Pyromansfire

-

Posts

17 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Pyromansfire

-

-

-

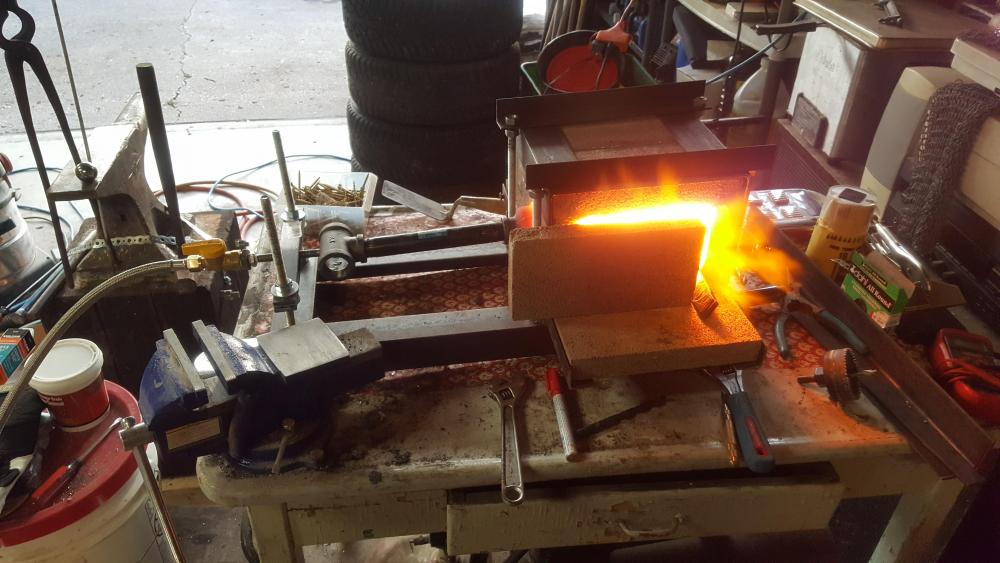

Thanks, for heat treatment i normalized it by heating it to what i call cherry red and allowing it to cool to room temperature. Then i heated it in the forge till it was non magnetic and went till it was a bit brighter in color and quenched it in oil. I then cleaned it up with the belt sander being sure to keep it cool. I then used a torch and heated the spine of the knife till i got a nice straw color to the edge of the knife and quenched in water did some hand sanding, a paracord handle and sharpened it sharp enough to shave with

-

-

-

Yeah for simplicity sake at this time just to get a forge going i plan on making a simple t burner to go in a fire brick box forge. This should at least get me and my son working in the shop. Your input on the burner 101 thread shows you are very knowledgeable on the subject. Thank you for your input I appreciate it.

Pyro

-

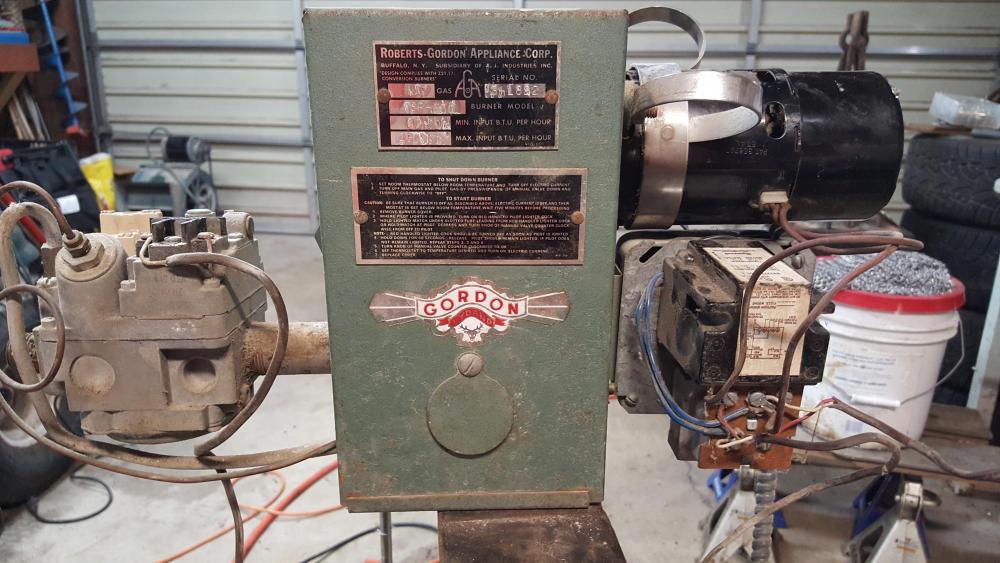

It is a natural gas burner and depending on the gas pressure input to the burner it will put out anywhere from 60k to 250k btu/hr and if i convert it over to propane (just a simple change of springs in the gas valve) it should nearly double that output if i leave the natural gas orifice in. As far as the flame pattern it comes out in two swoosh shaped jets or i could remove the baffle at the end of the air tube to create a single jet style flame. But, if as Frosty says someone in Alaska created a commercial sized forge out of a fuel oil burner, it would be to large of a burner for me at this time. Thanks for the input guys i appreciate it.

Pyro

-

-

Well the second anvil is mounted. Dont have a forge as of yet but i made do with a map gas torch and hammered out a marshmallow roaster that quickly went into the scrap bin. But it sure does feel good to move some metal. Can not wait till i can make a parts run to menards to get the rest of the supplies needed to put this forge together. Then i can smith in earnest. I know the kiddo sure is excited.

-

The legs on the stand are there to to add some more stability till i find a good lay out for my shop then it will be anchored to the concrete with angle iron and red heads. As far as the treated timbers go we should be fine as long as we do not light it on fire and breath the smoke.

-

Well, i got one anvil mounted and the pieces for the second cut. Killed the blade on my skill saw trying to cut those 4"×16" rail road timbers to size. I ended up using my chain saw for the second one. I just used plumbers strapping to hold the anvil in place while the construction adhesive cures. Used the jack stands and bucket to find the right anvil height. Going to put the other stand together this week after work and finalize the plans for my propane forge.

God bless and have a great week.

-

13595 is the serial number on the Arm and Hammer if some one has a copy of AIA and could get say the date of manufacture or any other info that would be great

-

I am hoping to get the anvils mounted up this weekend. Been browsing the different stands on here getting ideas for the materials i have on hand. TPAAAT yes it does work. You never know who has something just rusting away nearly forgotten in the garden shed. I am hoping this will build lasting memories and good bonding time with the kiddo.Safety first of course. Thanks for the feed back guys i appreciate it

-

Well here are a few videos of the ball bearing tests and tapping on the anvil with a small hammer. I just talk about blacksmithing alot with just about everyone i meet and things just seem to find me.

-

I will have to try to see if the face is separating from the body on the arm and hammer. If it is failing is it worth welding it back on. ( i picked it up for my eight year old son to work on) i paid $75 for it and $25 for the Columbian so i would not really be out anything the kid would still be able to beat on it.

-

-

Hello, new to the group trying to get into blacksmithing, i am a welder by trade. I have picked up two anvils one is a 63lb arm and hammer the other is i think a Columbus 97lb. I would like to know more about them. Say when they were made,if they are any good, any and all information you can give me would be appreciated.

New to the group looking for info on my anvils

in Anvils, Swage Blocks, and Mandrels

Posted

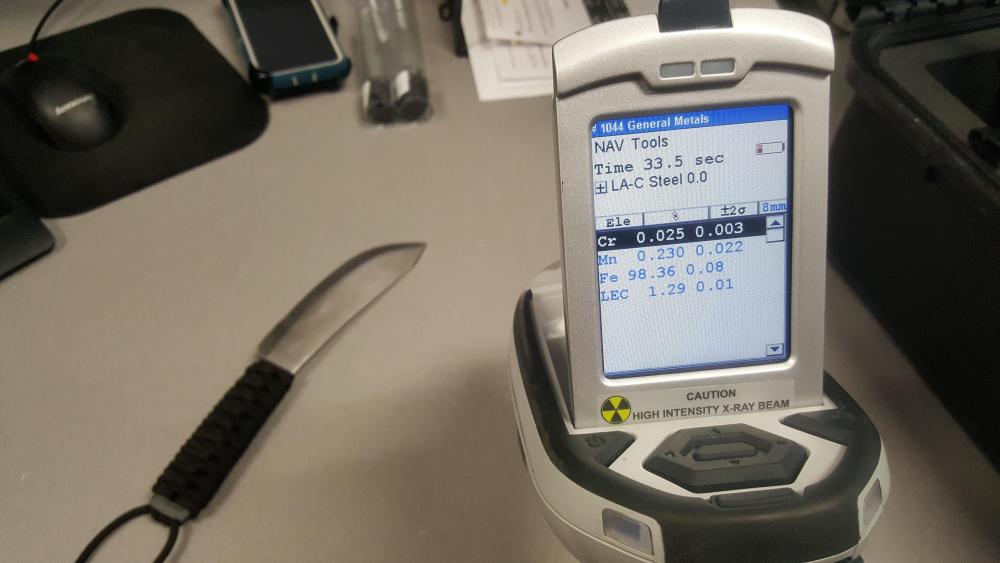

That XRF gun is no toy, you can easily sterilize yourself or others (no more kids). As the lab tech told me that thing was 50k they keep it in a safe. We mainly use it to identify the different kinds of metal in the yard.

Pyro