-

Posts

19 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Silo house Dan!

-

-

what type of coal r u planning on using?

I just checked your profile out. Are you talking Kens custom? I'm there in February!

-

Well I was trying for information specific to Anthracite and this thread I thought was about it. I am working on a volumetric spread sheet on my ribbon burner design. waiting on a good quality gas flow meter. I dont think you could make one on a coal forge due to ambient interactions of the open fuel chamber... ?

-

17 hours ago, Another FrankenBurner said:

Metal is hot, nice job. Is that a ribbon burner or a blown tube burner?

The flame is spreed out in a 3" defusing pattern. Much like a rose bud. so directly facing material would be more evenly heated. Insulating brick could not handle the Pressures im exerting on them. As far as efficiencies When I'm working my tong materials (just getting started) the metal turns red way before the brick does. Yes insulating would be good if I needed to run burner longer than 5 mins or so. But then I would not be able to heat my coffee on it Like I do now. lol

-

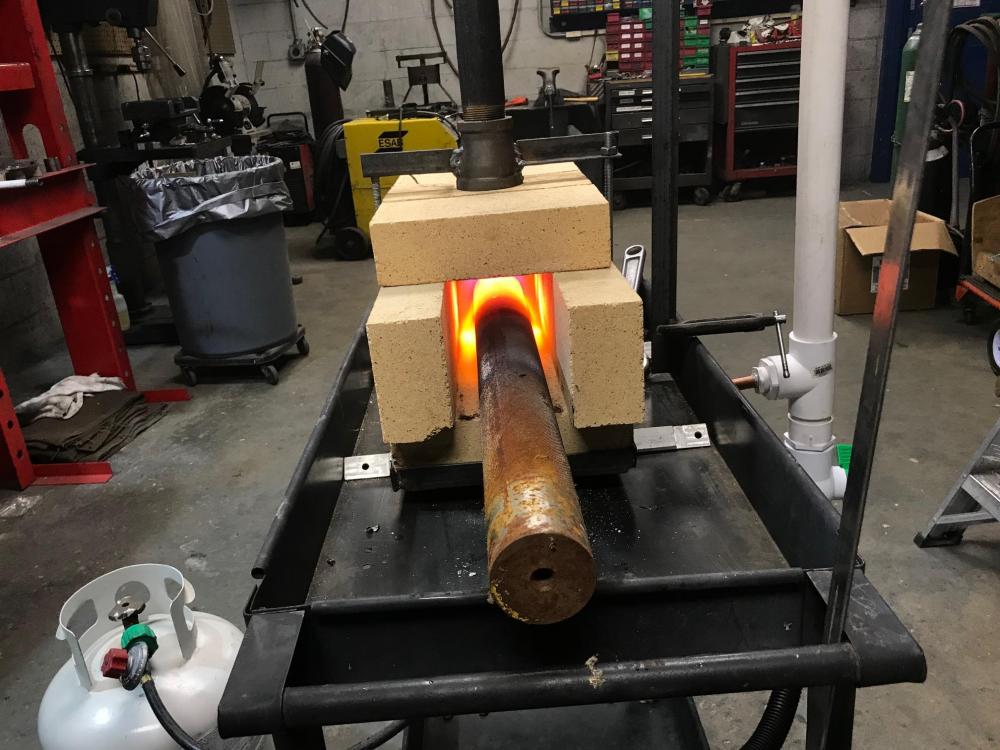

yes, ribbon from my research? Its 1'5 inch to 2" adapter mated to brick air tight. 12 or 14 holes drilled in brick 5/16. So the forced air mixes along the way & the adapter evenly distributes the air-fuel mix to chamber. I have a vid link here. if I CAN POST LINK. i BEING BANNED FOR IMPROPER USE OF QUOT??

-

yea, sorry Mod34 I dont understand your quoting rules? sorry

-

I guess I can try.... not sure if it's appropriate for a newbie to start new threads... at least in my tech groups I belong to they frown on newbie threads...

55 minutes ago, Silo house Dan! said:what does this mean? Edited 28 minutes ago by Mod34

Excessive quoting -

On 1/24/2019 at 7:54 AM, JHCC said:

"Optimum" is as much a function of what kind of work you're doing as it is of the kind of fuel you're using. Take some time to read over the posts in the Solid Fuel Forges section, and proceed accordingly.

One good option for you would be to start with a JABOD forge and use that to learn what size firepot will be best for your work.

oh believe me I have read up in here as much as I can, yes I've read about JABOD. I just want someone with real world experience to tell me , yes looks good start there or no way dude your a xxxx xxxx do this... I built a small brick ribbon burner now I'm looking for what I need to get to larger pieces of mainly decorative dressings on my silo house. . I have stair railings & balcony's, door knockers & large cedar wrought iron door (i'v already built but needs dressing) all the way down to drawer pulls, shelf brackets & such. See this is what I'm doing for my retirement. This in my fun time to enjoy life. Peace Out!

-

yes thomas I just got off the phone with her when I posted, she recommended the same thing. Thanks

-

Great read, but were can I find the "ideal size" pot size for my only local sourced TSC nut

- Anthracite

- 40 lb.

. Plus optimal BTU blower requirements.

I want to get this build right the first Time. So many conflicting options in here, I'm not sure what to do?

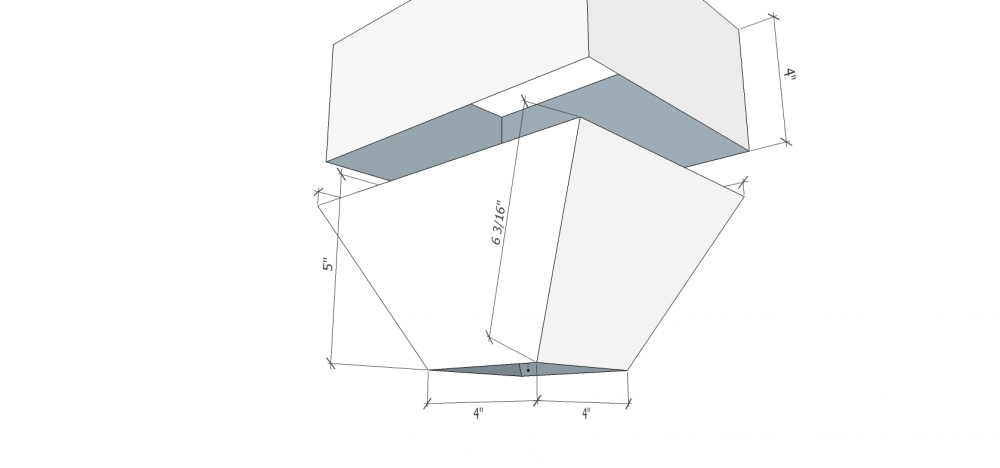

PLEASE direct me towards any useful information on this. i'll attach a 3d drawling I put together per info on u tube... ?

it seems too deep to me but hey what do I know..... That why I am here!

Thanks & Peace Out!

-

On 1/5/2019 at 12:17 AM, Charles R. Stevens said:

A bullet grate would raise the heart of the fire to table hight.

whats a billet grate?

-

On 1/4/2019 at 9:42 PM, Marc1 said:

Nice firepot, 12mm (1/2") thick? wow, good one.

OMG I have been looking for days trying to find such a link.. TY TY TY!!

-

OMG!!!! Why cant I find the section on coal forge designs... Is it me or this site, takes like 10 years to load a page & I cant get to where I want to go... I suck at typing but I'm typing faster that this page can keep up[ with........................

-

Yea I am lost, this started out as a reply to someone????

this was my first attempt at a ribbon burner forge. 1st forge of any kind actually. 2.5" cherry after in 10 mins in. it's alright I just made some more improvements last week end. I have a video that says to big to load.....

On 1/23/2019 at 12:52 PM, Another FrankenBurner said:An engineer who knows everything, how original...

All kidding aside, that is cool, what do you engineer?

All kidding aside, that is cool, what do you engineer?

Lately just my house, but mainly manufacturing production equipment...

-

On 11/29/2018 at 9:17 PM, Matt Watson said:

Just wanted to introduce myself. My name is Matt and I took a couple classes a few years ago and fell in love with blacksmithing but life kept me from it for a while. I have started setting my shop up and building my first gas forge. I prefer coal but I thought gas would be cheaper to start with. I have almost none of the right tools but I plan on making everything I need. Starting with a decent hammer. I have a 2.5 store bought cheap one to start with but I need to know what tools I need to make my first real one if anyone can point me in the right direction I have browsed through some of the forums but couldn't find what I was looking for. Also if there is anyone in here near me that would like to meet up and maybe show me a few things I would like to find some new friends that I can forge with every now and then.

hi Matt Where did you take your class at, Im scheduled for Feb. 6&7 at Kens custom Iron. The Gopher State" Minnesota. Its a was to go from Michigan but took an extra day to spend with family there.

-

On 12/3/2018 at 6:42 PM, VainEnd84 said:

What is your skill set, what tools do you have access to?

I'm an engineer... any & all I guess.

-

ok there are a 1000 plus replies here> Where do I go looking for a good burner DIY?

-

On 12/1/2018 at 7:17 AM, Matt Watson said:

Thank you that's good information. I will make another trip to my scrap yard and see if I can get some axles and springs.

I just heard from a local scrap-er that my local steel yard will not let no one scrounge around anymore. I guess someone slipped on a pile of steel and nearly cut there arm or leg off... That really sucks for me just starting out... re-purposing is my main goal for the silo house..

Recommendations for Working with Anthracite

in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

Posted

WOW never mind, dont like the tudes I jeep getting here.. I put up drawling, explained my self, asked question pertaining to Anthrasite. I give up.

Good bye Please delete me!