ColinHeath

-

Posts

13 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by ColinHeath

-

-

Thanks Mikey,

the bire through brick is same bore as outside of flame tube it’s just the picture makes it look off (the black bits is bottom of forge).

Thanks Thomas, i don’t think any burning in the tube as it stays cool for a while before heating up although I had turned down gas pressure so maybe it was burning back into tube?

what sort of burner do you use?

maybe go for side mount like in a foundry?

I am planning to make another forge so no problem to change

-

Today is the first day I made something useful in the forge..

I saw these simple tongs on the black bear forge YouTube channel that he had seen somebody using.

Very simple with a slip ring to adjust. Had some fun trying to the ring round and now have one too small and one too large (although large one is good for large objects)

will make another ring tomorrow when I am sure my forge burner is safe (another thread)

Just wanted to share as it was great fun heating and beating and the new anvil and stand worked well.

-

Hello All,

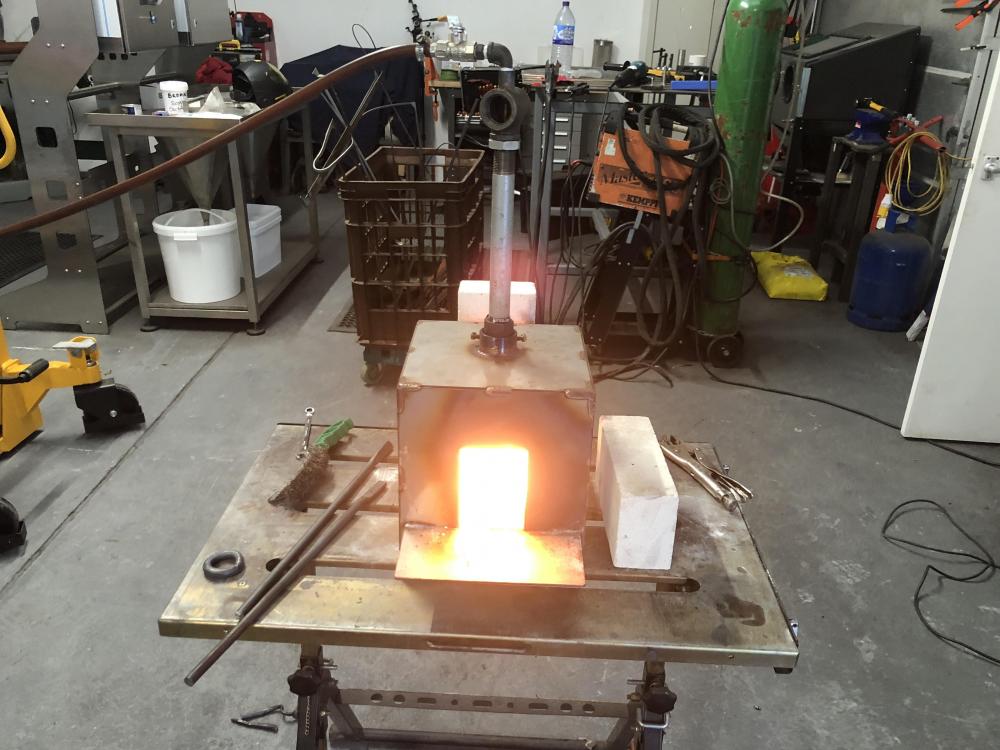

I have attached pictures of my setup to help with discussion. I was running my forge today and being very cautious around the burner not getting too hot as I have rubber hose quite close.

my questions are:

1) Will the burner always get hot right the way through when running for some time and if so, should I be concerned about the burner (I appreciate the rubber hose is an issue)

2) Should I install a long length of copper tube or black iron to keep valve and rubber hose cool and not worry about the burner tube itself?

Any help would be much appreciated.

thanks,

Colin

-

Haha thanks Gents, black it is then!

-

I finished my anvil stand today for my newly acquired anvil.

8mm mild steel plate TIG welded with 3 passes.

It rang a bit when on the stand so bedded the anvil on silicone and it has dulled it down nicely.

the openings at bottom are to allow pallet truck underneath to move around.

Here are a few pictures of the build and the finished article before paint.

Should I paint the stand and anvil blue or black? Blue feels like some kind of sin!

-

Haha thanks Thomas,

Im on it

-

-

On 12/1/2018 at 7:55 PM, Irondragon Forge & Clay said:

Nice find, if I recall French anvils have a hardy hole that exits on the side like the front one on your anvil. Have you read about not grinding, milling or welding on the hardened face plate?

20 hours ago, Glenn said:A big open warehouse door does not mean you can not accumulate CO somewhere. Several feet outside the door would be better. A CO detector inside the building will alert you to CO.

The second hole is there so you can figure out ways to make use of it.

Begin by firing up the forge and just beating on some metal. 2 pound hammer is plenty and hold it like you would a tennis racket, thumb wrapped around toward the fingers. Anvil height has been discussed in other threads. Make the anvil height fit YOU. If the metal (mild steel) is high orange to yellow, hit it. If it cools to medium red, warm it back up. You can feel when the metal moves, starts to get stiff, and needs more heat. Listen to the hammer hitting the metal with a good solid blow.

Modeling clay is your friend. Use the same hammer and watch the clay move when it is hit. Now hit it again with the intention to move it in a specific direction. Get a short piece of say 1-1/4 or 1-1/2 pipe and use it as a fuller. Watch the clay move. Classes are good but you should already know which end of the hammer to hold before you get to class. LOL

Haha I think I’m ok with the hammer holding, it’s my favourite tool, I even have a left handed one

that said I totally understand that stretching and shrinking sheet metal is very different to forging.

18 hours ago, Irondragon Forge & Clay said:Also which end of the steel to hold.

I would like to say that’s stupid but have picked up way to many freshly welded parts to claim it

7 hours ago, JHCC said:Welcome to IFI! If you haven’t yet, please READ THIS FIRST!!!

Thanks for the welcome, yes I’ve read it

-

Thanks for the detail. Yes i don’t want to ruin hardness of top plate or indeed the temper so will stay clear of trying to pretty up the top

-

Thanks for the welcome and advice Neil.

Yes I use forge with big workshop door open and always wear glasses.

I will be looking for a course before I drive in too many bad habits

-

-

Hello All,

I run a fabrication and engineering company that does mainly stainless steel for food and drink but have a big interest in learning to forge.

I am In the U.K. and keen to learn but also know this will need lots of practice.

I have a super cheap 20kg anvil and today picked up a big beast which is probably around 40-50kg which I would like to identify.

Looking forward to learning and sharing as I go.

heres a picture of the anvil I picked up today and it has an extra hole close to the step which I have no idea on it’s purpose.

the anvil has handling holes but no markings I can find as yet, I will start a thread.

I have also put a picture of my first attempt at a leaf, lots more to learn and patience thinning down the stem etc.

T Burner getting very hot

in Gas Forges

Posted

No, I made this following other plans before finding this place. The burner runs lovely and assuming heat going back up is due to it being top mounted.

Yes it is galv but it doesn’t get hot enough for that to be a worry (I know risks as I weld and fabricate and have had galv flu before so take it serious)

Thanks Thomas

my next build is a 15kg propane tank and have Kaowool to insulate and will them rigidise and coat to prevent fibres getting out.

im thinking maybe a side mount for burner but wondered if there is a valid reason for top mount as so many do it?