MadsRC

Members-

Posts

25 -

Joined

-

Last visited

Contact Methods

-

Website URL

https://www.v42.dk

Profile Information

-

Gender

Not Telling

-

Location

Denmark

-

Interests

Blacksmithing, bladesmithing, old-school projects, IT security, programming, woodworking.

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

I'm looking to forge myself a few wedges for splitting wood, but I find it rather hard finding any material on what type of steel was/is used to forge them? I would think that some kind of soft steel would be used? Maybe even mild steel - As the steel would need to be harder than the wooden log, but softer than the tool striking it (and then the fact that I know wedges are consumables). Having a hardened wedge would, as with having a hardened poll, increase the chance of the metal fracturing and throwing chips in all directions (Please correct me if I'm wrong?) So I should either use mild steel (and reforge them when the get too deform) or maybe use a hardened steel forgewelded to a softer striking surface?

-

Ah Jeremy, would you happen to be the author of the original thread where the pictures originates from? If so, do you happen to know what happened to the thread?

- 13 replies

-

- charcoal forge

- brick forge

-

(and 1 more)

Tagged with:

-

My first real attempt at making something creative at the forge. Forged from a piece of coil spring (Ø15mm) in my charcoal forge. There's a few doodles on the paper for some scales and for some retouching. The monkey tail is a tad too large, thinking of either forging or filing it smaller (like on the drawing) - Also contemplating wether or not I should redo the shoulder so that the head/back is inline with the shank. Could file it, though the twist could cause troubles... Might have to reheat it in the forge (or maybe a torch...)

-

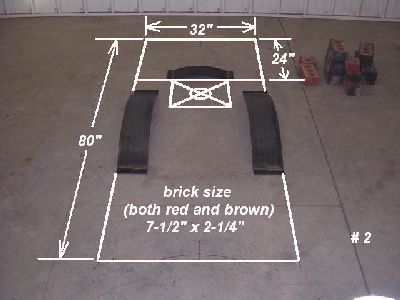

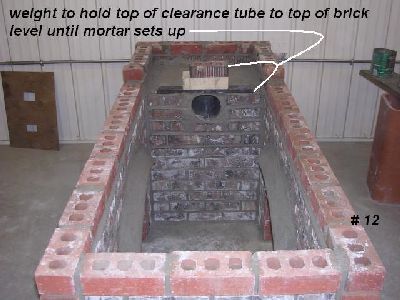

I'm in the process of designing (and eventually building...) a brick forge. During my research I came upon a non-existing thread (Google indexed and links to it here, but it doesn't seem to exist) that detailed a brick forge build. I managed to source the pictures elsewhere and I've attached them below. Hopefully you can use them. IForgeIron Blueprints Copyright 2002 - 2011 IFORGEIRON, All rights reserved BP0553 Building a Brick Forge - Part 1 by Jeremy Knippel 2006

- 13 replies

-

- charcoal forge

- brick forge

-

(and 1 more)

Tagged with:

-

Actually found this while researching. Seems like soapstone crayons will still be visible up to 2000C

-

I was wondering how people mark steel when they are working it? Using a pencil or marker doesn't work as it's burned away. Scratching the metal doesn't seem to work, as I can't see the scratches on the hot steel. The only thing I've found that works is punching a small denty, however, this isn't pretty, and won't work for longer lines. Measuring doesn't really do any good when you can't mark What do you use, and what did the people of old use?

-

I'll admit that I haven't been around a stick welder for nearly a century. So I'll need to go fetch one... What sort of amps will be needed? Would 150 be enough?

-

This thing is old, indeed. Right now I'm only using it for it's Hardy hole (As you mentioned). I'll see if I can get a few pictures of the sides and the bottom. Could you elaborate what you mean with wrong configuration? Never heard of the Gunter method, but I'm xxxx happy to hear you and Frosty mention it. I'm all for restoring old stuff, so I won't worry about the time it takes. Guess I'll read up on the Gunter method

-

That looks like a decapitated starfish

-

Charcoal burning green

MadsRC replied to MadsRC's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

I do plan to give them a call tomorrow. Surely, colored fire is caused by chemicals. If there's a chance their harmful, they should be recalled. Already put the bag aside for later. You're right, hopefully it's not CCA. I did some research and found quite a few chemicals that can cause green flames: thallium compounds antimony compounds barium compounds manganese(II) compounds molybdenum compounds ammonium compounds phosphates moistened with sulfuric acid borax copper sulfate boric acid Ref: http://chemistry.about.com/od/firecombustionchemistry/fl/What-Chemical-Turns-Fire-Green.htm -

So, I found an used anvil, took a chance with it. I'm not sure what brand it is. It's sourced in southern scandinavia. I think it forged, as I can't find any molding seams and it has several strategically placed holes in the base and sides for tongs. Weight is about 75kg. The pritchel hole at the horn seems like it's blocked. Might just be gunk, there a slightly smaller hole below the horn. I think that someone once tried to fix the face by welding a plate to it (or just weld the face). The did a poor job, as it's starting to look like a teenagers face... It's uneven and full of spots. On one of the pictures, you'll see a large portion of it broken of. Tried to sand it down, but I would need to remove about 8mm for it to be leveled. What do you guys think? Worth saving, brand and maker? Note: I wrote this on my phone. When I get near a pc, I'll clean up the post.

-

Charcoal burning green

MadsRC replied to MadsRC's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

Never actually considered that. If CCA smuk info the batch, that would be bad :S So much for "restaurant quality" charcoal -

So I fired up my forge with a fresh batch of charcoal the other day. After some time, I noticed that some of the flames had a slight hint of green. It was fairly obvious, as it was after dark, so I'm fairly sure I that I really did see a green flame. I know that some chemicals can cause green flames (I think I've heard that Borax can cause green flames). Is charcoal supposed to give off that color, or is it an indication of bad quality charcoal?

-

Charcoal vs Coal

MadsRC replied to Ten Hammers's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

Wohoo! I knew I wasn't providing enough data I'm not sure about what type of coke it is - The site says "petrocoke", so I guess it's petroleum coke? I'll contact the manufacturer and ask. Currently I'm using a double-chambered bellows and a 3/4inch sideblast tuyere in a clay forge (Similar to Charles' Box 'o dirt) - However I plan to use a 90w blower, but I don't have any power in my forge yet, and won't for a few months atleast. Currently I'm forging small stuff. Trying to forge tongs, forging nails, hinges etc - or atleast, I'm trying to. Eventually I'd like to forge blades and hatches. -

Charcoal vs Coal

MadsRC replied to Ten Hammers's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

Currently I'm forging with charcoal, but I was wondering if coke would be more efficient (burn hotter?) I'm able to get 25kg of coke for about 8usd just across the border (which is a lot cheaper than charcoal). The coke consists of < 0.7% ash, max 9%water and max 1.05% sulfur. The coke size is 30mm-60mm/90mm Would it work? And how much different is coke to forge with?