-

Posts

13 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Charlycuervo

-

-

6 hours ago, pnut said:

Will you be using coal or charcoal?

Pnut, for the first attempts I will use charcoal, it is cheaper and easier to buy here. I have a coke supplier a couple of miles near my house, but I don't know if it's suitable for forging steel.

-

BIGGUNDOCTOR - Argentina is a beautiful country, I came for vacations and stayed 36 years...

-

14 minutes ago, BIGGUNDOCTOR said:

Curious, how much smithing is still done in South America? We have members from all over, but very few from Mexico , Central America, and South America..

Thanks BIGGUNDOCTOR, I'll look for JABOD forge. I got the drum with a friend who has a lot of old car parts, in fact every so often I go to see him looking for something useful for my projects, I like to make my own tools and machines whenever I can. I don't know wich car it's from, the new ones don't have drums.

About your question, I can say that there are many blacksmiths in Argentina and Uruguay, most of them making knives. The big issue with almost all of them is that they don't speak english. Many of them are country people, where schools do not teach another language than Spanish.

-

1 hour ago, pnut said:

If you make another you might want to consider lining the bottom of the brake drum to bring the floor up to the level of the piece in the middle. You might need to cut the sides down as the drum looks a little deep. Keep us posted.

Do you think it's deep? I had not thought about it, it's about 2" deep. Any suggestion is welcome, thanks.

-

Sunny winter's sunday at Buenos Aires, I've started to make my brake drum forge.

The only brake drum I could get has that piece in the center that took me a long time to remove, even with a heavy duty grinder disc in my 7" angle grinder.

I also made the bracket (it's the right term?) for the blower, I plan to use an old hair dryer for that. Since I'm not a good welder, it took me some work and a lot of curses to do it.

Finally, I got that piece of an old wash machine that I planned use as a table for my forge. It's enameled and I know that with heat it goes to break and jump everywhere so I think to cover it with refractarian tiles to avoid that issue. What do you think?

-

Hi, the story behind my nick...

My real name is Carlos Godoy, my friends call me Charly el cuervo (raven).

Cuervo is for two reasons: the soccer team I like is known as "Los Cuervos" so the fans of they are knowed as "cuervos" and the second reason comes from a jilted lady who sayd about me "this guy is really like a raven".

So "Charly el cuervo" becomes Charlycuervo. -

Thank you all for your welcome, I hope to learn a lot from you in this forum.

I have started reading some posts to learn while I recover from the covid.

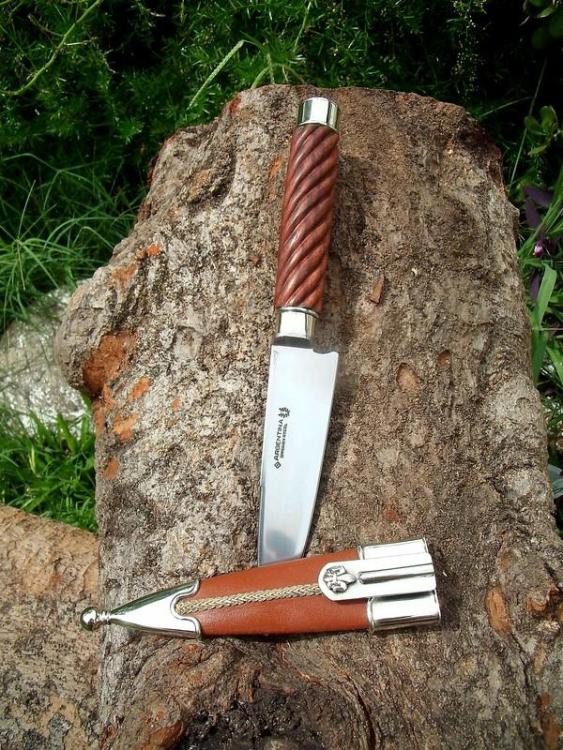

Thomas, if you talk about that brown sheat, I wanted that leather stitching stay in sight, that type of stitching is highly appreciated by people from the countryside.

About Kemal knives: wow !! I still have a lot to learn. I have various chemicals for that but I am not yet learned how to use them.

-

Thank you all for your words.

Frosty, don't worry, I accept criticism. As you say: tastes are tastes and all of we have ours.

-

Hi everyone, my name is Carlos, after several years as a silversmith, some time ago I became interested in knife making. I have done some work with recycled steel and some new steel, all done by stock removal. I'm currently preparing my forge and tools for the anvil and hope to start forging in no time, after recovering from the damage left by the covid.

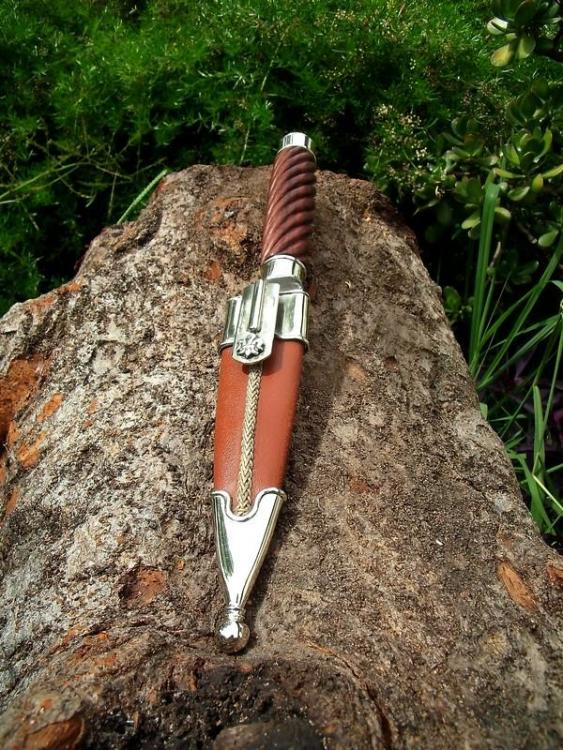

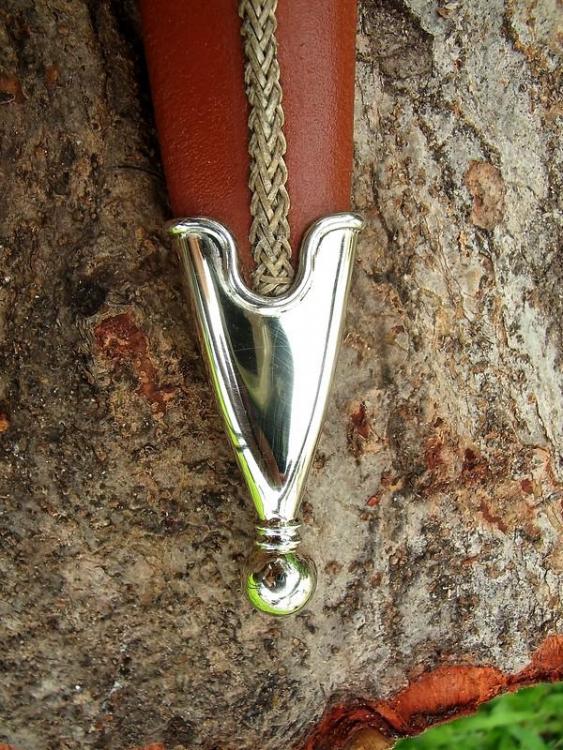

As a silversmith, I worked with commercial knife blades making them hilt and sheath, here are some pictures.

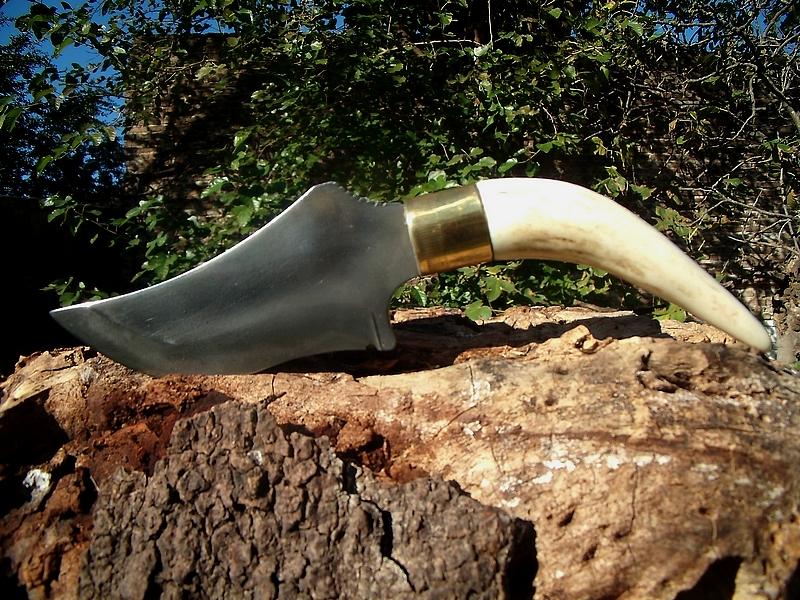

And here are some pictures of my work as knife maker

-

Thanks Thomas, it's a kitchen hatchet, we use it for butchered and chopping chicken or big meat pieces.

My late wife had no problem cleaning it, at least she never told me

When I designed it I liked the rustic finish that the steel had, so I decided to leave it that way.

I´ve learned english at technical school, long time ago, and still have some difficulties with it. I'm glad you speak spanish.

-

Hi everyone, greetings from Argentina. I'm new here, rookie knife maker.

This was my last work before the covid sent me to the hospital for 16 days and left me battered.

It's made from a disc of a disc seeder (sowing machine? I don't know wich term is correct), stock removal treeated with ferric chloride.

It's 10" total lenght, his edge is about 7 1/2" and 3 1/4" width.

The handle is made from a very hard local wood called "quebracho" (something like break-axe).

I hope you like it, and sorry if my english isn't good, I speak spanish.

What did you do in the shop today?

in Blacksmithing, General Discussion

Posted

I believed that security in the USA was better than here and that there was not so much crime there. We live worried about the same thing, that someone breaks into our workshop or house.

Daswulf, thank you.

George, yours is very good information for me, I will ask the supplier for costs and delivery times. Thank you.