Fuji’s forge

-

Posts

68 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Fuji’s forge

-

-

No, on the other side of the stand. I have another steel plate with 2 holes to hold the handles in a vertical position when in use. I have 2 holes in the side of the stand to place the handles into when moving this unit. If u look closely u can see the holes in the I beam. I have another image somewhere..

-

-

I will leave it be then…

-

-

Looking for ideas, thanks

-

-

-

Gotcha

-

-

My 5lb hammer bounces about 6 times from about a 3” drop. Not very scientific but seems good to me over most of the surface... I was thinking about putting 1/8” rubber black gasket material under the block to help with the ringing. Would that affect the rebound from the block not being in direct contact with the plate? I don’t know what type of steel the block is. But the sides of the block has what appears to be die lines. If you zoom in on the block you can see them clearly. Not sure if that is a hint or not?

-

Wow, is that solid or welded pieces?

-

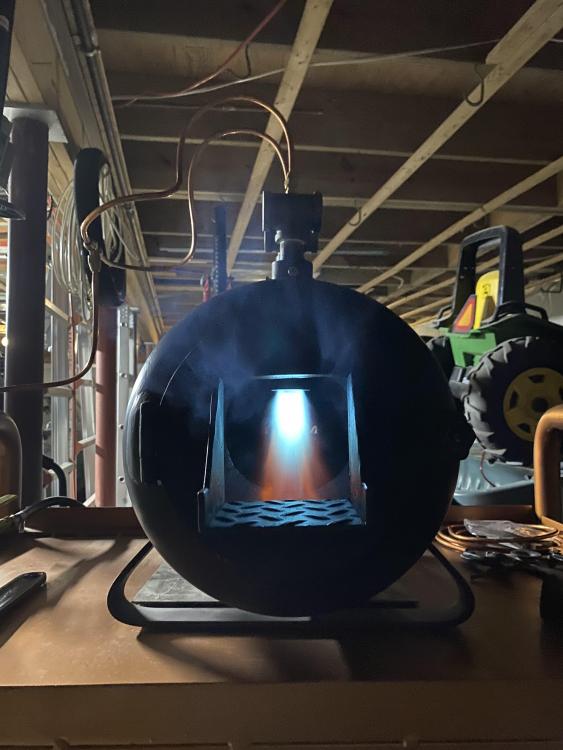

Propane, I will post photos...

-

Hello to all, please say hello to Bessy. I created this Anvil from a 8”x9”x5” block of steel for top block. Corralled by a 1”x1”x1/4” angle. Supported by a 13.5”x13.5”x1” plate, on top of a I-beam measuring about 12”x12”x2’x107lbs/ft. It weighs about 360lbs. I drilled 13/16” holes for 3/4” x 18” rebar removable handles for easy moving. I still have 1” gussets to be welded under the top plate to the I-beam, as well as heavy gauge wire mesh for shelving inside the beam web to hold hammers, tools, ect...

Hello to all, please say hello to Bessy. I created this Anvil from a 8”x9”x5” block of steel for top block. Corralled by a 1”x1”x1/4” angle. Supported by a 13.5”x13.5”x1” plate, on top of a I-beam measuring about 12”x12”x2’x107lbs/ft. It weighs about 360lbs. I drilled 13/16” holes for 3/4” x 18” rebar removable handles for easy moving. I still have 1” gussets to be welded under the top plate to the I-beam, as well as heavy gauge wire mesh for shelving inside the beam web to hold hammers, tools, ect...

It has a nice rebound and ping at this point even without the gussets in place. My next major decision is to decide if I should weld a 3/8”x3.5”x9” piece of AR500 plate in the center of the steel block? I know the steel block will deform over time. So should I or shouldn’t I face the top block with hardened plate? Any and all comments are welcome...

-

Hello to all, I am new to forging and in the process of creating couple homemade forges, anvil, shelving ect ect... Where can I show my work, I have a few questions about my anvil design...

Thanks

A collection of improvised anvils

in Anvils, Swage Blocks, and Mandrels

Posted

Thanks for the design upgrades, I’ll use it and c where best to place some handles.

Frosty on a side note:

I used your frosty design torches, which I am very pleased with. I also made a homemade 2 torch gas forge. I’ll post video of it working in time…

Thanks again for your comments and design upgrades…