bbaley

-

Posts

5 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by bbaley

-

-

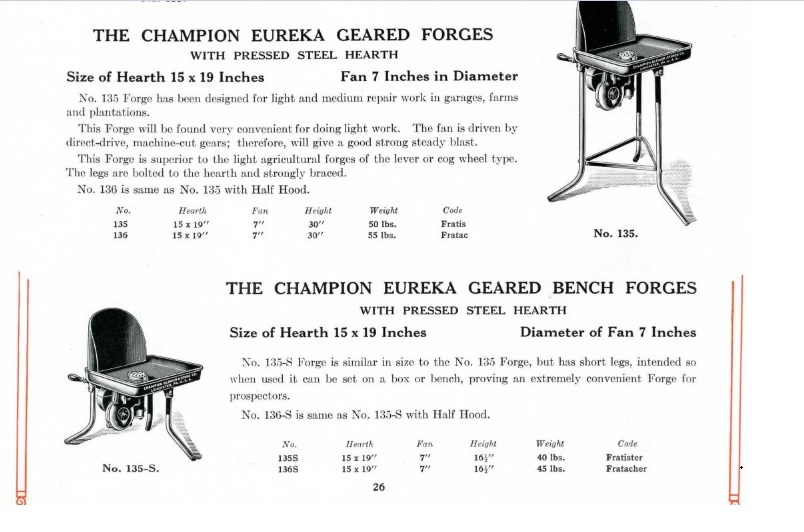

thanks all for the help! I think I might try to recreate a 135-ish type with legs/stand. albeit sans the cast iron (although based on the small size I could probably find a really big cast iron skillet?). or just weld up a super thick facsimile... I kinda of like the style of the 135 with legs in the catalog, and it matches what I would use it for, light use, occasionally...

-

The pictures did not work from my phone... so here they are.

It looks like someone drilled holes in the side ?

I did look at the old catalog... the pictures don't make it easy to identify.

The lack of model # and the holes in the side made me wonder... based on where the holes are I can't imagine they are anything other than some farmer performing a little "ingenuity" on them ?It is in seemingly great operating condition, although the (what I assume to be) bronze bushing has a tiny bit of slop to it, but very little backlash at all overall. The gears are in great condition though...

Anyway, I plan to use it, just curious what it was originally.

My guess is it was on a a 135 or 136 Geared Bench forge because of the integrated Tuyere/ash dump ?

I am not knowledgeable in coal forges, my apologies. -

Hello!

Is there a definative source for identifying Champion Blower and Forge equipment?

I looked on antique equipment site and a few others but havent found this exact blower yet I just acquired.

I was hoping there was an equivalent site like the Disstonian institute for handsaw nerds, but no luck.

it has no model markings (400, etc) just the brand....

-

Hi all,

I am not sure if this is the best forum for the question but...I have an inexpensive Infrared thermometer supposedly capable of measuring up to 2400F, and has adjustable emissivity setting.

I have been trying to find some general information regarding emissivity of forged (or heated soon to be forged anyway) steels that are in the range of 1400-1600 F - or generally critical temperature ranges for quenching , or even just getting better idea of what "colors" are what temperatures in my environment (lighting etc) to my eyes, etc.

I have started looking through various documentation, and some papers, but having a hard time finding some general ranges to try or expect.

The materials would be for me, pretty typical simple steels like 1084, O1, 1095, etc...I don't really have a way to "calibrate" - my only thought was I might get close (sorta?) with a known material if I could time when it loses magnetic properties/critical temp? then try various emissivity settings until they seem like a close match to expected temp ??? totally guessing, I am a novice when it comes to this stuff.

Any help would be greatly appreciated!

identify Champion blower and forge blower

in Bellows, Blowers

Posted

Ok yes - I think I saw a plan for brake rotor forge on AngelFire or somewhere... I will check into that