Medic8126

-

Posts

7 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Medic8126

-

-

8 minutes ago, Nobody Special said:

I don't see any pins, how are your handles held on? Carry on, enjoy forging!

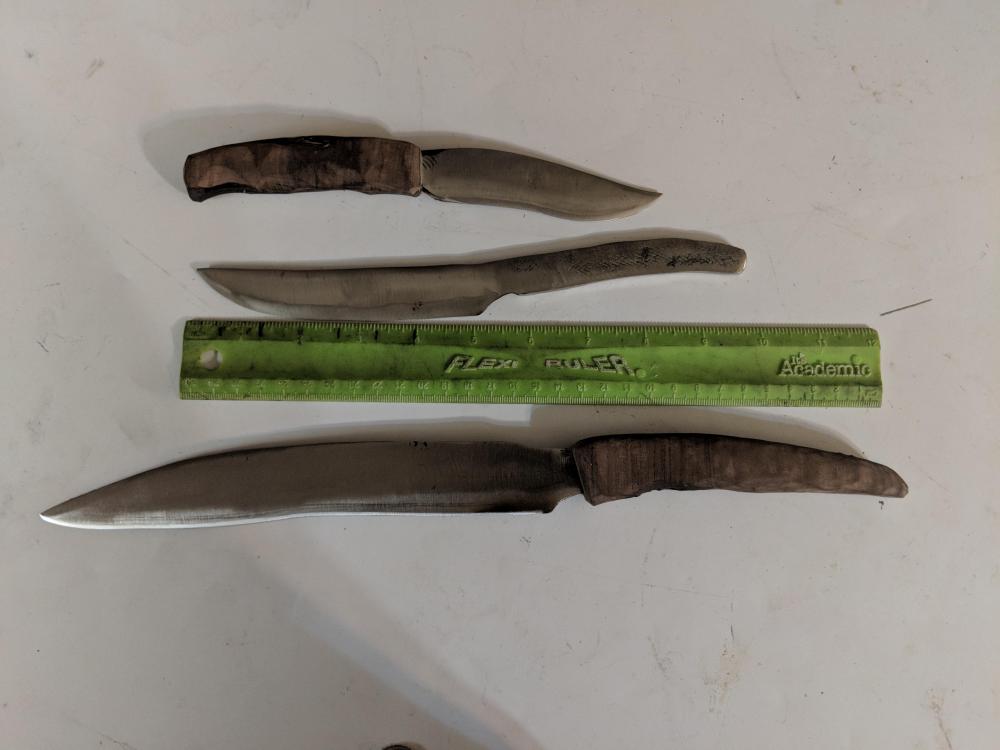

For the top one I split a piece of wood and carved out the inside to fit the tang then epoxied the two halves together with the tang inside. For the bottom one I drilled a guide hole in a block and burned in the tang then added epoxy to make sure it couldn't come out. For the middle one I'm still trying to decide how I want to do it. I may go with pinned scales but I'm not sure yet.

Anyone have any suggestions on what I should do for the handle on the middle one?

-

So here are the results of my first couple days of having a forge. These are the first 3 knives I made. I'm having quite a bit of trouble with the grinding as all I have is an angle grinder right now. Even having only done this a few times over the last couple days I have learned a ton and realized there is so much more I need to learn. Criticism is welcome as I believe it's the best way to improve.

-

1 hour ago, Steven511 said:

without something like ITC or Satanite your lungs are gonna have a bad time breathing in fiberglass dust.

Thanks for the advice. I read about the dangers of inswool so I made sure to wear a respirator when I fired it. Today it's getting a coating of ITC.

-

-

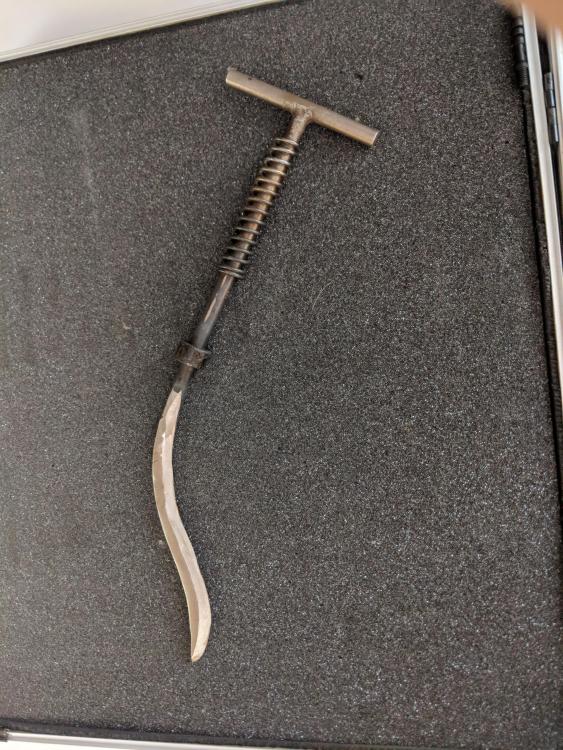

Well I finally built my first forge. The outside is made out of some stainless I had laying around. The inside is insulated with 2" of inswool with 1/2" of kastolite 30. I have an interior area of 4" tall x 7" wide x 11" deep. I'm using a simple forced air burner. I fired it up for the first time last night and today I'll be coating the inside with ITC-100.

-

Results of first week of making

in Knife Making

Posted

What would you recommend as a good file to buy. The only ones I have now are just harbor freight junk that I use for wood. I've heard that Nicholson files aren't so great since they started producing in Mexico.