JADF

-

Posts

17 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by JADF

-

-

So I ran it with an .035 and .045 what are you seeing? I'm thinking the .045 needs more air but I'm no expert. Ran it for 30 minutes and the outside of the tank got to 950 F

If it can get a bare tank that hot am I safe to think it should get plenty hot once lined and a partial door on the front?

-

3 hours ago, Frosty said:

To get the scaler or impact drill to work I clamped the forms to a steel plate and vibrated the plate. LOUDNESS!

That's what I tried, obviously with no more luck than you. Once I cut an inch off most of the dowels came out pretty easy. I'm going to have to try again eventually, maybe I'll be the guinea pig for the twisted candles, does sound interesting.

-

Casting turned out kinda fugly, ended up about 3/4" thick by the time I got all the dowels out but it still seems to burn ok. If life will stay out of the way I might get the forge lined before I die. Next one I'll definitely leave the holes farther from the edges.

Band aids and burns are just life in the shop, can't wait for this BS to blow over so our club can meet again.

-

Good point. There's got to be something out there that would work, of course you'd probably have to sell a kid to afford it.

I'd be willing to bet your club meetings are more than just a little bit of a good time!

-

It didn't stick to the linoleum I had wrapped around it, wonder if graphite rods would work?

I'd like to use the pyrophile label but to many people already know I'm crazy!

-

-

Sorry Frosty! Only the first pic is relevant, the others are because I like to play with fire. Big part of the reason I'm on the volunteer fire dept.

There is only about a half inch of block left do I dare cast that thin or should I go the full inch and a half.

-

So after playing with it this is all that's left of the 2x wood block. It still burns great, how thin do you think I dare go with the casting? Was thinking of adding an outlet to hook air up to it for shutdown to keep the heat out of the plenum and eliminate the small explosion even though it is kinda cool!

-

Being able to tap into the brain trust on here is definitely raising the chance of success on the first try! I'm a firm believer in not reinventing the wheel!

-

I'm thinking of letting them sit in vaseline for awhile to see if it will soak in a little. Hoping to start this weekend if my stuff gets here.

-

Frosty maybe pull out and reapply? I guess until you try it's all what if.

-

JHCC thats a great idea and on your thread the idea of pushing them through after you pour sounds good. Just wonder how well it will work pushing the aggregate.

-

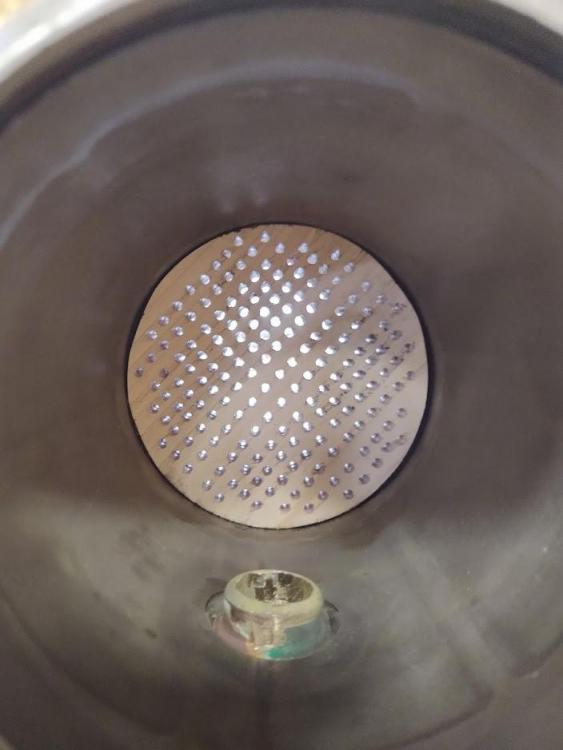

Thanks! It ended up being 181 1/8" holes. I just drilled what would fit to try it out. I'm not really looking forward to casting it but I can't stop now it's stuck in my head and needs to get out!

-

Thanks for the input Frosty, button burner it is! Just waiting on the rest to be delivered and I'll definitely be losing the tape. I do plan on using a needle valve and I'll try the bigger tip when it's all together and I get the door on. I appreciate all the advice and knowledge you guys so freely share.

I lived in Wasilla for a couple of years back in the 80's, great place!

-

Got the tee burner put together with an .023 tip. Used a 1 1/4" 3/4" tee just cause it's what I had laying around. Seems to run ok. It's got 25 psi going to it and just turning down with the valve for now.

-

.thumb.jpg.a02f7d1e327f61cdb50faa1411311a36.jpg)

.thumb.jpg.3843da0e809b31c671a4f06e6b5e79c1.jpg)

.thumb.jpg.65e8198cacd26fc910c6be4933f8803f.jpg)

.thumb.jpg.52889e31da176f0182326ca0d07f962a.jpg)

.thumb.jpg.470ee650604bf91d162d73c345d66e2c.jpg)

.thumb.jpg.65016c6c723e139fcb5454ca0d672634.jpg)

.thumb.jpg.dce5fa374a13f9eba07dfe440907838c.jpg)

Naturally Aspirated Ribbon Burner. Photo heavy.

in Ribbon Burners

Posted

Fired it up for 45 minutes. Got to forging temp no problem but need to get the door on to make welding temps.

Thanks for all the input on this, overall I'm happy with how it turned out and man is it quiet! There's room to tweak and improve but I don't have to start from scratch!

Thinking I should recast the burner so it isn't recessed so far and maybe drop a few holes to leave some more room around the edges. It backfired a couple of times and the bottom of the plenum got to the 300 deg range and the top of it was125 deg