-

Posts

9 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Allomancer Jak

-

-

I was just wondering if there is a list in general. I'm not necessarily looking for one thing in particular, but I thought it would be good to know if such a thing exists for when I need to make informed decisions on purchases. Reviews are good, but I don't always trust them because the write might be using a product for a completely different application.

-

Ok, I appreciate the advice, and I have started reading through Burners 101. As you mentioned, space is an issue, and that's one of the reasons the C-C forge appealed to me. My primary use for it would be heat treating, not forging. I'm not sure if that makes a difference as to your advice though. Right now I'm just trying to find a local supplier of refractory materials.

-

17 hours ago, Mikey98118 said:

BTW, what are you planing to use for a burner? If you are about to say that it will be an air-propane torch, I suggest you read the thread called Burners 101, because the only way that torch can be stopped from overheating, is to aim it at the opening (burner port) from outside; it will then do a lousy job of heating your forge.

Thanks for the tip! Very good to know.

-

-

Thank you all! This is very helpful.

-

I appreciate the warning, but I'm still not clear on my initial question. Is there a minimum amount of oil I need?

-

Is there a proportion of oil to steel as to how much oil to use when quenching? I just want to make sure I will be using enough, since I've never made knives on my own before. If I don't use enough, will the oil get too hot and not harden the steel?

-

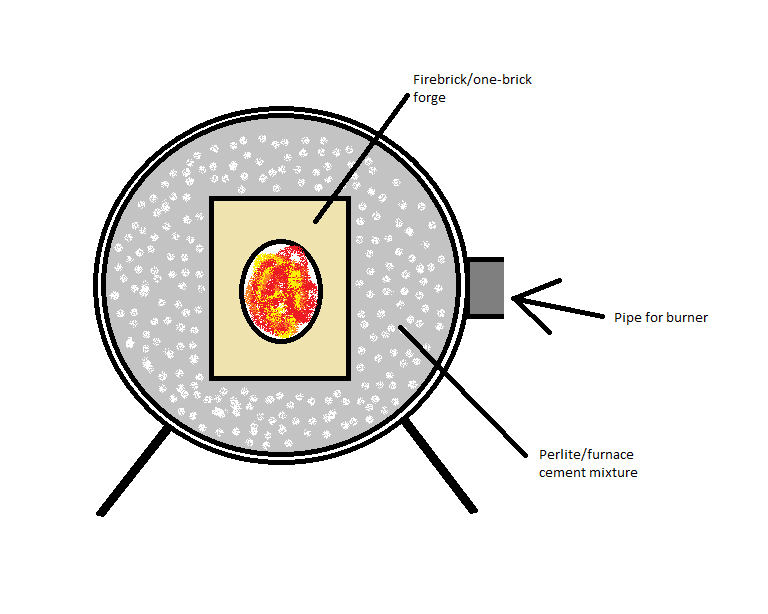

I'm making a coffee can forge to get my feet wet, and I'm planning on using perlite for a refractory lining. I've been seeing some people say to use sodium silicate to bond it, and others say to use watered down furnace cement. Which would be better, and how long would each take to cure? My plan is to have a second, inner lining either way. Any hard facts would be welcome!

Is there a list of recommended products/brands?

in Blacksmithing, General Discussion

Posted

You guys are silly

Thanks anyway, I appreciate the responses.