hammer for my shop in Mx, but i'm now considering setting this one up here in the UP !??

Sometimes other "things" than forges can be "hot" enough to gravitate around.....

And... i like your advice Bob; What do you suggest after the Beaudry, and then the Ironkiss, and the ( ?? ) There ain't

much work up here in Mi, but then again there's lot's of free time... and good olde scrap iron from wayyyy back ! -

Yeahhh... i like this hammer, even though it's slightly on the heavy side of what i was looking for.

I guess i'm just reluctant to break the new floor of my shop to pour a heftier foundation for it, plus

it will kinda take lots of precious floor space.... !! And i wonder how precise/delicate it's "touch" will

be for smaller stuff....

The price ($4K) is OK, since so little seems to be needed to get it running right. But then, by the time

i add all the work (concrete, floor plate, A-frame, electrics (just found out that it's a 575V 3-phase),

transportation,etc) it's going to cost me closer to $7K. In the range of a smaller Ironkiss.... but that's

not the same machine. I like mechanicals.....

I saw pics of Kevin's hammer, and it's a Bradley. Same design, but different company. And smaller...

I'll try to contact him anyway...

I was hoping to find someone with such a hammer to stop buy and look and talk about in December,

when i'll drive down to Mexico.

I'll send pics of it as soon as i can..... -

nope... you've never heard of me !! That's 'cause i'm a newbie.... One that really glad to have found you folks. I'm

just about to lay my hands onto this orphan.... but i'd like the opinion of the sages (yer guys, around the round table)

before i commit myself. Searched "lo and behold"... and never found anyone, nor any website, that owns/refers to it.

So... whatdayathink.... ????? (250#, circa 1897, disassembled but cautiously stored, complete with 10hp motor and

jackshaft... just as shown in the photo (but less the A frame for the jackshaft))

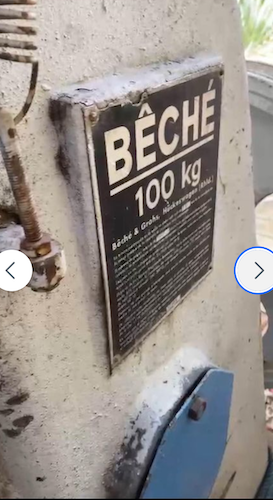

Bêche 100kg.... to be rescued !

in Power Hammers, Treadle Hammers, Olivers

Posted

I was probably imprecise in my communication; this is not for me, as i already have my hands very full ! I thought that it might interest somebody else, not afraid of a "challenge" !! I don't think it would be that difficult to put it in a container in the nearby port of Veracruz and ship it.... this is done very often by Europeans, as by USA folks who buy older cars here for restoration. All depends on how one values what he finds... I'd be willing to be a link between the seller and the buyer... just to see this machine working again as it was intended !

Also closeby these friction presses showed up....;