-

Posts

9 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by JóneK

-

-

On 3/26/2021 at 7:36 AM, Deimos said:

For casting, maybe you can give RAM Mounts a call,

hey Deimos: i reached out to ram mounts via email days back and they still haven't got back to me. do you have a contact there that i could connect with?

-

nice - thanks deimos!

-

well interestingly enough - i was under the impression that casting would be cheaper? i would think my design would require at least a 5-axis.

-

simply put - it comes down to the design and the aesthetic.

-

ok - good to know.

firstly - it doesn't need to be shiny. with regards to choosing a metal that doesn not oxidize - what do you suggest is the most affordable? the metal doesn'r need to be ductile - and will not be used under any stress - if that helps.

and lastly - can you personally recommend a manufacture for such a service?

-

On 3/25/2021 at 5:03 AM, Deimos said:

Another thing that just popped into my head, you say you want to make it from cast iron. Have you any idea what you want to do to make it not rust?

ah interesting - i hadn't thought about rust with regards to iron. would brass or bronze be a better choice? but in doing so - would i left with a finish that typifies brass/bronze (a golden hue)? or am i completely ignorant of this process? i would prefer a more neutral tone in finish.

regarding tumbling - is this suitable for high volume? and if not - then maybe it would be best that i revise my design and apply the +/- 0.2mm tolerance?

On 3/25/2021 at 10:17 AM, ThomasPowers said:Inconel is a very high Nickel alloy good for high temps and corrosive environments---also *VERY* expensive! Only use it when nothing else will work!

good to learn about Inconel - but i think i'll try to avoid that as an option.

-

On 3/24/2021 at 10:27 AM, ThomasPowers said:

So WHAT do you want these cast in Inconel, cast iron, brass, aluminum? You would probably need to go to the far east to get a reasonable price per piece and have to hunt down a custom house that will do such small runs.

i would prefer cast iron.

22 hours ago, Deimos said:Just looking at the design I wonder how those radiuses could be done by machining. Clamping it down would be a nightmare (any action on the arms would send vibrations everywhere and maybe break something), and for each action it needs to be repositioned.

indeed - i am now considering that maybe the piece doesn't need the machining altogether.

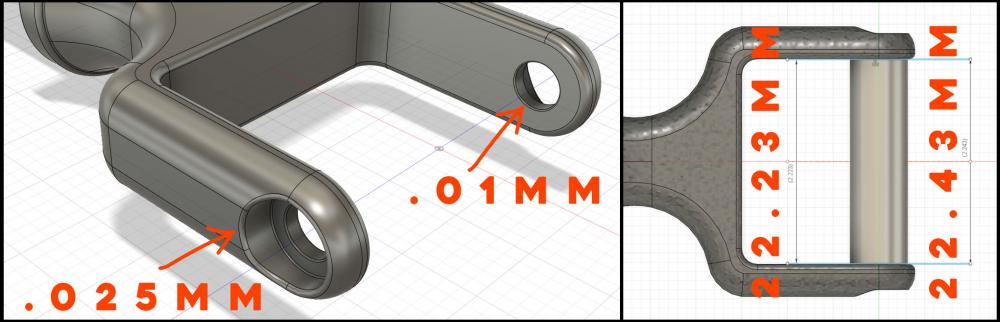

however, if i am going to provide the manufacture my design part - so that they can create the mold - i am assuming the design itself would need a minimum radius on the edges, correct? and if that's the case - would you know what those minimums would be?

22 hours ago, SLAG said:Mr. J. K.,

Have you considered a suitable casting method and subsequent electrical discharge machining. (EDM).

i haven't sorted the actual casting process as of yet - which is why i joined this forum - hoping to discover.

what exactly is (inconel)?

the piece will not be used under heavy duress, fyi. and nodebt correct - for proprietary reasons, thanks.

21 hours ago, ThomasPowers said:

21 hours ago, ThomasPowers said:Method depends a lot on the material and the price point; both of which are not provided in the original post.

the goal is high volume production - and a clean design. cast iron / stainless steel? i don't have a price point persay - it is my goal to naturally make this in good quality and find a process that is the most affordable.

i am sharing a photo of the fastener that will be used to fit the piece - quite small.

with that mention - concerning softening the edges for the cast mould - what would the minimum radius need to be?

is there a process where i can make a cast - and then have the finished cast tumbled - in softening the edges? rather than any deburring?

-

firstly - before i begin - i should make clear i have no experience in metal casting. i used to be a welder about 20 years ago - but that's about it. no foundry experience.

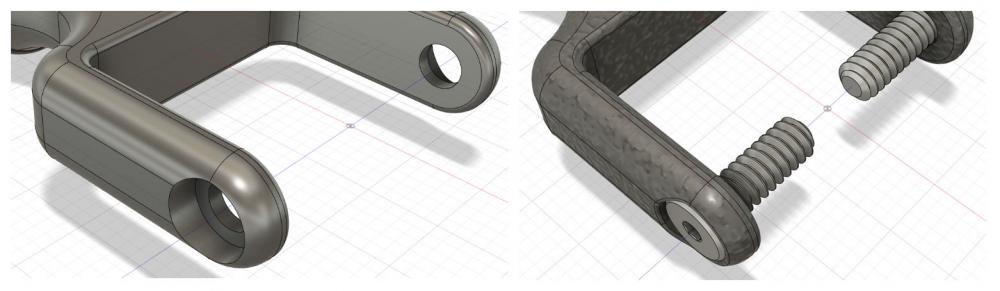

so - i have a design that needs casting. i have been told that my design cannot be sand casted and that it was recommended that i consider lost-wax casting instead.

there are a couple issues with this. i live in iceland - there are only 2 foundries - and both only offer sand-casting. so i am having to now out-source elsewhere. i am looking at either a US manufacturer or the EU.

i am needing to know & understand what casting options work best for me and my design. the design will eventually be sold in the icelandic marketplace - a country of about 360 thousand.

for the year 2021 - i am hoping for 1st round to produce somewhere between 1000 to maybe 3500, 5000. and it 2021 proves to be successful - i will amp up much higher numbers for 2022.

i was told even with lost wax casting - machining will be needed. please review the attached images regarding part of the design - small radius(s).

sooooo

- i need to source a manufacture first .

- then i need an approximate quote (including machining, if needed) for either 1000, 3500 or 5000.

can you help me?

jón

need advice (sourcing manufacturer US/EU) & casting method!

in Smelting, Melting, Foundry, and Casting

Posted

ah okay - clearly i'm oblivious to the etiquette of properly utilizing a forum - my bad.

thanks for your points however!