Dano46

-

Posts

11 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Dano46

-

-

On 1/11/2022 at 5:01 PM, ThomasPowers said:

Flats on the feet would fill out the stampings.

It has the letter W on both sides. Any way to date it?

20 hours ago, Rojo Pedro said:Nice score Dano !!!

Right time and place I would guess. It looks lonely for some hot steel. .have fun

Thanks!! I definitely will

-

-

-

Frosty the Lucky, BartW, Thomas Powers - great advice! Thanks

-

jlpservicesinc thanks! I’m going to have to do some research

Daswulf agreed I can’t look at these welds. Going to have to make a new stand.

-

Well. I traded a guy at a job site I’m on an acetylene tank key (no lie) for this anvil today! He said It had been sitting there not being used for years

Anybody have any idea what kind it is? Or year? Not sure when I’ll have time to take a wire wheel to it. Part of me wants to leave it on the stand the way I found it to preserve it but the other part can’t stand looking at the nasty welds.

Either way any help or recommendations are greatly appreciated

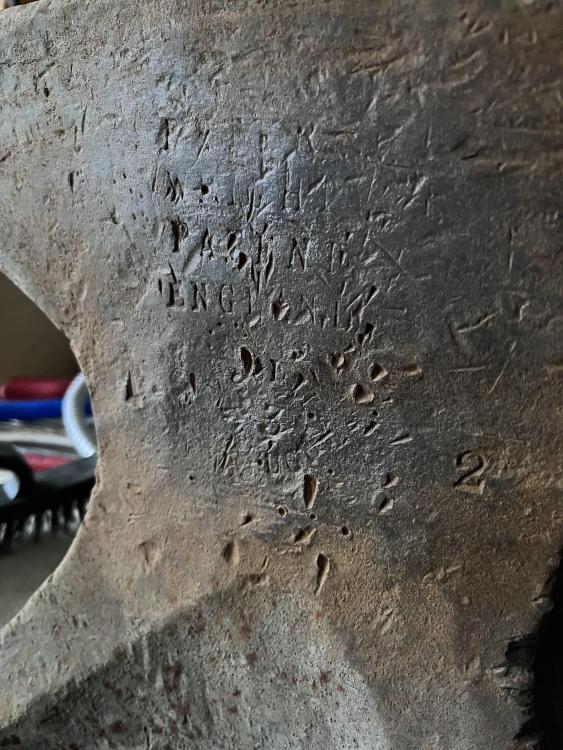

Is it an Armitage?? 2 Armitage anvils in under a month..... crazy

-

33 minutes ago, ThomasPowers said:

Not to diss you; but I have seen a number of anvils badly damaged by professional welders. They may have been great at welding what they were used to; but dealing with the hardened high carbon plate on a low carbon wrought iron body was out of their experience---which is why I said to have the welder read and follow the Gunther/Schuler process.

Not many welders work with high carbon steels that need to retain their current heat treat and even fewer welding real wrought iron. Many have never worked with real wrought iron, the material, at all.

Anyway forewarned is forearmed and I'm sure you will take appropriate precautions. BUT be aware if you do a good job of repairing it and it gets known there may be a bunch of folks with battered anvils beating a path to your door!

Point taken. I will research the proven Gunther/ Schuler procedure that you recommend. Thanks for your expert advice! It’s much appreciated.

-

51 minutes ago, ThomasPowers said:

Not even Crown Prince....takes your nasty TINGY anvils, I loves my thuddy Fisher my precious....also my A&H, my PWs, my HBs, my Powell...

Actually you can do a lot of damage welding on that anvil if you don't what you are doing! Do you know the right temp to preheat to avoid auto quenching to brittle? A lot of folks will weld up damaged edges only to find that larger chunks break off due to HAZ cracking.

Now if you have some welding skills research the Gunther/Schuler method of anvil repair Robb was the smith for Sandia National Labs and their method has been proven in on hundreds of anvils over decades of use. They will cover the proper preheat and rod to use. If you plan to have someone else do the welding MAKE SURE THEY FOLLOW the G/S process! Accept no others.

Thanks! I’m actually a welder by trade. I will look into this. I must admit though it’s really just superficial. Even if I was to weld her up I would still do majority of work on the original face. It would break my heart to damage something from the year 1830 that still exists!

56 minutes ago, Daswulf said:Oh, and don't weld on it. Use as is for at least a year to see if it doesn't do something you need. Then decide if you need more. It's good as is.

Good point!

-

4 minutes ago, JHCC said:

Trash? TRASH?!? You do realize that you’re talking about The Undisputed King of Anvils, don’t you?

As noted, though, it’s been through a lot. The good news is that it still has its face, and so long as it isn’t delaminated, you should be fine. Tap it lightly over the face to see if you hear any changes in pitch: a solidly welded face will have a nice clear “ping”, while a delamination will have more of a “whack” or even a “thud”. Anywhere that pings should be safe for use.

Awesome! Thanks for the info. It pings beautifully on the remaining face plate

14 minutes ago, Irondragon Forge & Clay said:What Das said, a perfectly usable anvil. BTW Welcome to IFI... I always suggest this thread to get the best out of the forum. READ THIS FIRST

Thank you sir. I will head over and do some reading. First forum I have ever been on. Lol

24 minutes ago, Daswulf said:Well, what's up with it is the face plate on the tail is delaminating and much broken off. The good news is it looks like it's still a perfectly usable anvil. At least mostly half of it which is fine. Looks like the pritchel hole is still usable, and you can still use hardy tools in the hardy hole but I wouldn't do heavy hitting back there.

0.3.12 in hundredweight would have been 96#. They were usually give or take 10# and probably a little less with the missing pieces.

No worries tho, you have a usable anvil there. Just avoid hitting on the edges where the faceplate is broken.

Thank you for the info. Much appreciated!

-

Hi everyone. New guy here. What’s up with this Anvil? I’m using it as is now and don’t think I’ll mess it up by welding it. It’s an m & h armitage 0.3.12 mousehole anvil. I bought it on the cheap off a retired farmer. I’ve just buffed it with a buffing wheel a bit to identify. Any comments are appreciated unless your going to say it’s trash. Lol

Dan

I guess I posted this in the wrong spot. Sorry

Show me your anvil

in Anvils, Swage Blocks, and Mandrels

Posted

Thanks!

Don’t “need” to know. Just curious. Thanks for the info friend!