-

Posts

4 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by André Muchalak

-

-

There’s a technique called dambrascus, and it consists in heating the steel to a yellow color, then submerge it into a crucible with molten brass. The liquid brass enters through the pores of the steel and bonds with it... I read this in a book, but never tried... if you give it a shot, please make a review... cheers!

-

Well, thats odd, here the video seems to be ok.. I’ll try with another vid.

36 minutes ago, Latticino said:Not up on Kinyon hammers either, but to help diagnose for those in the know I suggest you give info on your compressor that is not just the storage size and maximum pressure, but the pressure rating at a certain airflow (i.e. 95 PSI at 11 SCFM). That being said, your tank size seems adequate and the maximum pressure is in line, however, big hard hitting air hammers are real air pigs. The Big Blue 110 hammer in our groups shop needed a compressor that cost almost as much as the hammer...

I’ll check that

-

Hello everyone! My name is Andre, I’m naturally from Brazil.

I am finishing my kynion style pneumatic hammer but I’m having a low bpm problem and I don’t know what is the main cause, since I have a 250L compressor running with 15bar.. this is the compressor.

My piston is kinda big, but I don’t think that it would be a problem to this compressor... it has 115mm on its base, and the arm diameter is 45mm ( don’t know if this is the right word)

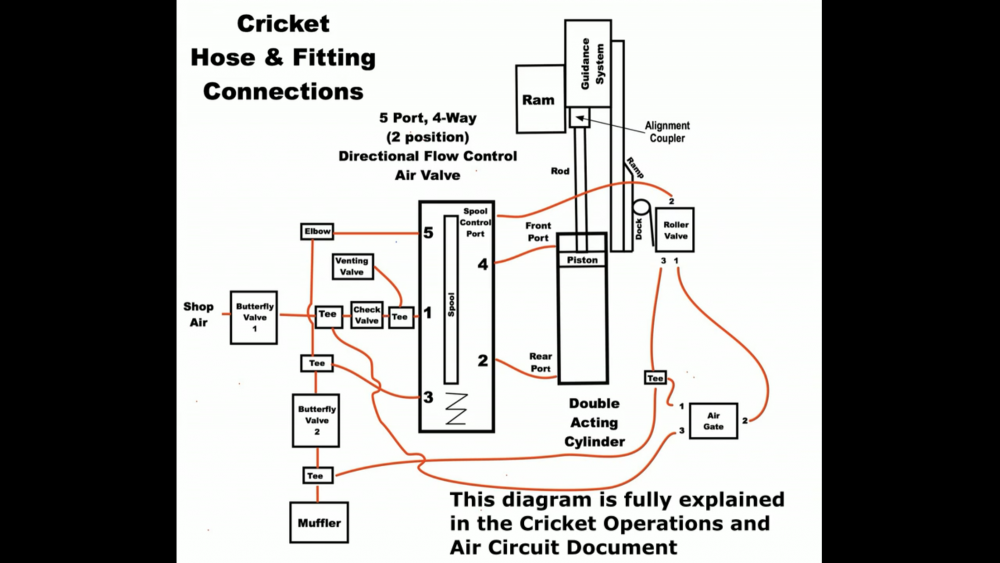

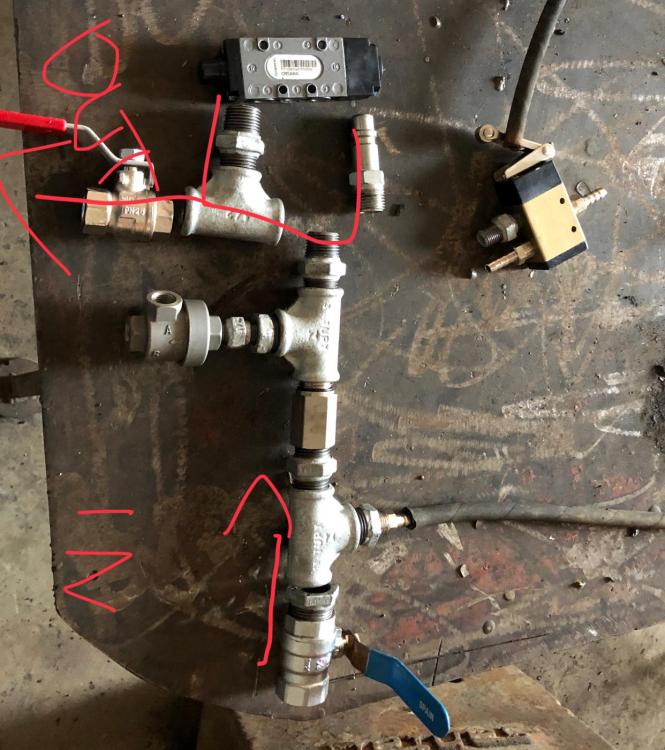

Ive based myself on crickets air circuit plans, but with only one roller valve ( maybe this is the problem)

(This is not the pilot valve I’m using, it’s just to use as example)

All of the main connections and the pilot valve are 1/2”, only the roller valve and it’s connections are 1/4”.

Here is the video of the hammer running... I’m hopping that someone will be able to help me! Thank you!!

Forging brass rod to steel

in Blacksmithing, General Discussion

Posted

Yeah, That’s what I meant... it is only for aesthetics, since brass is not hard enough to retain an edge... but it is beautiful to use as bolsters or guards...