-

Posts

15 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Josh.Sampson

-

-

On 3/23/2022 at 1:20 PM, anvil said:

correct, center of width, not length.

This is geared toward things like hammers, horseshoes, finding center on things between 4” (pretty easy to eyeball) and 20ish” quickly. Just an idea I had and brought to life. I too have used many methods of finding center of length.

I keep a 3’ steel folding rule in my back pocket all day every day. Love it.

-

On 3/20/2022 at 1:22 PM, anvil said:

nice tool, nice design. Should hold up forever. I wouldn't make a center punch out of the bottom rivet, I'd do a scribe instead. That way you could mark your center line along a whole bar.

I have a far simpler solution. It may be what Thomas is talking about, not sure. I'll see if i can get a pic of it. Its 3 pieces with 2 legs riveted to the ends of the third one. Then drill a small hole dead center between the two rivets for your scribe tip to fit thru in the center of the middle piece (centered length and width). The outer legs will pivot and fit flush and parallel with the two sides of your flat bar. The hole in the middle bar is always on the center line of any sized stock as long as the legs are parallel with each other and your drilled hole is centered. Dirt simple for a blacksmith to make and use..

The length of the cross bar determines the max sized stock you can use and it will work on any sized stock smaller than this.

The length of the cross bar determines the max sized stock you can use and it will work on any sized stock smaller than this.

From what I’m picturing, I can’t imagine this one tool working well with a variety of lengths and cross sections. Say you have a piece of 3/8x3/4 at 12.75” long and a piece 1/2” square at 6” long. If you had just one of the tools you speak of, would it work on both of these? If so, I need pictures because what I’m picturing would not.

-

3 hours ago, ThomasPowers said:

You saw my post about making a center finder from 1 short bar and 3 posts?

Yes. From what I picture from your description, I’d imagine it would only work on fairly wide stock or you would need a few different sizes of the tool. I could be misinterpreting. Do you have a picture of one?

-

9 hours ago, Frazer said:

I'd be interested to hear if the rivet tightens up over time and locks up the movement.

Regardless: 1. Even if it does that's an easy fix 2. I really like the idea and 3. That's some very clean forge work.

Time will tell. I think since it is hardened it will take a while to cinch up. We shall see. Thanks for the compliments.

-

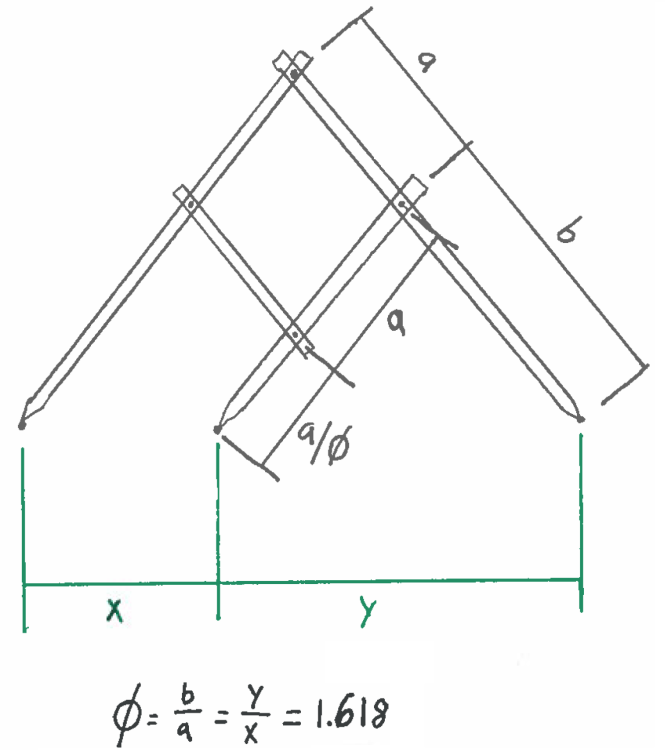

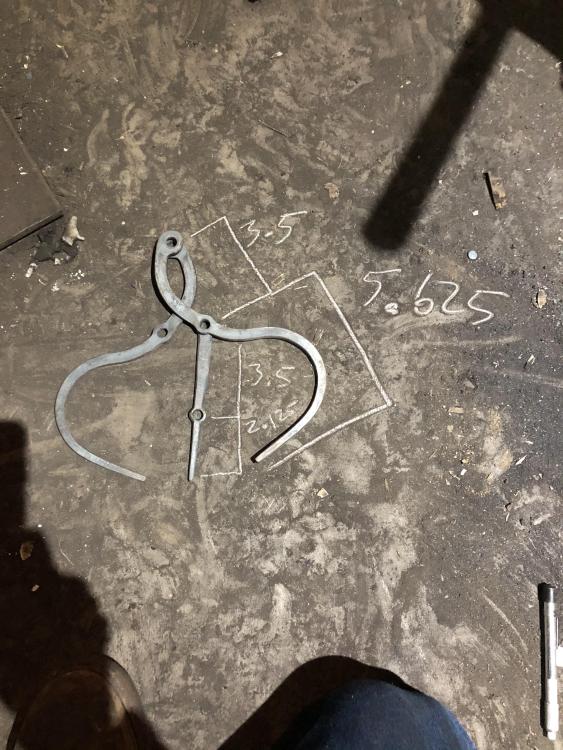

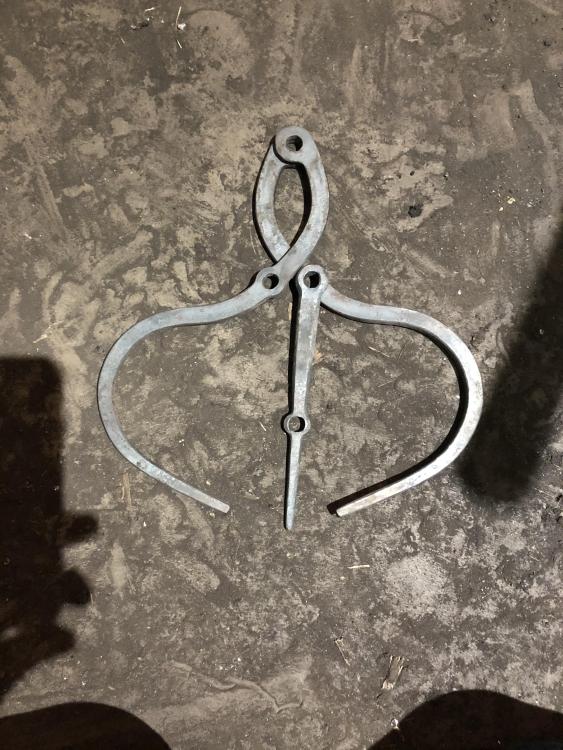

I had the idea of making a pair of callipers similar to the Golden Mean callipers I forged but to measure the halfway point instead. When working out the numbers, I realized the center point would be dead center of the bottom rivet.

I had the idea to make the bottom rivet of tool steel (Atlantic 33 in this case) and make a center punch of the rivet. It works well though I would make the tool steel rivet differently next time. I think this will prove to be a handy tool.

Sorry I didn’t get progress pics this time but the process is nearly identical to the Golden Mean process I documented in an earlier post. But I did get a video showing how well it works. Hope you enjoy.

-

On 3/14/2022 at 6:35 PM, Frazer said:

Very nice! You can definitely do some fine tuning with it cold.

On 3/14/2022 at 9:14 PM, Goods said:Josh, how about cutting the center marker at the rivet. Then have a punch with slots riveted in between the pivot joints. That way the punch is always centered, but can slide in and out to mark central easily on a wide range of widths. Could take a couple different versions/tries to make it work…

Did you make it to Kevin’s last weekend? I had other commitments…

David

I started on the center punch style at Kevin’s. Just finished them up last night at Steve King’s. I’ll send you some pics and maybe post some here. The sliding center pointer idea did come up but I like that I can mark the center easily with them.

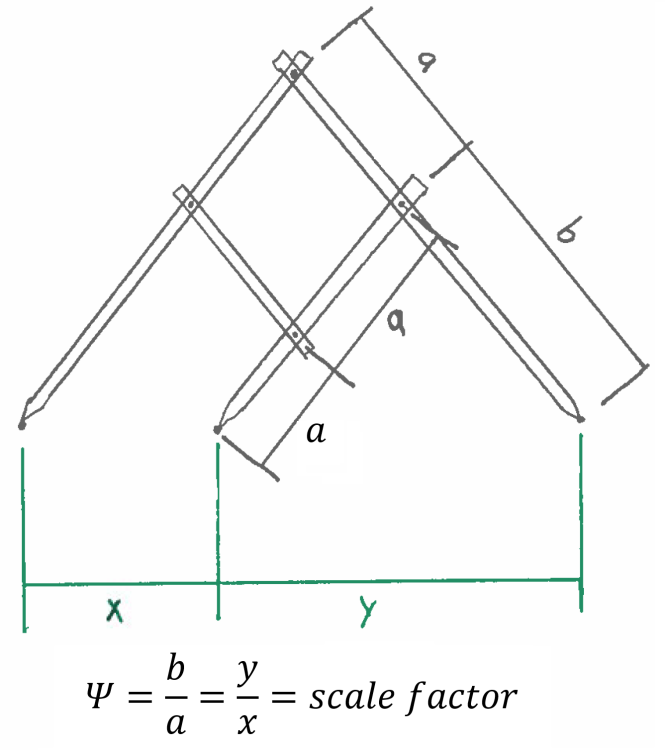

On 3/16/2022 at 2:53 PM, Frazer said:For folks who aren't confident that they can forge this style a pair of golden means calipers, they can be made with flat stock and minimal forging. The measurements given in Josh's picture 7th from the bottom are all you really need and can serve as a reference. They can also be changed as long as you follow the proper ratio. I made a doodle that may help.

The ratio can be changed to something else (1:2 for example) as follows:

Granted you could also make a set of X shaped proportional dividers if you want to divide into 3rds, quarters, etc. with the same tool... but that's less fun.

Correct. You can change the ratio to anything you want and the bends are mostly aesthetic. The most important part is all of the ratios working out correctly. I’m going to post a center punch pair I just finished up.

-

On 2/23/2022 at 9:20 AM, Ridgeway Forge Studio said:

That is some top level work. And the precision involved is beyond my understanding. Kudos for the good work and thank you for the process photos- this would make a great blueprint.

Thanks you very much. I just started another pair but instead of the Golden Mean they will measure the center point. The center will be in the middle of the lowest rivet so I plan on making that rivet from tool steel and leaving enough on one side for a point to use as a Center punch. I’ll post pics when I finish them. Haven’t done good on progress pics with them though.

-

17 hours ago, Goods said:

Josh, that looks great.

David

That looks great! Did you get your power hammer yet? I’ll probably bring them to Kenny's. I’ll have to keep them off the iron in the hat table.

-

-

-

1 hour ago, Chimaera said:

Josh- wonderful job! I’m very impressed by how symmetrical you got the pieces. It looks like some kind of calipers, maybe? But then what’s that center piece?

They are Golden Means Calipers. There’s one more piece that will link the pointer in the middle to the other caliper half. They will show the proportions of the Golden Ratio or Golden Means which is everywhere in nature. It’s a very interesting phenomenon. I will post progress pics and the finished product when I finish it up.

-

I was sad to see a lot of his videos gone. There were a lot of good references.

-

-

Are you located in Indiana? I’m a member of the IBA and would love to see this thing sometime.

What did you do in the shop today?

in Blacksmithing, General Discussion

Posted

I remember making leaves just like that at first. It’s a good start. Almost 2 years in now and everything’s looking a lot better. Everyone starts where you are. You have a lot to look forward to.

Here’s the last couple things I’ve made. Working on a gravy ladle to go with the flesh fork now. Everything is hammer finished.