Ross_FL

-

Posts

77 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Ross_FL

-

-

I could be overgeneralizing here, but I think most knifemakers who have moved beyond the "any scrap that'll harden" phase end up ordering steel. That's how I get most of mine. Places that carry reasonable selections of medium/high-carbon or tool steel steel on the shelves just don't seem to be that common.

Alro does have a lot, but it ain't nearly everything I can imagine. I don't see S5, 5160, 1084, W1 or W2, for starters.

I don't see S5, 5160, 1084, W1 or W2, for starters.  It's cool that they have 1060, though.

It's cool that they have 1060, though.

They actually do have S5, W1 and W2, at least their catalog says they do.

I talked to them earlier today, they wanted over $100 for a 24" flat of O1, and the W2 wasn't that far behind. Not to mention they acted like it was a hassle to sell anything less then $50000 worth of metal.

It's okay though, just fund a set of leaf springs from a Chevy for $20. :) -

Yeah..they are cruddy to work with...there are numerous accounts from the Indian sub-contenent that mention the amount of additional work required and the fact that a much higher quality steel was required to be amalgamated with it to get the Fe/Ni material to be workable.. My own experiments and research confirms that.

I have probably made more knives outta this stuff than anyone else in the US...It is a PAIN to the Nth degree to work sometimes but it is unique..Just that there are much higher quality materials available at much lower prices to use that will result in a much "higher quality" knife than extra-terrestial iron...

JPH

Yeah, I'm talking strictly for a conversation piece. TO be honest, I think it would cooler to have a full meteor or cross section n the end table, but if I came across one of these at a show somewhere.... I don't think I would be able to resist. -

If ur looking for 5160 why not ur local scrap yard (leaf springs/coil springs)....

Gene

I wasn't going to fool around the scrap yard if I can just go get 1060 at the Alro, it's less then $10 for enough to make 2 knives.

I just don't know why they don't have 1095, they literally have everything else you could imagine. -

Tomorrow I'm heading to a local metals supply store that also has a retail odds and ends outlet. People I've talked to said it's really nice.

Im looking at their catalog though and I don't see what I want, I was hoping to find a 5160 or 1095.

Alro Steel

Any suggestions? Maybe the 1045. -

Those knives are for sure well done with alot of attention to detail and construction..maybe even great knives,But I am not sure I will ever see the coolest knives ever,,,,

yeah, you got a point.

maybe the golden butter knife from that movie with Eddie Murphy, but that's it. -

I'm sure most of you are familiar with these, but if you're not, check them out.

Cosmic material forged. -

Especially in this case you get what you pay for.The fitting that allows the belt to be swiveled on these is made of low grade cast iron and breaks easily.I have been asked to repair 3 of them and told the people who brought them in it was a waste of time as the rest of the machine was of equally low quality.

My suggestion would be to look on Craig`s list for an older,better made machine.One that is built to stand up to metalwork rather than a woodworking machine.They can be bought relatively cheaply nowadays.

Thanks Bob, HF scratched off the list.

I bought a heat gun there that worked for 15 minutes and its that same orange color as the grinder so I was wondering if it was the same cheap crap.

Then again, the heat gun was $3, so that's about one use worth!! -

HF has a belt grinder for $75, it looks like this HF grinder

I'm guessing it's garbage, but does anyone happen to have experience with this model? -

ALS army navy is a great place to have FFL transfers.

-

Yeah, I saw that, guess I can also scratch gloves and tongs off the list. And if you can make a good living in Africa making blades and other primitive weapons........ Hmmmmmm

-

lol

You're telling me I don't need a forge or a hammer? -

Coming from a construction engineering background, I would just pour a 12" - 18" thick monolithic 5k @ 28 days mix with a super plasticizer additive.

I don't know how big you want your building though.

I don't know what a power hammer calls for but I do know what I've seen done on the above slab 24 hours after it was poured. You should be fine.

You could always bump up to a 7k, but just make sure you tell them super-p. This is the mix we've used to support $50 million dollar GE gas turbine generators. -

The production quality of that video is really impressive, thanks for sharing.

-

I second the thought about the mill. You should be able to get a drill chuck for it pretty cheap. Look at Enco. The mill should tell you the taper of the quill. Its probably MT3 or 4. From there you can get an adapter for a drill chuck. For example, I think I spent $30 to get a drill press up and running. I bought a 4MT to 3JT adapter, and put my 3JT chuck on the press.

How heavy is the steel you're using for your anvil? Any sense of what kind of steel it is? Until you find another, bigger anvil, probably your best bet is to find a way to mount it, so that it's as solid as possible.

Last, get a smaller hammer. You can probably find a 2 to 2-1/2 pound cross pein or ball pein at a garage sale for a few bucks. If not, you can buy them (as mentioned) at a local hardware store for $10-$15. A lighter hammer will be more effective than a heavier one.

As far as the anvil, it's about 45-50 lbs. It's the base spacer plate for a concrete compressive strength machine a friend of mine borrowed from their CMT lab. I've hit it as hard as I can with that hammer you see in the picture and it doesn't dent any. It's a $300 hunk of metal so I'm guessing it's pretty solid. I actually have a piece that screws into the bottom of it that I can use to tension it down to whatever I set it on. -

Forge looks good. Fire it up!

A milling machine is very useful. I would be reluctant to give it up. Cant you get a drill chuck for it and use it for drilling? You could probably get the tooling for cheap on ebay. Well only you know your priorities. If you need to get it on a truck, call a tow truck. If you set up the rigging yourself it shouldnt cost $50 to have a tow truck lift it onto the bed of a PU truck

http://www.jettools.com/us/manufacturing/en/product.html?node=4634&product=947

r-8 3" quill. -

Forge looks good. Fire it up!

A milling machine is very useful. I would be reluctant to give it up. Cant you get a drill chuck for it and use it for drilling? You could probably get the tooling for cheap on ebay. Well only you know your priorities. If you need to get it on a truck, call a tow truck. If you set up the rigging yourself it shouldnt cost $50 to have a tow truck lift it onto the bed of a PU truck

Ive moved it multiple times, it's just a pain and costs to rent the cheery picker.

To get that thing up and running I would need the collets and a vice to hold work and that's not even including the bits plus I need the lube set up plus I need to get a 220v setup. I don't know though, I'll probably just keep it sitting until I want to get back into it. It would be cool to use!

As far as the forge goes, you've beat some sense into me. I'm going to pick up some hard/soft brick tomorrow Thursday and revamp it and get it fired up this weekend.

I've made a whole list of the little things I need get and need to do to have a successful bladesmithing weekend. I am also going to just get everything situated and in place well ahead of time.

I'll have a photo documentary of the whole things of course! -

I would also look into the ITC. I did quite a bit of research when I build my forge and found that the ITC is supposed to reflect nearly all of the IR back into the forge for max heat and also increased efficiency.

-

I'll see what I can do. If I did rebuild, I would take the same approach, just use an 8" or 10" pipe instead of this 12" steel bucket and make the chamber 4" inside instead of 6".

I do like how the kaowool got stiff after the first use. It really locked the cast chamber in there really solid, it doesn't budge. I actually broke an identical chamber I made because they are so fragile so I'm actually glad that the wool has locked it in place.

Is ITC that's 2 years old still any good?

How does my original coat look?

Here are some better pictures. -

Luckily for me, I found a pottery store that has everything I could imagine. ITC, wool, hard and soft bricks, cast mix.....

Oddly enough, when I went in I found my friends dad was the store manager! -

maddog

Thanks for the advice. I may consider retaining the forge body if people think it has hope. I was using soft brick for the front and back and wasn't getting past orange/yellow. Maybe I didn't give it enough time, who knows. I ITC'ed the inside if you can't tell. I get a pretty good flame with the T-Rex.

So what did you think about my dual burner idea? I would probably need a new forge body if I decided to go with dual burners.

Here is the guys shop that I kind of want mine to resemble, I like his portable forge and anvil cart. I've talked to him a few times, he makes some really nice stuff with what you see on his shop pages.

Jesus Hernandez Shop

Another question, what should I staring keeping an eye out for as far as practice metal goes?

Forgot to mention, I have this Jet mill that I've got about half way refurbished. Mechanically it works great, cosmetically it's not so great as you can tell. It would work great as a drill press, but the collets and tooling would cost as much as a nice anvil. I'm thinking about selling it as is and that should cover alot of the stuff I need. Problem is, it's in my parents garage, I need a truck and a cheery picker to move it.

I also found a really nice 5" vice with anvil on clearance at a wood supply company near me, and I have the angle grinder from my home improvement projects!!

-

Hey guys, about 3 years ago I tried to get a forge up and running that I could shape blades and weld with. Money was much tighter then but now fortunately it will be much more affordable for me. I work with software, so I've always felt a need to get out and do things with my hands. The one thing that I've never lost interest in is forging, so I think I need to give it another try.

Here's the wreckage from my first attempt.

Here is what I' wondering....

-The forge body is a steel bucket filled with wool and a 1" thick cast refractory shell that's about 6" inside diameter. I think I need to ditch he entire body and start over. I want my forge to be hot as hell inside, and designed for a blade. Any thoughts on this?

-That's a 3/4" T-Rex burner I have. I know that it's not enough alone, but even the $40 difference was a big deal when I bought it. Should I add a twin 3/4" or opt for the 1"? Will going with the 1" make he gas line/pressure setup more complex? Will either of these dual T-Rex setups get me the heat I want?

-Other then what's in the pics, I don't have any of the proper equipment. Any advice on finding an anvil, tongs or hammer? Also, what would you consider the most important grinding tool I need to start looking for?

I'll take any and all advice. -

Cool. Most I see have lab test docs with them when you buy.

You've got me thinking about buying one. I'm not ready to forge one yet, but if I am going to try eventually, I might as well get one now and let it sit on my coffee table until I'm ready. -

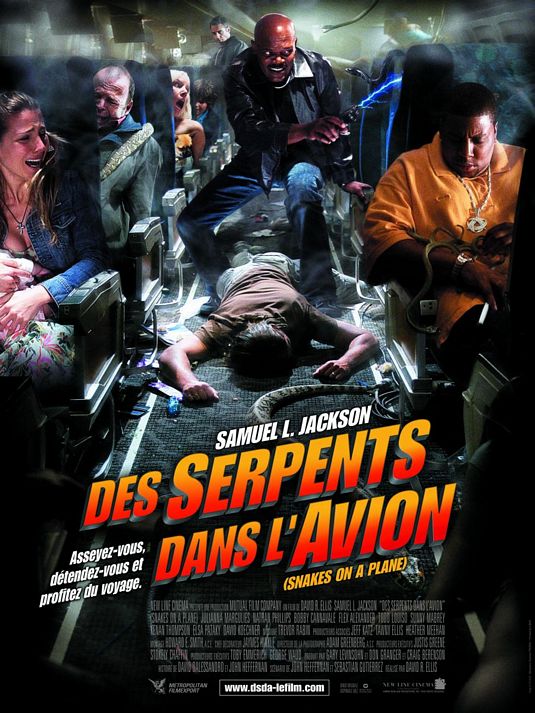

No, more like this guy for director!!

-

Steve, what would one with a blade in mind look for in a meteorite? Nickle and silicon?

Harbor Freight belt grinder

in Grinders, Sanders, etc

Posted

$800 and I gotta build I myself??

Uhhh, thanks, I guess.