-

Posts

6 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Inflight

-

-

-

-

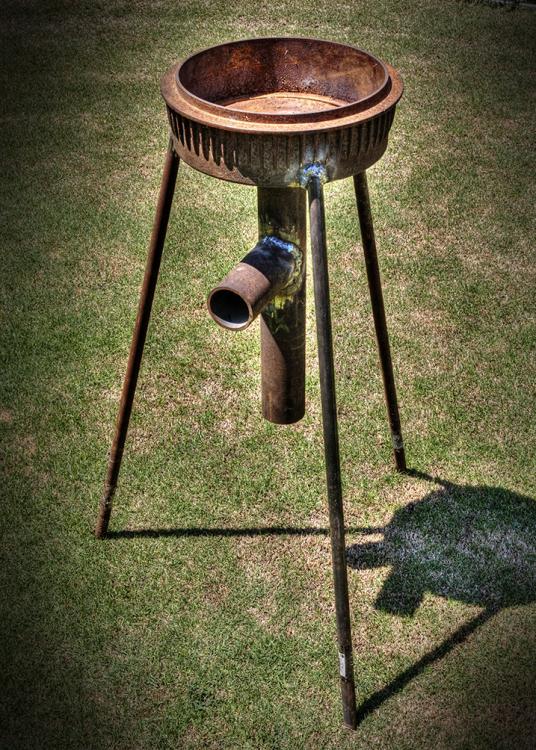

Recently I've added a coal tray of about 2 ft square around the brake drum which allows supporting longer workpieces, more coal to coke up, and I can pile the hot coals much deeper. So far it's worked out very well.

And today I found the name Peter Wright in the side of the anvil.

Matt

-

-

My name is Matt and I'm from Long Beach, CA. Very new to blacksmithing but I have lots of experience working metal in my home machine shop.

I recently acquired a 200 lb anvil and I built a brake drum forge. My first projects will probably be some simple tools such as punch & drifts as well as tongs.

Here are a couple pictures of the anvil and my forge during construction. And No, that is not the hammer I plan on using...it was just for staging the photo.

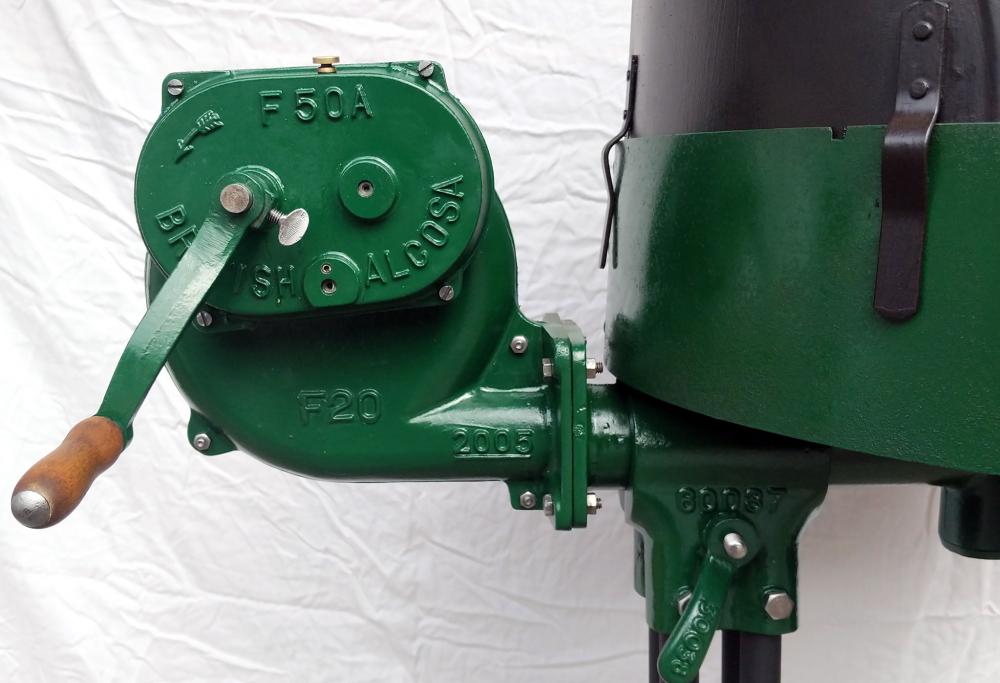

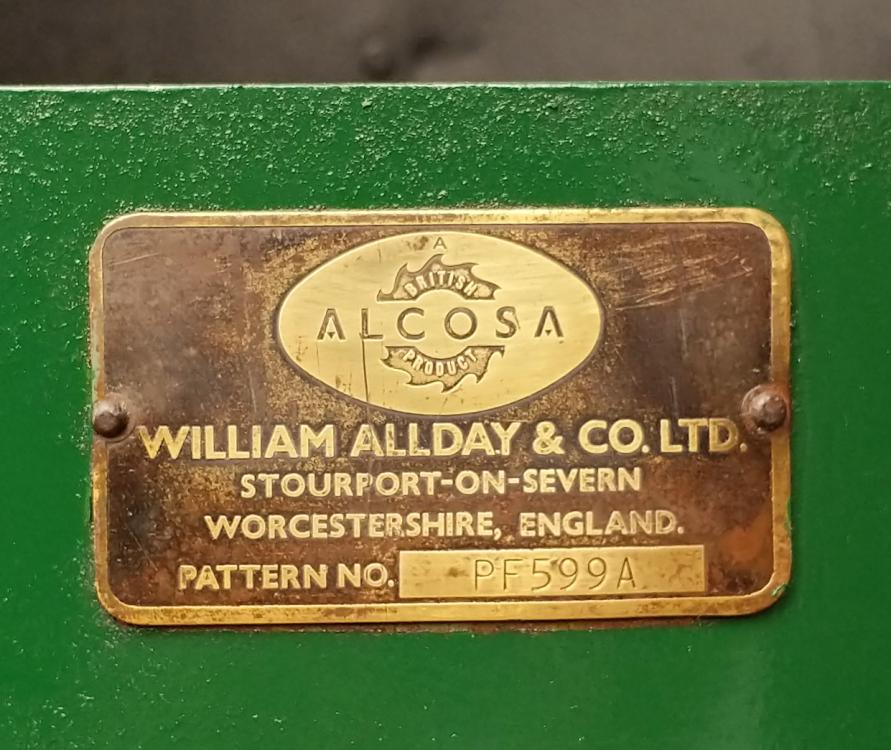

new William Allday & Co coke forge

in Solid Fuel Forges

Posted · Edited by Mod30

Remove excessive quote.

Thanks, Irondragon! I abrasive blasted and painted everything, inside and out. I was told the hand-crank gearbox leaked oil, so I flattened all the mating surfaces and used permatex RTV gasket material to seal everything. I've done a couple heats with coke and it works well.

I've seen the images and read the company history on gracesguide.co.uk.

Thanks again,

Matt