-

Posts

10 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Turbo Dog

-

-

Don't sweat it out, I'm not jumping into building a forge without due diligence in researching it. I have used a forge in a college metal working class where we melted the metals to do a sand casting of bronze. Just haven't built one from scratch.

Pretty much wore out my available railroad spikes with last nights grading so hopefully this weekend I will be doing the welding to mount the bucket teeth.

-

Thanks, it does look easy to build without breaking the budget.

-

Okay...it took some searching for me to figure out that JABOD is Just A Bunch Of Dirt, and it lead to a thread of someone building one. Now I could use some help with the terms 'clinker' and 'tuyere'.

-

Ok, I don't have a forge just an Oxy/Act torch...but in case I get the urge to heat them up and pound on them with a hammer I'll keep them around.

-

16 hours ago, ThomasPowers said:

How do you harden mild steel? You throw it away and replace it with an alloy that will harden.

Thanks, that looks like great advice. I'll try mounting the bucket teeth next and see how they hold up.

-

Guess I started this in the wrong section and they advised asking my question here. I have some old early 1900's railroad spikes on a home made harrow that is being dragged on a very hard compacted road made of recycled asphalt. They have suggested old coil springs would be better to use or to Super Quench what I have. I also have some new bucket teeth and am wondering if they will do better. I end up grinding off about a 1/2" off the spikes each grading session which drags the harrow about 2 miles.

https://www.iforgeiron.com/topic/60000-how-do-i-harden-railroad-spikes/

-

Thanks for all the info...the railroad spikes are very old from an abandoned railway, probably the early 1900's. I'll check with some of the auto repair shops to see if they have any coil springs laying around. Or I'll try that Super Quench method. The spikes are able to rattle around in their mounts and the harrow has done a much better job on the very hard well compacted recycled asphalt road since I added two pistons out of a Cat 3608 for weight, but it is also eating the spikes up faster.

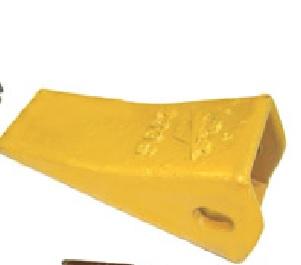

I found and bought some new bucket teeth, that are similar to this picture. Would they be already hardened?

On 10/2/2018 at 7:12 PM, WayneCoeArtistBlacksmith said:RR spikes are 5/8" square. they are about .29 points of carbon is high low carbon steel. If you forge the blade, then quench it in Super Quench (5# rock salt, 24 oz blue Dawn dish soap (the concentrate) and a bottle of Jet Dry (dish washer spot remover) and fill to 5 gallons of water) you can get a hardness of about 53 RC. Try bringing the spike to non-magnetic and quenching in water, then bring it up to non-magnetic and quenching in Super Quench and listen to the steel SCREEM!

So do I fully submerge the spike each time and move it around in the liquid, or just drop it in?

-

Thanks, I can probably come up with some used coil springs, guessing that leaf springs would be equal. True?

Of course a used cutting edge from a snow plow would be harder, but do I ruin the hardness on any of these when I use a torch to cut them into pieces.

I'm easily wearing down the railroad spikes.

-

Howdy all, just a small time WY cowboy looking for advise from yall. New to this forum, found it trying to look up heat treating info.

A long time ago, needing a tap with none around to chase some threads a man showed me how to cut two grooves in a bolt, taper the leading edge, heat it red with a torch and cool it in motor oil. It worked, but doing some reading on this site brings up more questions.

I have a small pile of old railroad spikes, might be from the 1800's. Not sure which exact metal they are but I need/want to make them harder. I am using them in a homemade harrow to bust up the washboard bumps in my gravel road. They are about 3/4" square, maybe 8" long and have a bit of surface rust.

I can get some canola oil and all I have to heat them with is an oxy/acetolene rose bud torch. Should I be heat treating them or should I peen them with a hammer?

How do I harden old railroad spikes?

in Heat Treating, general discussion

Posted

Thanks very much, Laramie is a nice quiet town without much trouble going on. Let me know when you are ready and I'll stop by. My wife runs the Golden Prairie Bakery a few miles west of town, you are also welcome to stop by. I did find some railroad spikes so I'll try to not wear them all down to soon, although I just modified the harrow to carry twice as much weight.